Introduction

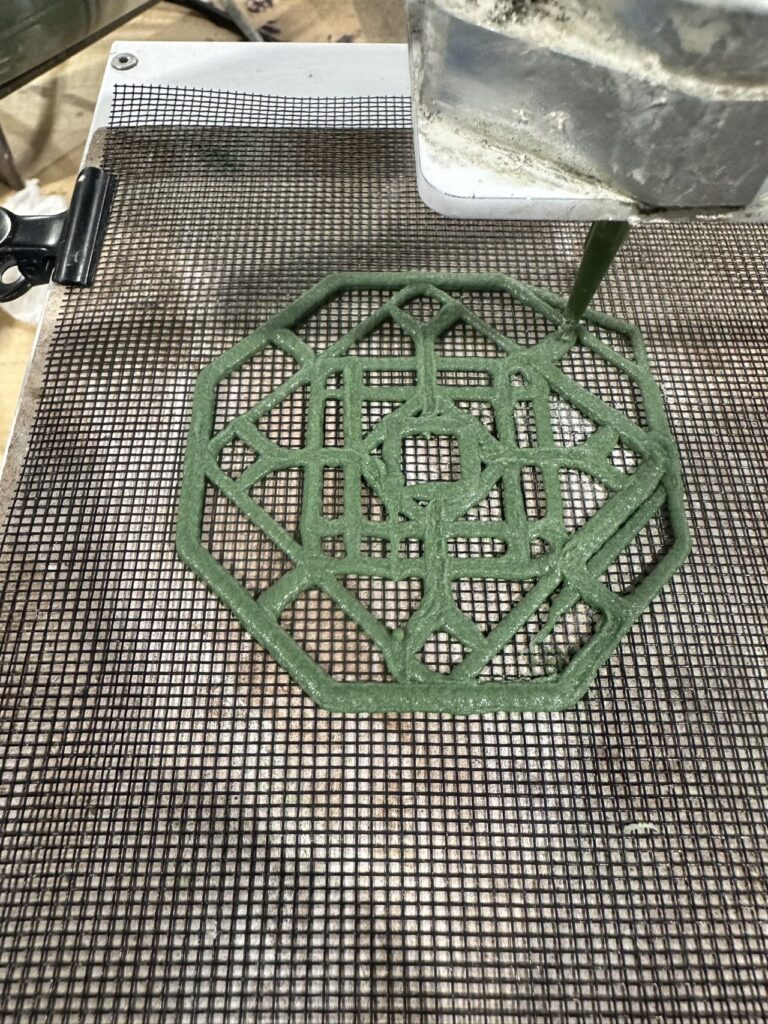

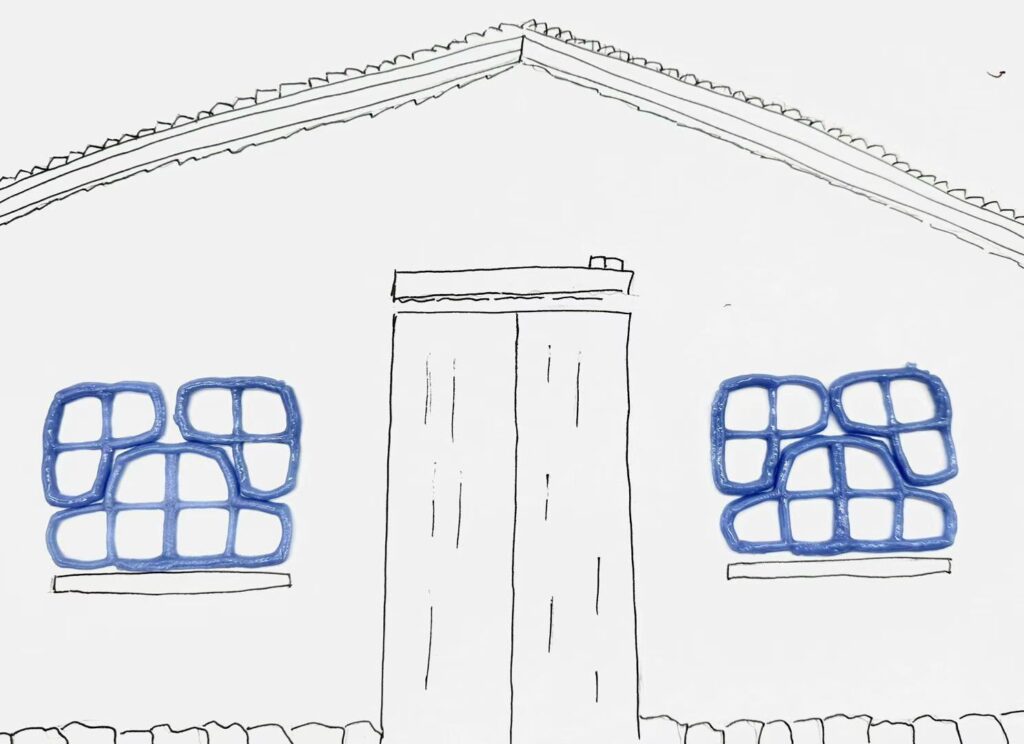

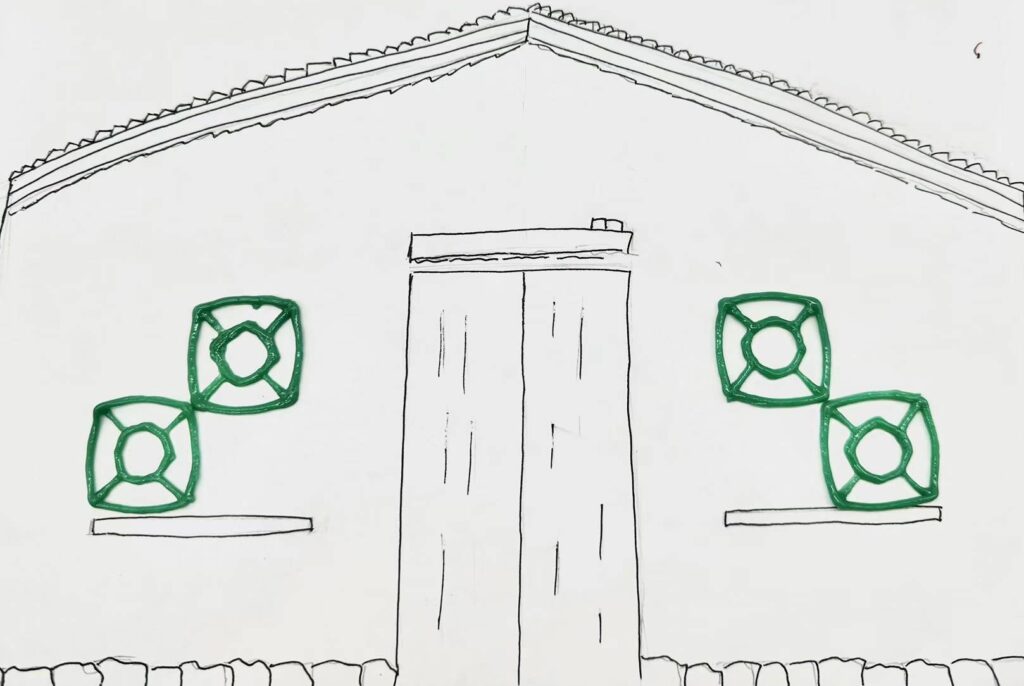

In the Final Project, I chose to print glass with Chinese windows and window grilles as the theme. Because the Toolpath generated by Cura has too many travel paths, I chose to use Turtle Library to write my own Toolpath, and the final effect was improved. In addition, based on the glass frit, the Eazon printer was used to extrude the material to complete the final printing.

Background Research

I’m very excited about my project this time. I’m particularly interested in exploring “extrusion materials”. Before this, I often used PLA materials, and the development of materials seemed to be limited, but extrusion materials seem to have a wider development space. Commonly used extrusion materials are clay. Of course, we can also mix glass frit with other thickeners to obtain printing materials with extrusion properties. The previous clay printing assignments I completed this semester have been very helpful for me to use glass frit printing this time.

In addition, the experience of writing Gcode assignments based on turtle library in the past few times has enabled me to use python to complete the toolpath I need more quickly.

Related work:

1. An Algorithmic Approach to Chinese Lattice Design

In this paper, it provides some rules and algorithms for people to design some complex patterns of windows.

2. A Journey through Chinese Windows and Doors – an Introduction to Chinese Mathematical Art

It demonstrates many different, interesting and traditional patterns of chinese window which inspire me a lot.

3. Shape Grammars of Ice-ray Chinese Lattice Designs : haldane liew (mit.edu)

4. CeraMetal: Metal 3D Printing with Clay – Hand and Machine This article from Hand and Machine Lab, which mentions the recipe for metal clay and the slicing algorithm that can be used, has helped me a lot in my project.

Process

My project includes 4 processes in total, designing the toolpath of the window grilles, making glass printing materials, printing with Eazao printer, and firing in the kiln.

