Introduction

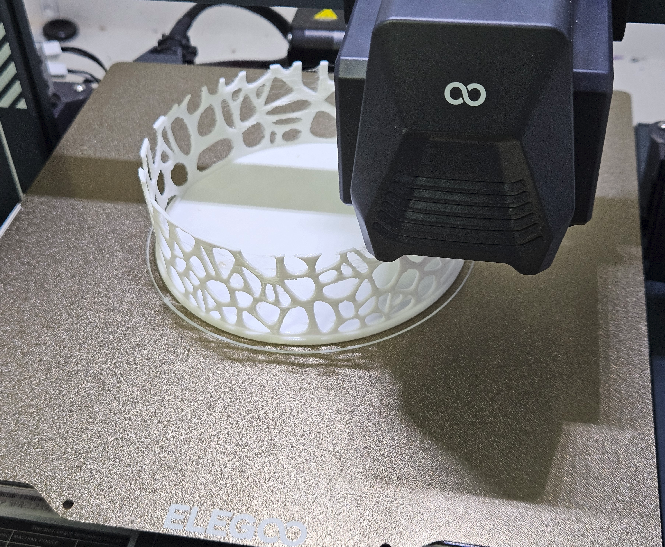

In this project, I aimed to combine computational design and digital fabrication to create a set of three 3D-printed pots tailored specifically for my orchids. Orchids require excellent airflow around their roots to thrive, and the design of my pots aims to address this need by incorporating Voronoi patterns into the pot walls. Voronoi patterns are not only visually appealing but also allow efficient material use while preserving structural integrity.

