Introduction

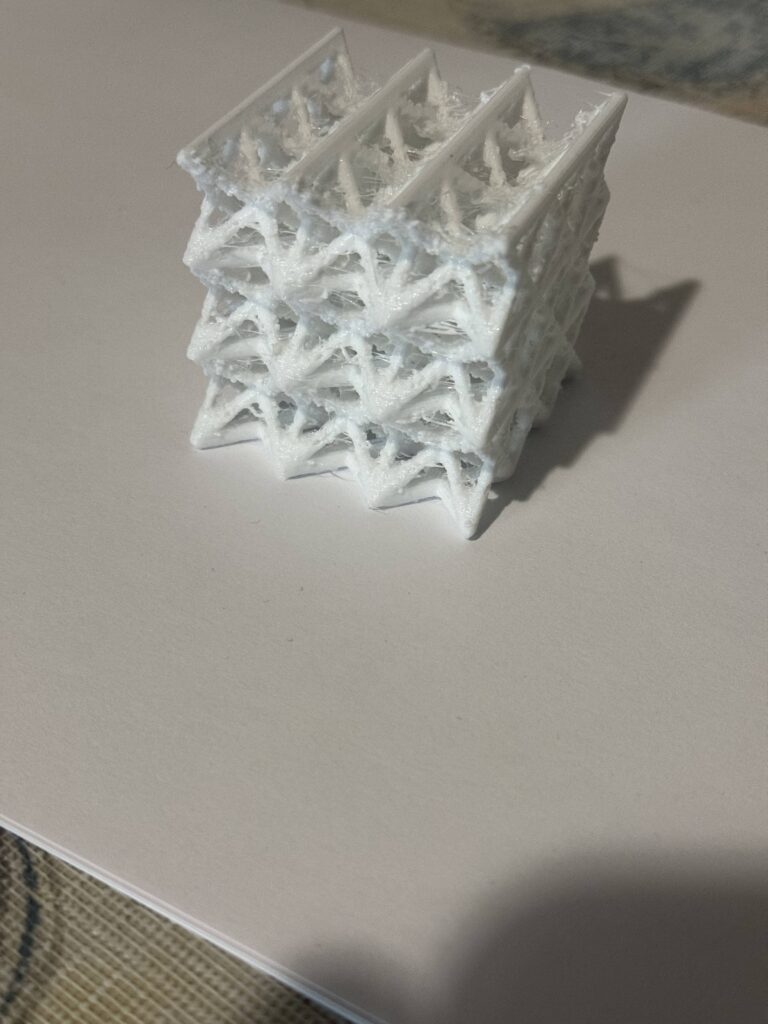

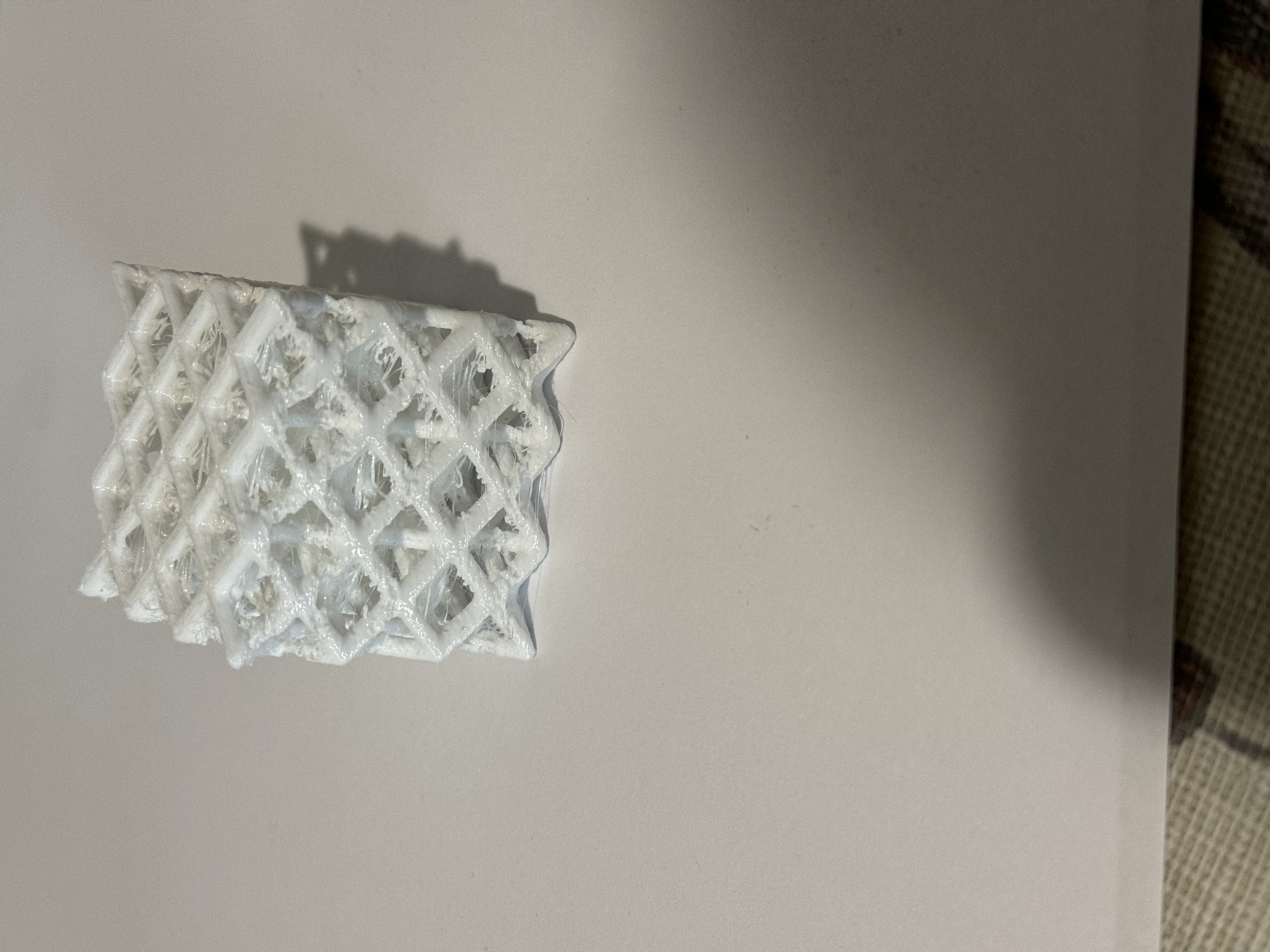