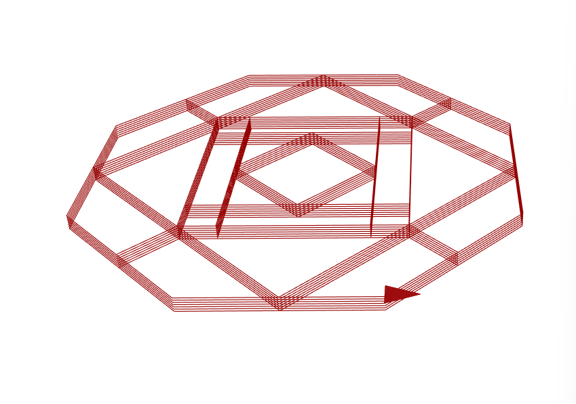

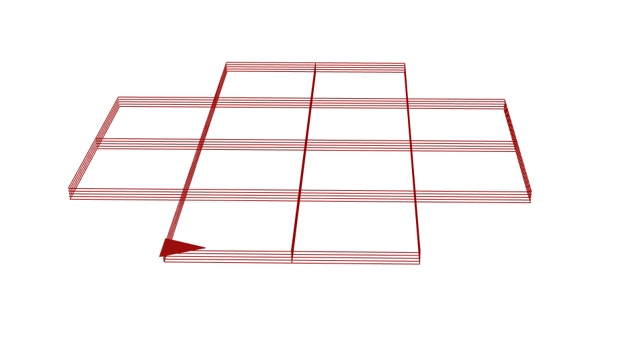

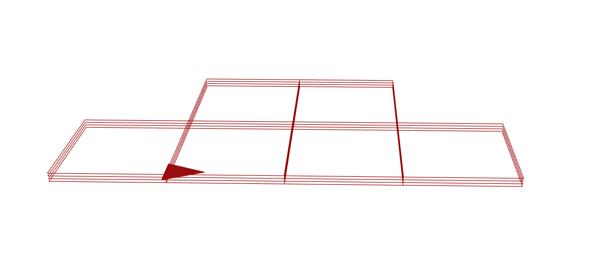

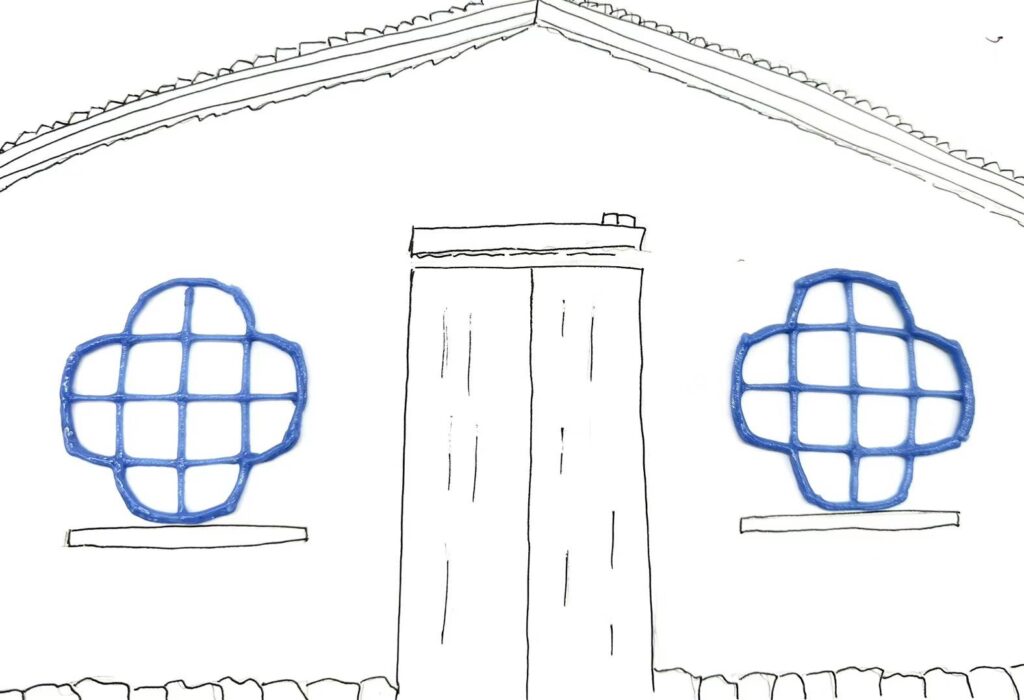

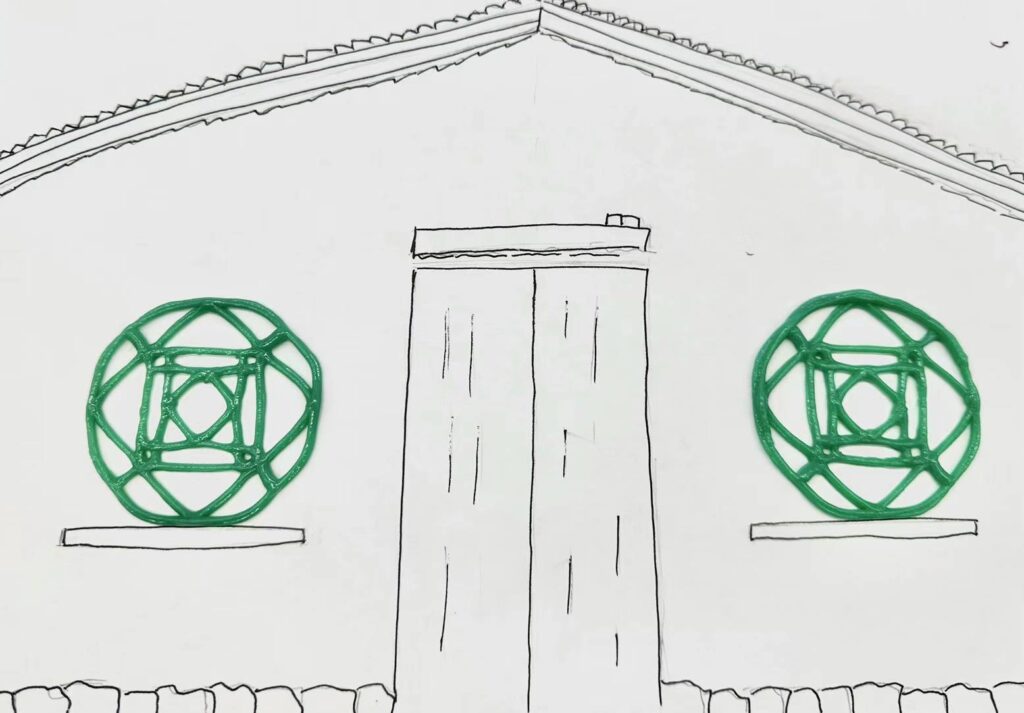

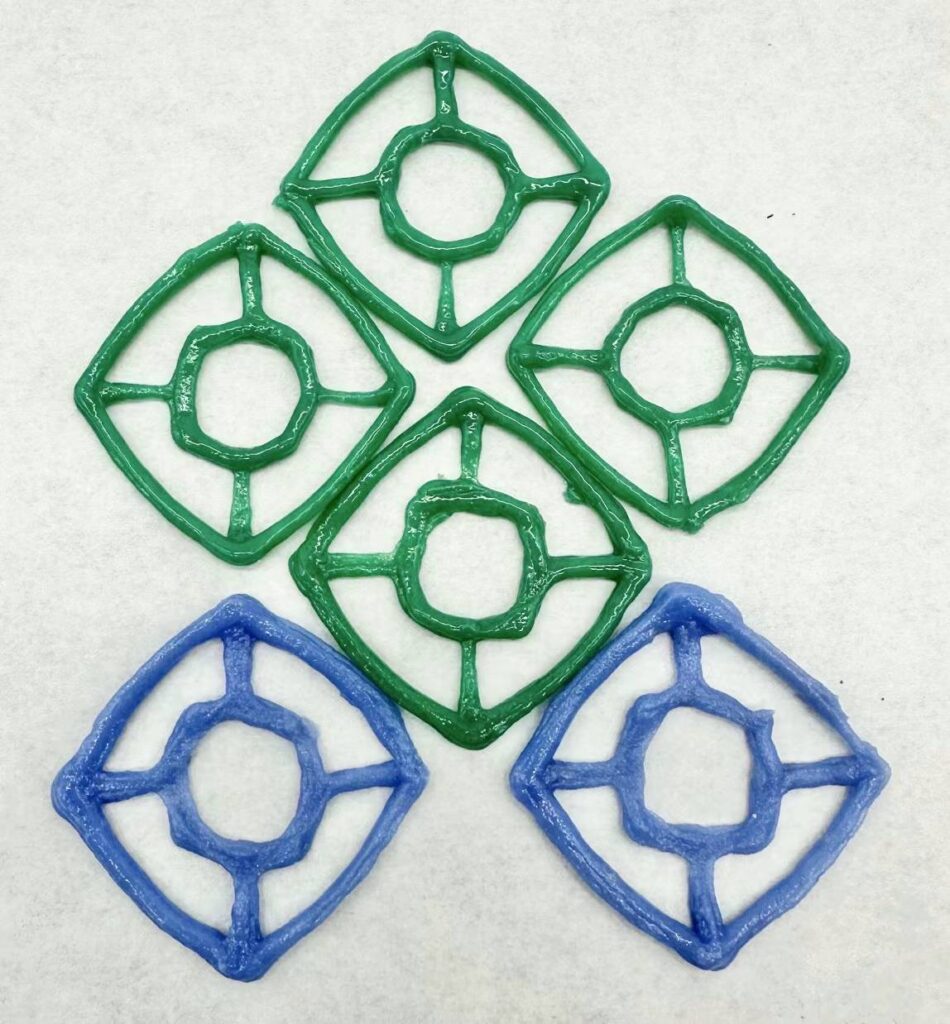

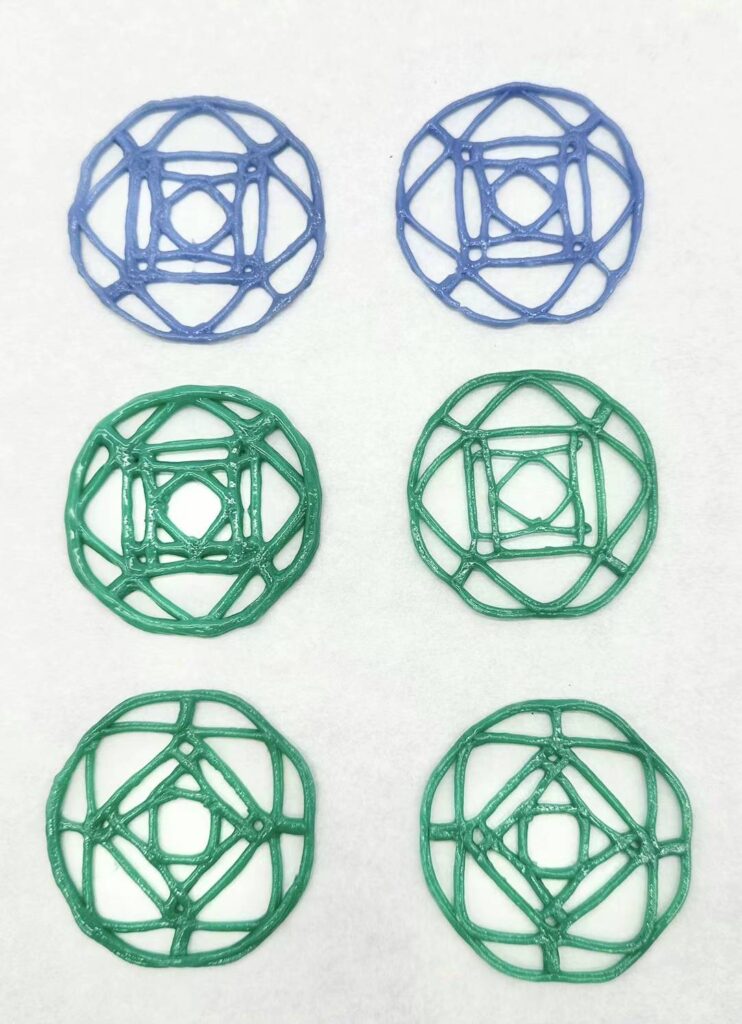