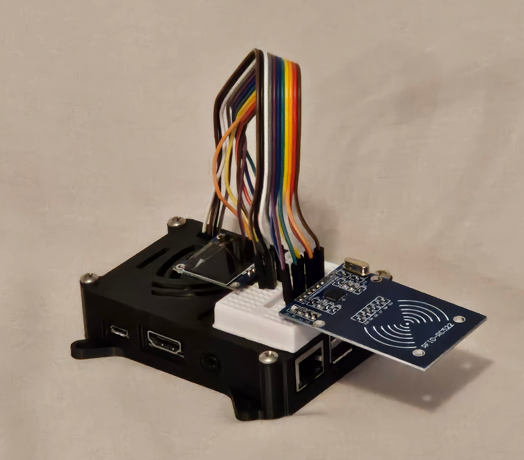

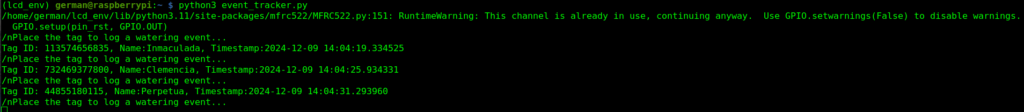

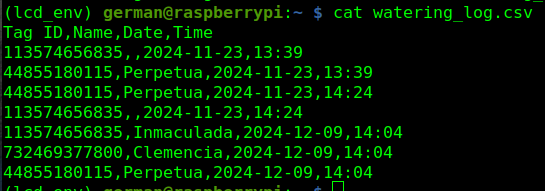

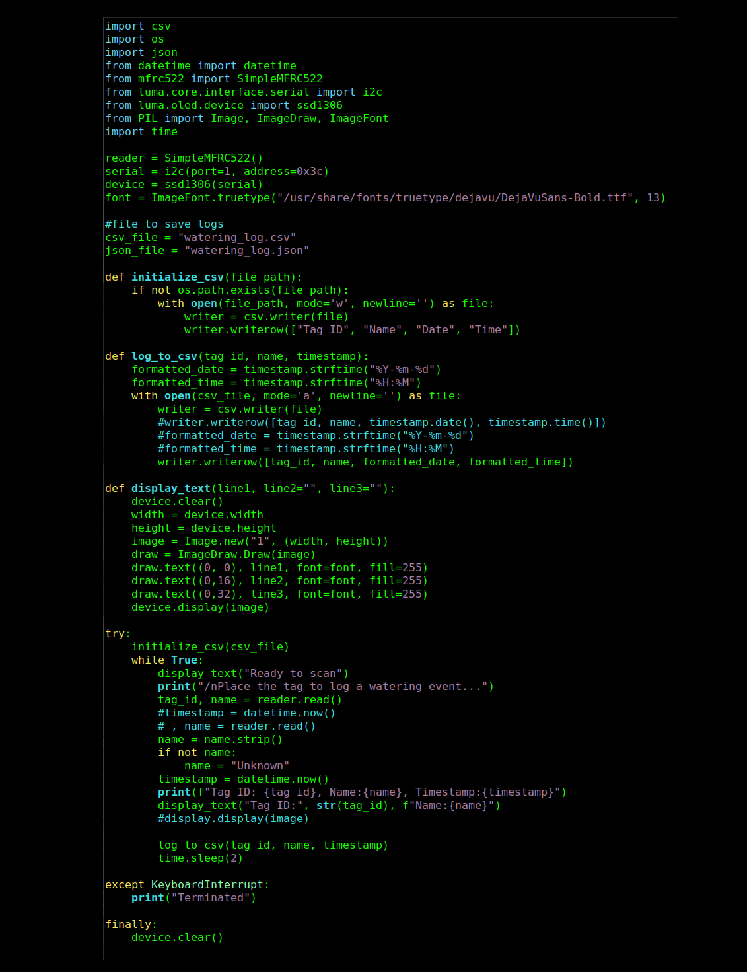

To enhance the functionality of my pots, I integrated an RFID-based tracking system. Each pot is assigned a unique RFID tag that allows tracking of watering events. A raspberry Pi with an RFID reading module logs these events, recording timestamps, tag IDs, and name in a CSV file. This system provides an improved way of monitoring my plants over time.

The pots were fabricated using TPU filament, chosen for its flexibility to prevent damaging the delicate roots of my orchids during repotting. The combination of computational design, material experimentation, and IoT integration demonstrates the potential of digital fabrication to address practical challenges creatively.

Background Research

Voronoi Patterns and Material Efficiency

Voronoi tessellations have been widely studied for their ability to create lightweight structures while maintaining strength and stability. As discussed in the paper Voronoi cell analysis: The shapes of particle systems, these patterns occur naturally in biological systems such as cellular structures, where material efficiency and functionality are critical. This property inspired the design of my pots, where the Voronoi pattern reduces material usage while ensuring enough structural integrity for the delicate orchid roots. The tessellations also provide a visually appealing design, blending functionality with aesthetics.

Orchid Care and Airflow

Orchids roots require excellent airflow to mimic their natural environment, which typically involves growing on the bark of trees. The perforations of the pot design, achieved using the Voronoi pattern, addresses this need by allowing air to circulate freely around the roots. This airflow promotes healthy root development, and reduces the possibility of root rot.

IoT Integration and Scott Hudson’s Work

The RFID tracking system used in this project draws inspiration from Scott Hudson’s concept of upcycling everyday objects into IoT-enabled devices. His work on the IoT Codex mentioned in his paper An Upcycled IoT: Building tomorrow’s IoT out of today’s household possessions, demonstrates how simple and low cost technologies like RFID tags can be integrated into mundane objects to enhance their functionality.

To implement the RFID system, I relied on the RC522 module, a commonly available and used component for small-scale IoT projects. As described in the article In-Depth: What is RFID? How it works? Interface RC522 with Arduino, the RC522 module is a low cost and efficient way to integrate RFID technology into microcontroller based systems. This module communicates with the Raspberry Pi to log watering events by reading the unique ID of each pot’s RFID tag. The step-by-step tutorial in the article provided valuable insights into the functionality and configuration of the RFID module, allowing me to integrate it into my system without major issues.

In this project, the integration of RFID tags with each pot allows for automated tracking of watering events, transforming the pots into “smart” objects that log care schedules in a seamless fashion. The approach aligns with Hudson’s vision of enabling end-users to repurpose existing objects with IoT capabilities, minimizing waste and maximizing utility.

Combining Computational Design and IoT

This project uses computational design techniques, such as the application of Voronoi patterns, along with IoT integration to address practical challenges in plant care. Tutorials and online resources provided guidance on implementing Voronoi patterns in Grasshopper and Rhino, allowing me to create my pots tailored to be both functional and aesthetically appealing. By combining these elements, my project demonstrates the potential of digital fabrication to innovate and enhance everyday objects.