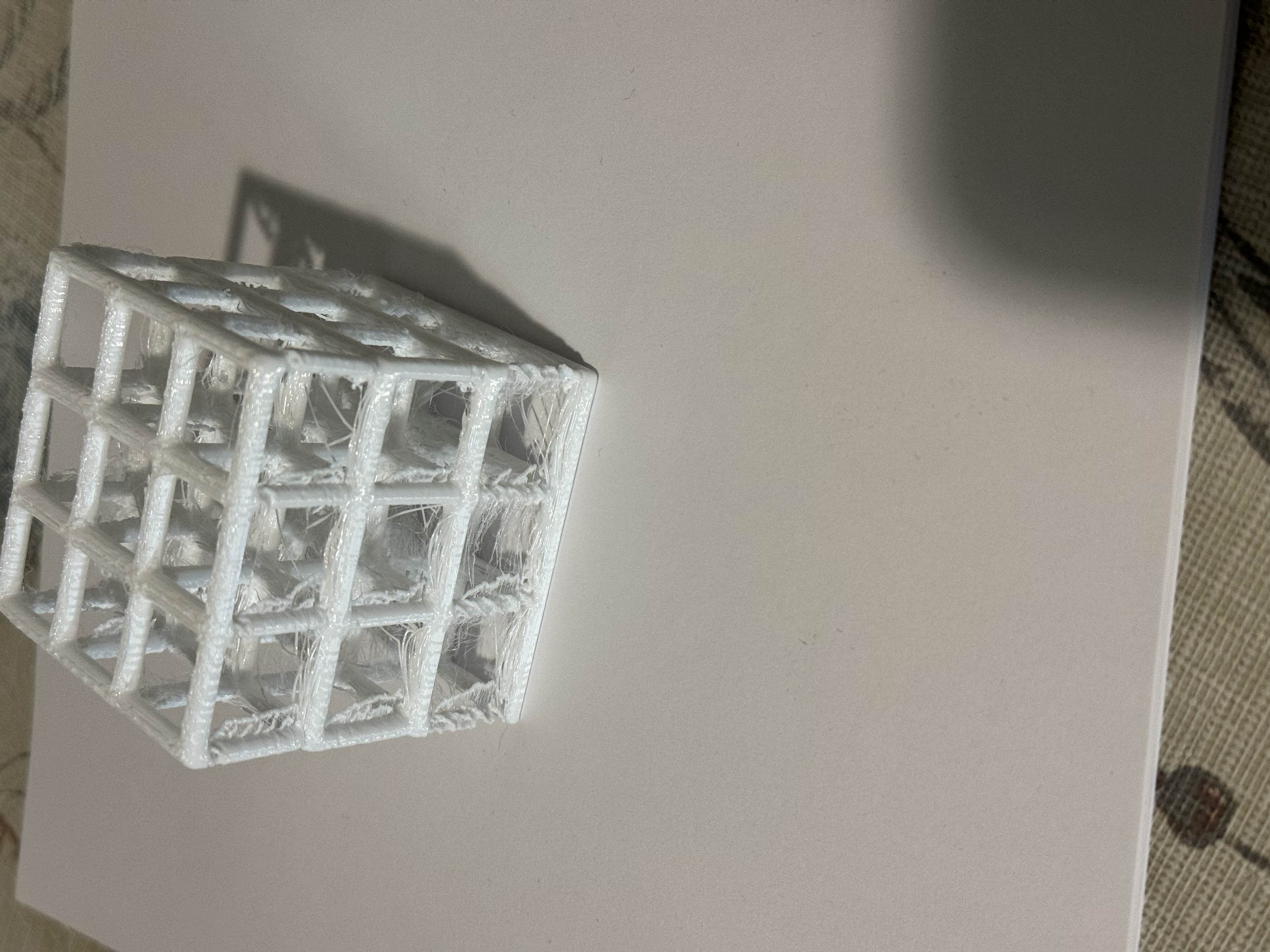

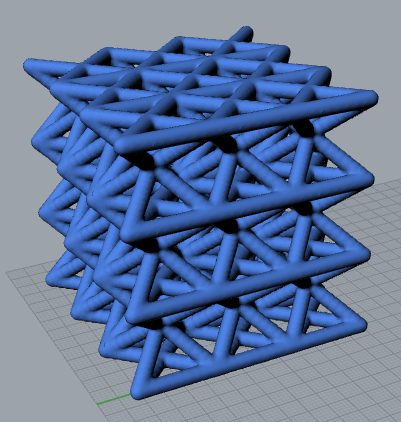