Designing the toolpath of the window grilles

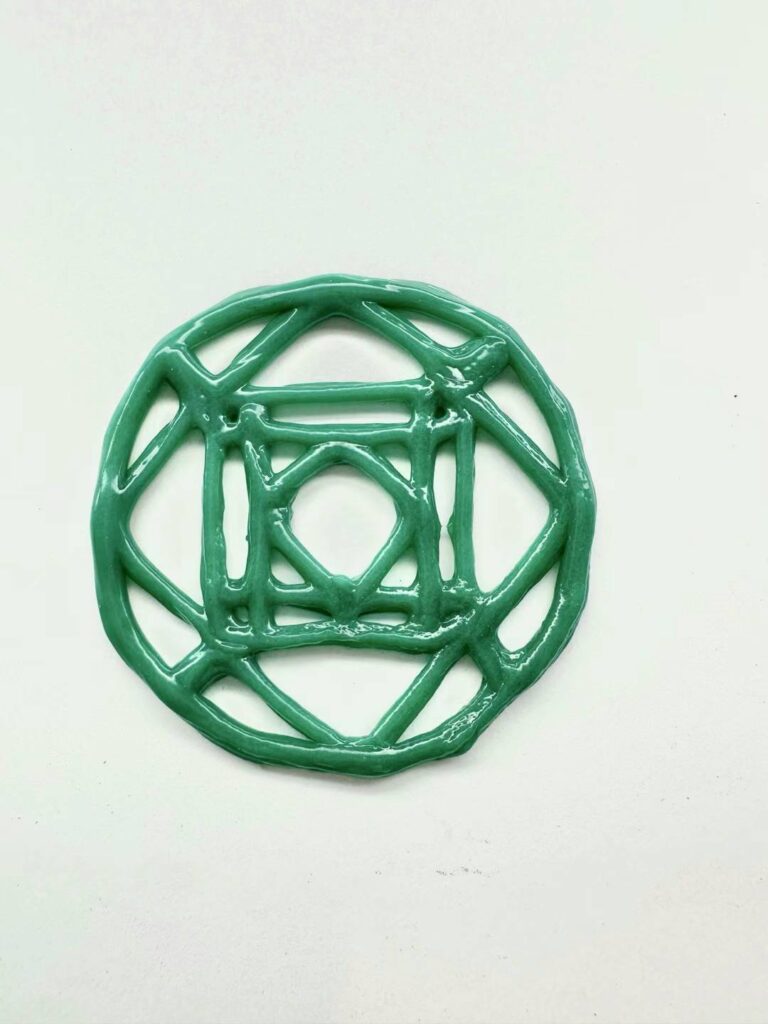

Because the extruded material is not like PLA, which becomes hard enough when it is extruded, the glass material is very soft, so when the nozzle moves, the material will continue to extrude even if you give it the instruction of t.penup() not to extrude. So I have to design a path with as little travelpath as possible, and make the nozzle avoid contact with the printed part when moving. In order to achieve better printing effect, I gave up some complex window grille structures and chose a simple structure.