Process

Computational Design

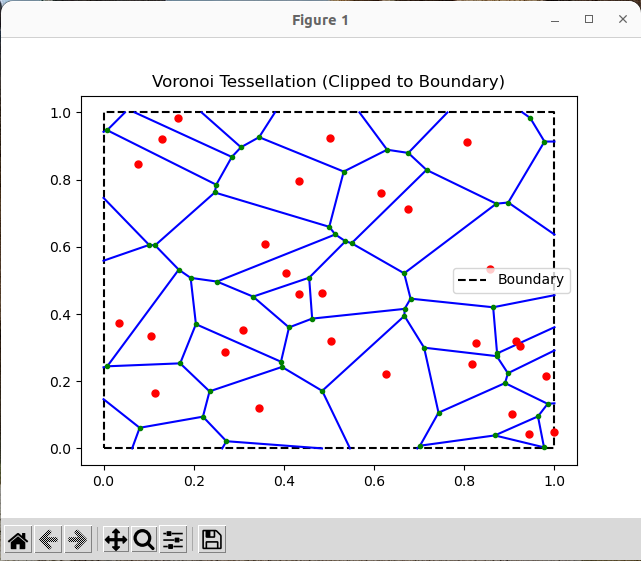

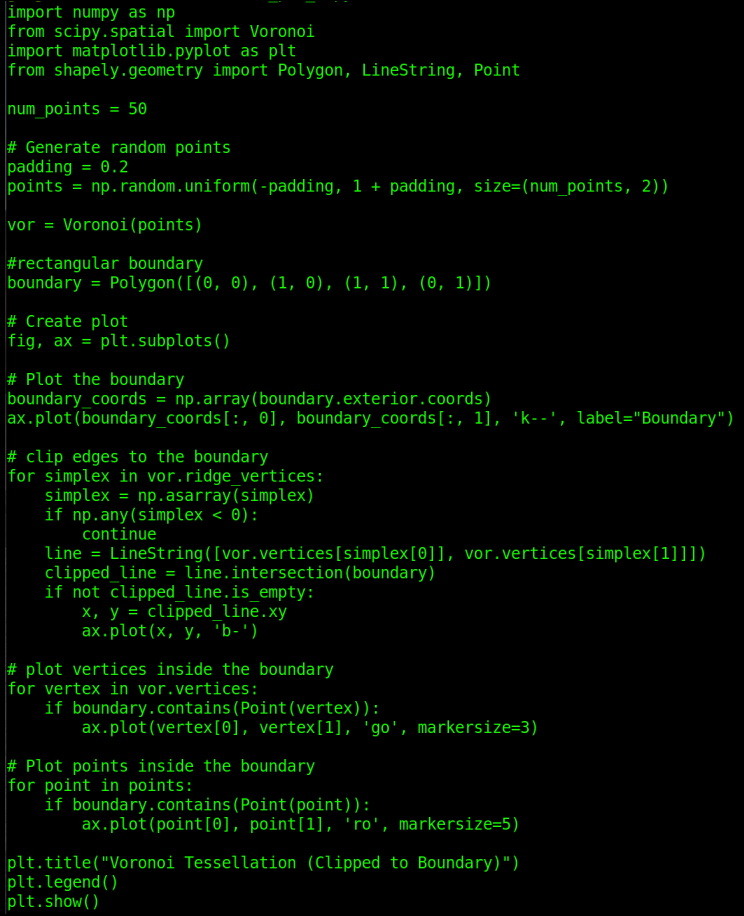

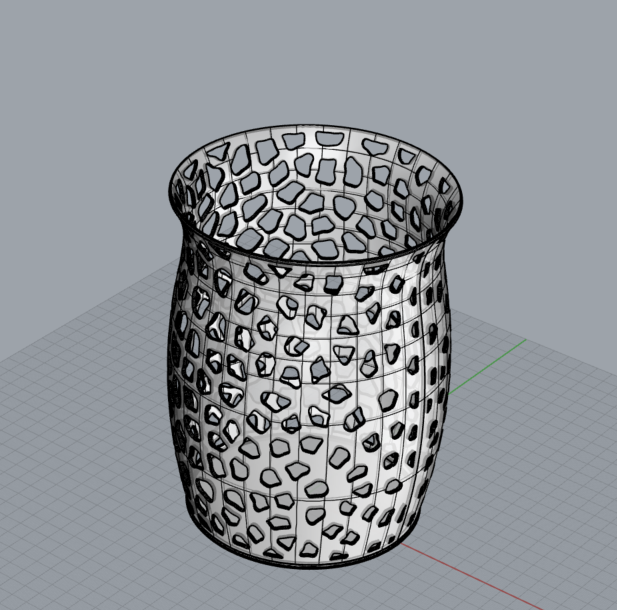

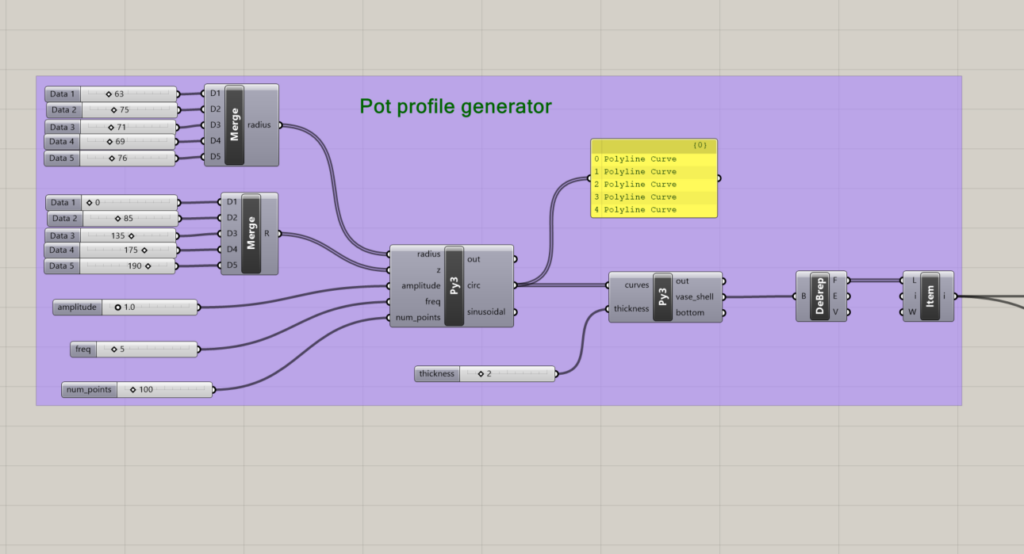

The computational design began with a modified Python script from the vessels assignment to generate the basic shapes of the pots. The script allowed me to create the pot profiles with adjustable parameters such as height and diameter at different levels. Initially, I attempted to generate the Voronoi patterns directly using Python. I wrote a script that used the numpy, scipy, and matplotlib libraries to create a Voronoi tessellation within a defined boundary. The script works fine and generates visual representations of the pattern, with points and edges constrained to the boundary.

While the script produced the desired Voronoi patterns, I had quite a bit of trouble trying to use the script in Grasshopper, as I could not directly import it there. Specifically, I was unable to integrate the Python libraries needed for my initial script. As a result I switched to using Grasshopper built in tools for generating and manipulating Voronoi patterns.

