CeraMetal: Metal 3D Printing with Clay

CeraMetal is a novel approach to desktop metal 3D printing using a custom metal clay. Our approach, which was inspired by jeweler’s metal clay, is significantly more cost effective and accessible than traditional approaches to metal 3D printing. We aim to enable a broad range of people to experiment with 3D printing metal in an everyday context.

Years:

2022-current

Collaborators: Leah Buechley, Jaime Gould, Fiona Bell, and other lab members

Publications:

Leah Buechley, Jaime Gould, and Fiona Bell. 2024. CeraMetal: A New Approach to Low-Cost Metal 3D Printing with Bronze Clay. Proceedings of the 2024 CHI Conference on Human Factors in Computing Systems (CHI ’24). Association for Computing Machinery, New York, NY, USA. https://doi.org/10.1145/3613904.3642155

Material and Workflow Development

Our custom metal clays are materials that behave similarly to traditional clay before they are fired. They can be 3D printed using clay 3D printers. Once fired, using a custom firing schedule, the metal clay sinters into a solid metal part. The clay making process is shown below.

We developed and investigated three different Bronze clay recipes. We tested each mixture’s printability, structural stability, and tensile strength to understand how different binding ingredients in the clay affect these properties.

Software

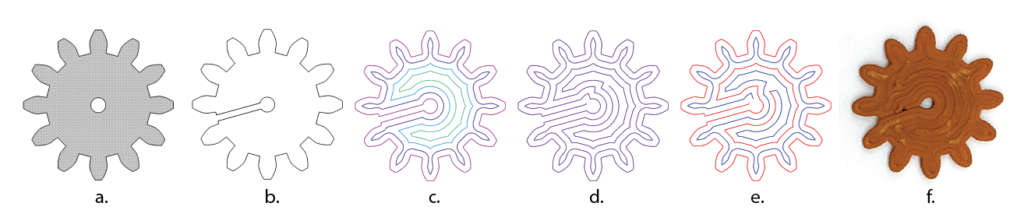

We are currently developing custom slicing software for metal clay and other non-tradtional 3D printing materials. The software generates 3D printing toolpaths with no or very limited travel moments. Our software takes an imported 3D model and generates a continuous path for the 3D printer to follow based on Fermat spirals. The steps that our slicing algorithm follows for each layer of a part are shown below.

Artifacts

We have used our custom clay and workflow to print a range of artifacts including working gears, tools, and jewelry.