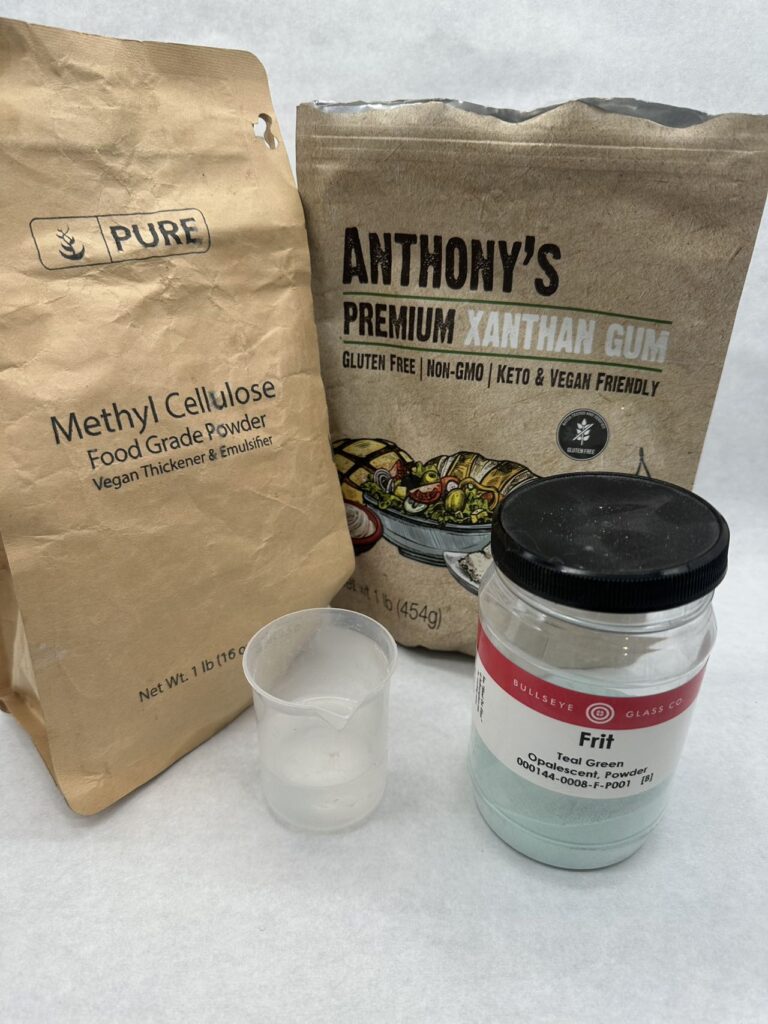

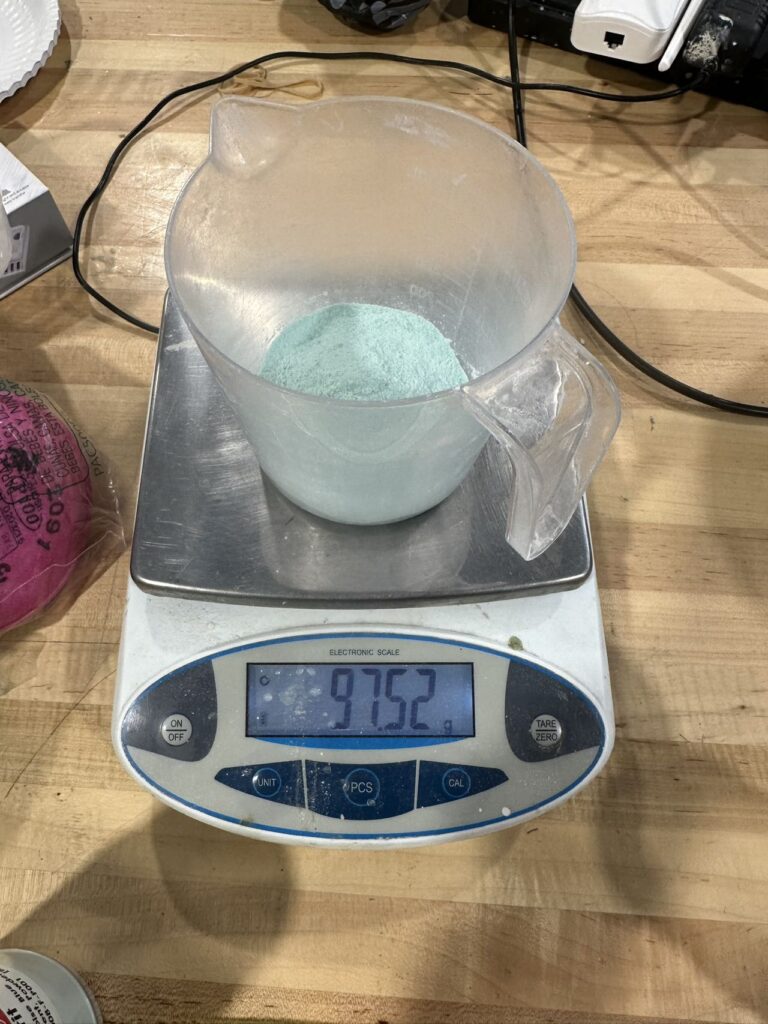

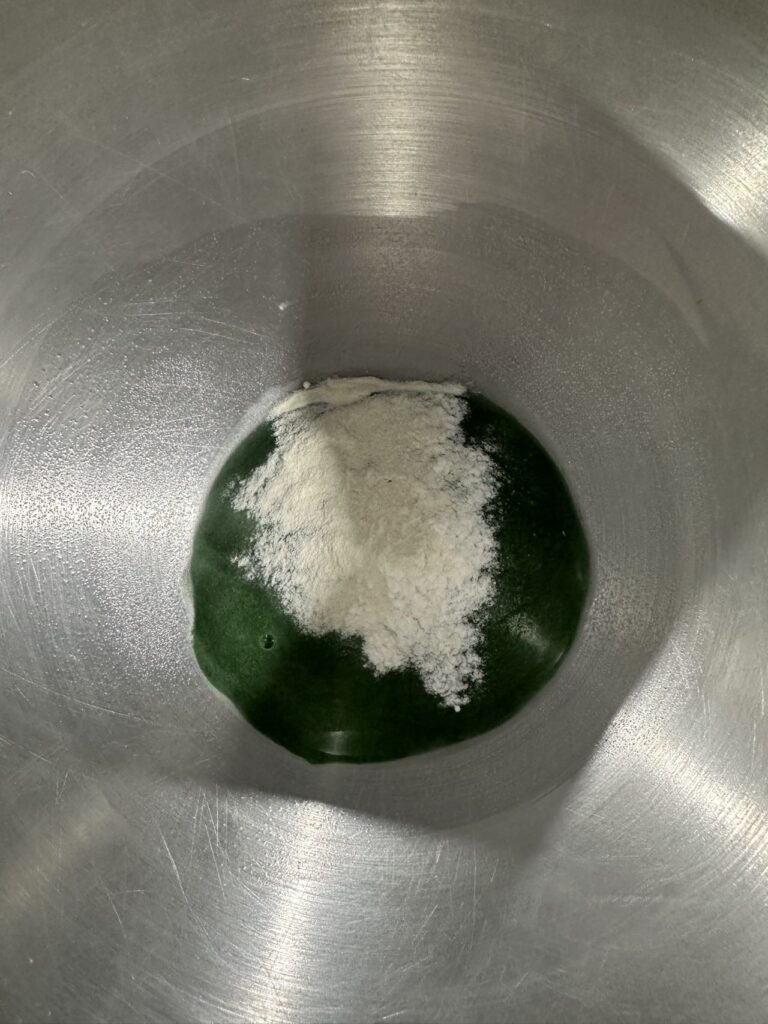

Making glass printing materials

Glass printing materials mainly include 4 parts, glass frit, xanthan gum, methylcellulose and water. In this process, you need to wear a mask and gloves. After mixing the materials according to the formula, you need to use your hands or a blender to make the materials into a soft and sticky paste. Make sure that the mixed materials have no lumps and bubbles, and try to squeeze out the remaining air in the materials. In addition, the glass printing material is recyclable. I recycled some of the failed printing items and remade them into new printable glass materials.