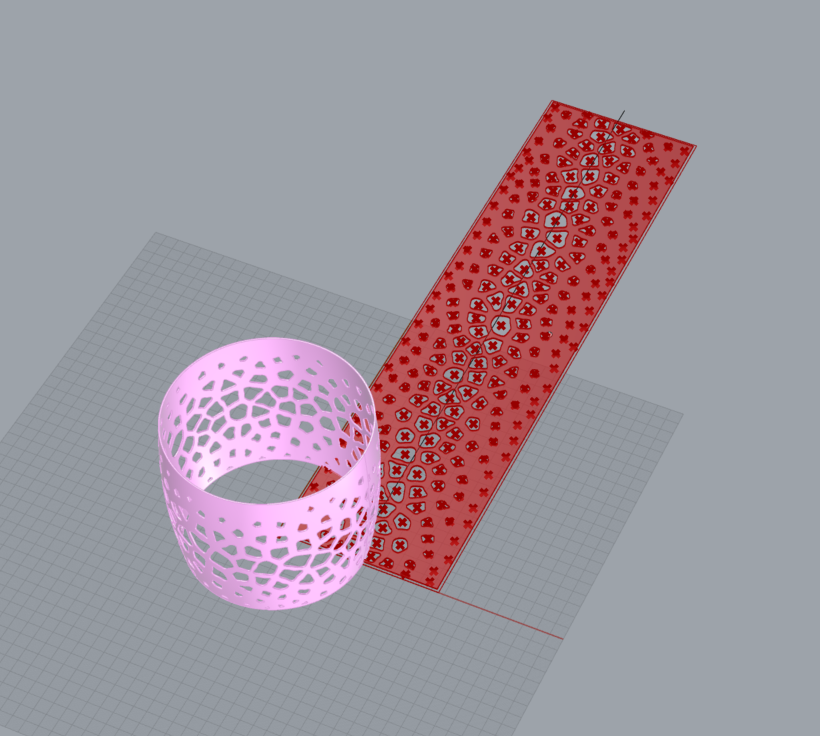

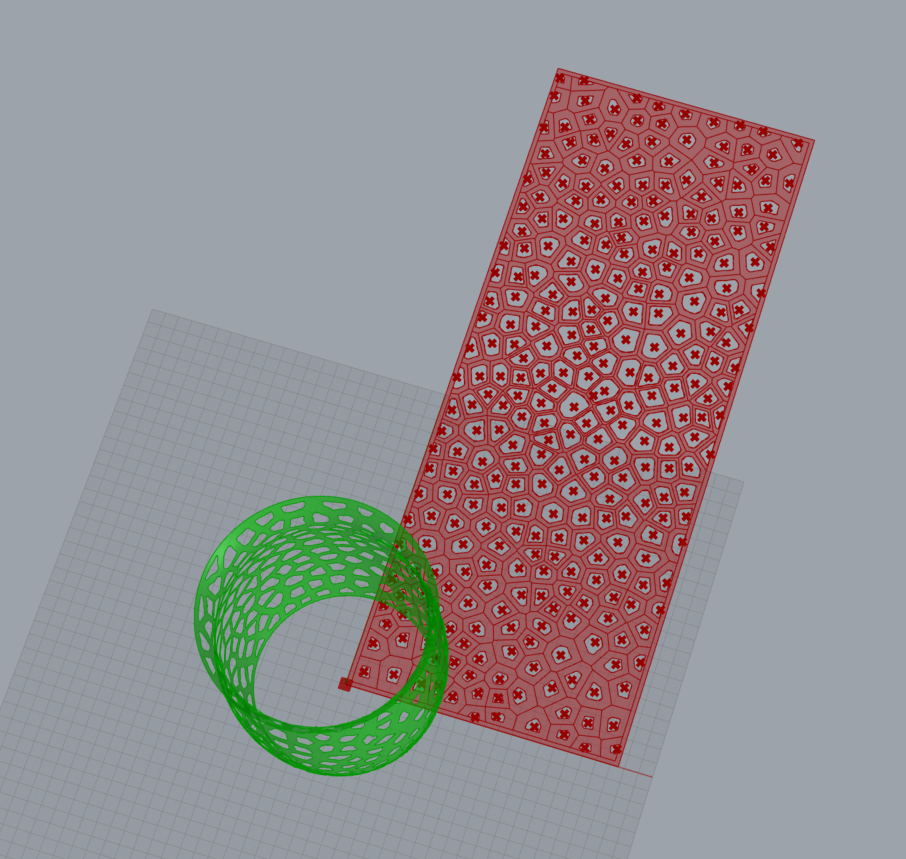

Using Grasshopper, I implemented the Voronoi pattern with a combination of elements. I extracted a rectangular surface area from the pot walls to define the region where the Voronoi pattern would be applied.

To generate the Voronoi pattern, I used a combination of the following Grasshopper elements:

- A populate 2D element to distribute points randomly across the designated area.

