TRAvel Slicer: Continuous Toolpaths

We developed the open-source Travel Reduction Algorithm (TRAvel) Slicer to enable the printing of complex 3D models on a wider range of printers and in a wider range of materials than is currently possible with traditional slicing methods.

Years:

2024-current

Collaborators: Jaime Gould, Camila Friedman-Gerlicz, Leah Buechley, and other lab members

Publications:

Jaime Gould, Camila Friedman-Gerlicz, and Leah Buechley. 2024. TRAvel Slicer: Continuous Extrusion Toolpaths for 3D Printing. In The 37th Annual ACM Symposium on User Interface Software and Technology (UIST ’24), October 13–16, 2024, Pittsburgh, PA, USA. ACM, New York, NY, USA 17 Pages. https://doi.org/10.1145/3654777.3676349

Printing in Continuously Extruding Materials

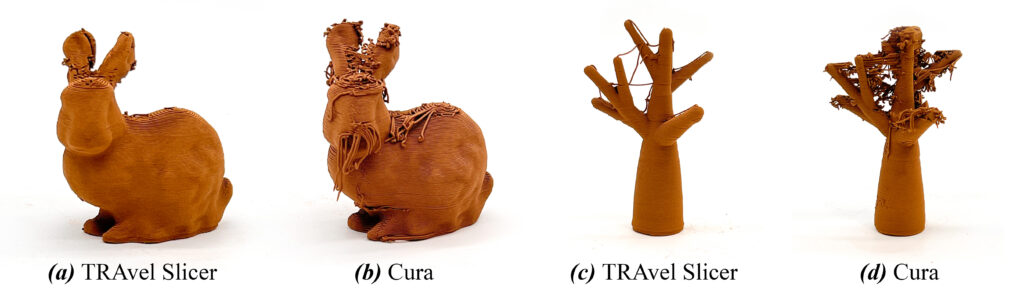

Traditional slicing software was written and optimized for printing on Direct Write 3D printers in thermoplastic monomers like PLA (polylactic acid), PETG (polyethylene terephthalate glycol), and ABS (acrylonitrile butadiene styrene) that are able to start and stop extruding quickly without depositing extra material. Paste-like materials such as a novel bronze material we developed here at the Hand and Machine Lab called CeraMetal continues to extrude even when the printer sends the command to stop. Models printed in continuous extrusion materials with toolpaths generated by traditional slicing software like Cura fail or result in unviable prints.

TRAvel Slicer was developed in order to reduce the number of travel movements both inside and outside the model so that the toolpath prints as continuously as possible with fewer stops or transfers to a different part of the model.