Printing with Eazao printer

When printing, I usually hold tweezers to monitor the whole process, because the nozzle will collide with the printing part during the extrusion process, resulting in some burrs, or printing unexpected materials, so I need to use tweezers to remove these excess parts. After printing, I also need to perform secondary trimming to make it look more regular. After printing, the object is still soft, and we need to put it in a heating box to heat it to dry and dehydrate it, and form a fixed hard shape.

On the left, the nozzle destroys the printed layers when moving. On the right, by improving the ToolPath route, the travel path can be reduced, thereby reducing the damage to the printed parts.

Firing in kiln

Put the dried printed object into the kiln and set the parameters. This process will eventually take 6 hours.

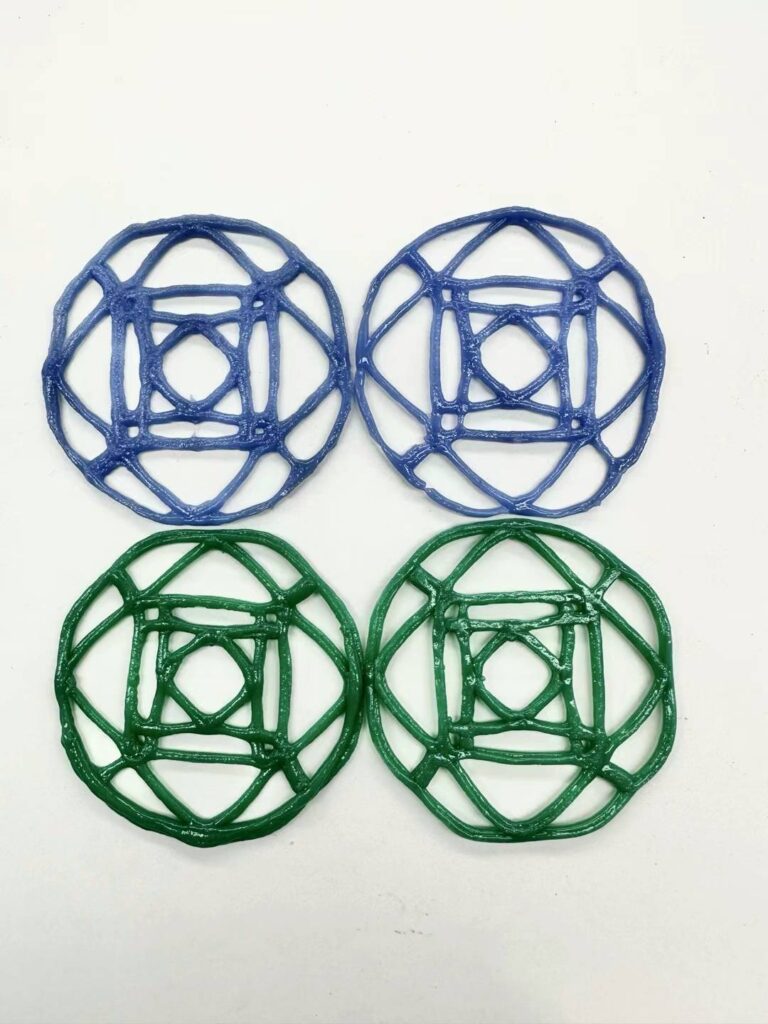

Outcome

Future Work

In the future, I would like to continue exploring extrusion materials, such as metal powder materials. Compared with the decorative properties of glass, metal materials have more practical properties and can be used in daily life.

Reflection

In this project, I have a deeper understanding of extruded materials, and a better understanding of what materials can be extruded and printed. In addition, I have a better understanding of how temperature changes affect the firing of glass. The chemical changes that occur during the firing process, and the slight temperature differences will have completely different firing results, ash and beautiful glass.

In addition, I have a deeper understanding of the Eazaon printer. The printing process is how to slowly extrude the material from the propeller, enter the motor through the duct, and finally extrude it from the nozzle. This structure is huge, precise, and complex, but if you separate it into parts to understand it, you will have a better understanding of the structure of the printer. I wonder if it is possible to make a “printer that extrude materials” by yourself. I guess the biggest challenge here is some electronic parts and the motherboard. I will also explore this direction in the future.