- A Voronoi element to create cells based on these points.

- Sliders for fine tuning: Seed slider to control the randomness of the Voronoi pattern, offset slider to adjust the size of the Voronoi Cells.

- Attractor point and curve: Used to vary the cell sizes, making cells near the attractor large and those farther away smaller.

Finally, I used the surface morph element to morph the patterned surface onto the cylindrical pot wall. The resulting model was then baked into Rhino and exported as an STL file for 3D printing.

Fabrication

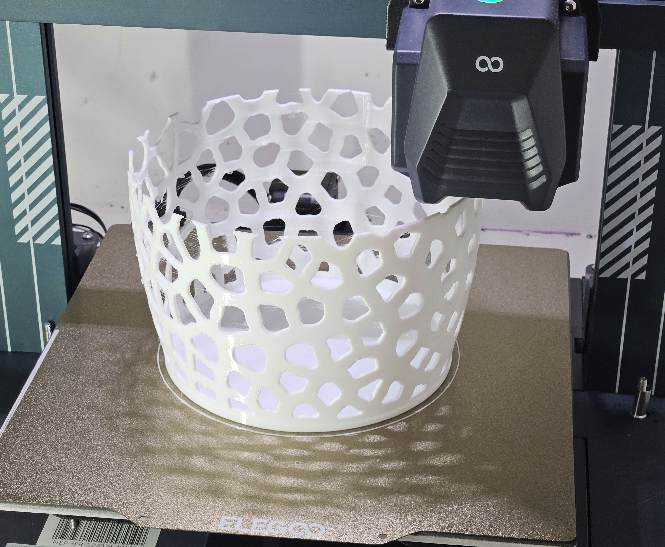

The pots were fabricated using TPU filament on my 3D printer. TPU was chosen for its flexibility, which prevents damage to the delicate roots of my orchids during repotting. The fabrication process involved:

- 3D Printing Setup: The STL files were imported into Cura slicer, where I made several adjustments to the print settings to minimize the need of supports, and the amount of printed defects. I adjusted the print speed, retraction rate, flow rate, print bed and extruder temperature for the best results. I based my adjustments on test prints I made, and by reading online resources for settings of the same model as my 3D printer (Elegoo Neptune 3 pro).

- Challenges: The flexible nature of the TPU filament, along with the higher print temperature required, caused minor defects on the printed objects. I observed an increased occurrence of “stringing” as compared to PLA filament. Additionally, the taller prints had increased defects such as “globs” and other imperfections on the higher layers. The defects were mitigated by tweaking the printer settings in Cura and by doing minor defect corrections by hand.

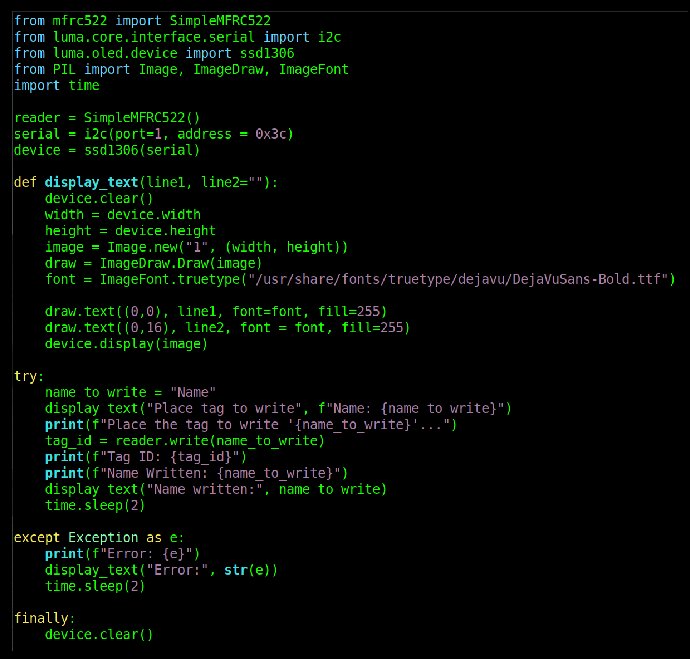

RFID Integration

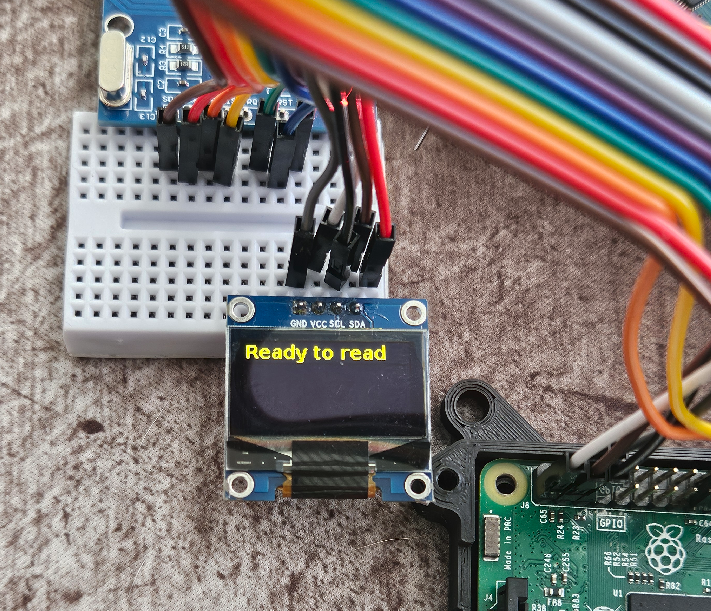

The RFID tracking system was implemented using a Raspberry Pi 3B and an RC522 reader module. Additionally, I integrated a 128×64 pixel OLED display module for real time indication. Each pot was assigned a unique RFID tag, and the system logs watering events by recording the timestamp, tag ID, and pot name in a CSV file.

The process involved:

- Configuring the RC522 module to communicate with the Raspberry Pi via serial peripheral interface (SPI).

- Writing Python scripts to: Read RFID tag IDs’. Write to the RFID tags (to assign a name). Log the scanned data with ID, timestamps and given names into a CSV file. An additional shell script to auto-initialize the RFID scanner on boot-up.

- Testing the system to ensure consistent tag detection and data logging.

This integration complements the 3D-printed pots by providing a digital layer of functionality, turning them into smart plant care tools.

Outcome

Results of 3D-Printed Pots

The final 3D-Printed pots successfully achieved my intended goals of incorporating Voronoi patterns, and using flexible TPU filament. The Voronoi pattern walls create large holes that are assumed to enhance airflow around plant roots, which is essential for orchids. While the pots have not yet been tested with orchids, the perforated design allows for enough air circulation and drainage.

For presentation purposes, I will be filling them with lightweight expanded clay aggregate (LECA) media, which is a commonly used substrate to accommodate orchids. The lightweight nature of TPU pots makes them easy to handle compared to traditional clay or ceramic pots, and their flexibility ensures they are not susceptible to breaking if dropped. However, care should still be taken to protect plants during use.

- Material Properties: TPU filament provides a combination of flexibility and durability. Reducing the risk of damaging from accidental drops.

- Aesthetic and Practical Design: The Voronoi patterns enhance visual appeal while maintaining structural integrity for plant support.

- Lightweight: The pots are significantly lighter than traditional alternatives, making them suitable for indoor use.

Performance of the RFID System

The RFID tracking system was tested and demonstrated reliable performance in logging watering events. Each pot’s unique RFID tag was read accurately by the raspberry Pi based system, and data was saved into a CSV file, capturing tag IDs, timestamps, and assigned names. The OLED display provided real-time feedback during testing, enhancing usability.

- Functionality: the system supports automated tracking of watering schedules, making it a practical addition to the 3D-printed pots.

- Flexibility: It allows for assigning custom names to pots, which could be useful for managing a large collection of plants.

- Scalability: The system can be expanded to include additional pots or integrated with external tools like Google Calendar for scheduling.

Future Work

While the current project demonstrates the successful application of computational design and digital fabrication, several areas for improvement and expansion remain:

- Integration with External Systems: Future iterations could include integrating the RFID tracking system with digital platforms such as Google Calendar or custom plant care apps. This would allow for automated scheduling of watering reminders or other maintenance tasks based on the logged data.

- Expanded testing: After the presentation, I am planning to actually repot some of my orchids into the 3D-printed pots. This will allow for practical testing of their performance, including airflow, root health, and overall suitability for Phalaenopsis orchids, which are the species of orchids in my possession.

- Testing different hardware: I would like to get my hands on a more compact, powerful microcontroller for testing. My current Raspberry Pi, though relatively small, is still rather cumbersome for what I had in mind. I originally wanted to use an arduino Nano but that didn’t work out. I will try to get a ESP32 board or a Raspberry Pi Pico for future testing.

- Appropriate system case: I unfortunately ran out of time to design and test a case system for the RFID reader module and display. I am going to be using them on a small breadboard. This is functional but not very elegant. I will eventually create a nice case for the system.

- Design optimization: Additional iterations of the pot designs could refine the Voronoi patterns, adjusting the cell size and distribution to find an ideal size of the perforations. I ordered the LECA substrate after I had printed the pots, and it turned out that some of the holes are too large for the substrate.

- Increased Durability: Exploring other filaments or material blends might improve my designs. I want to eventually print some of my designs using PLA filament to compare the performance and durability between TPU and PLA.

- Scaling the System: The RFID tracking system could be expanded to support a large collection of plants or adapted for other applications, such as tracking growth or environmental conditions using additional sensors like temperature or moisture.

- Broadening Applications: The Voronoi pattern design and RFID tracking system could be adapted to other plant care contexts, such as vertical gardens or larger plants using 3D-printed modular moss poles or other structures. These applications could address different plant species’ specific needs.

Reflection

This project has been a fun and valuable learning experience, allowing me to combine existing skills with new digital fabrication skills learned in this course. Working with Grasshopper expanded my understanding of parametric modeling and provided a fresh perspective on computer-aided design. Additionally, integrating the RFID tracking system gave me the opportunity to revisit skills from my previous interest in small electronics, PLC programming, and IoT devices.

One of the main challenges I faced was adapting my initial approach for generating Voronoi patterns in Python to integrate with Grasshopper and Rhino. This shift improved my workflow and highlighted the importance of selecting the right tools for different stages of the design process. Similarly, experimenting with TPU filament, a material I was not familiar with, required troubleshooting its quirks, which led me to discover many advanced printer settings I hadn’t explored before.

This course has transformed my perception of 3D printing and design from being purely utilitarian tools to versatile mediums with a broad range of applications. I now see them as not only functional but also creative tools that can be used for artistic expression and innovation. I am particularly intrigued by the potential of experimenting with alternative materials like glass, clay, or unconventional options like coffee grounds and ground leaves. The combination of computational design and digital fabrication has shown me how technology can merge creativity with practicality, opening doors to innovative and creative projects.

Through this experience, I’ve gained not only technical skills but also a deeper appreciation for the creative potential of 3D printing and design. I look forward to applying these skills to future projects, whether it’s scaling up designs, exploring new materials, or continuing to expand IoT integrations to include more sensors and automation. This project has really widened my understanding of what is possible in computational fabrication and design.

References

- A. Lazar, Emanuel, H. Rycrofr, Chris, Lu, Jiayin (2022). “Voronoi Cell Analysis: The shapes of particle systems.” Am. J. Phys. 90, 469–480 (2022). Available at https://pubs.aip.org/aapt/ajp/article/90/6/469/2820132/Voronoi-cell-analysis-The-shapes-of-particle.

- Hudson, S. E., Hammer, J., Williams, K. (2021). “An Upcycled IoT: Building tomorrow’s IoT out of today’s household possessions.” XRDS, Summer 2021. Available at https://dl.acm.org/doi/10.1145/3466872.

- Last Minute Engineers. (n.d.). “In-Depth: What is RFID? How it Works? Interface RC522 with Arduino.” Available at https://lastminuteengineers.com/how-rfid-works-rc522-arduino-tutorial/.

- The Different Design. “Grasshopper Voronoi Tutorial (Easy)”. YouTube, uploaded by The Different Design, Dec. 3, 2020. Available at https://www.youtube.com/watch?v=T4HRsC_YWvM.