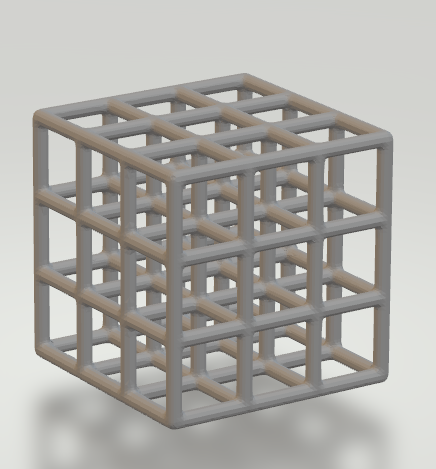

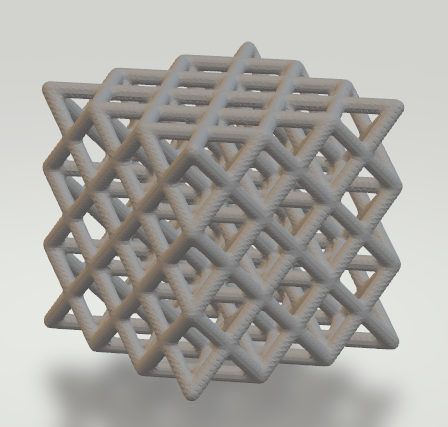

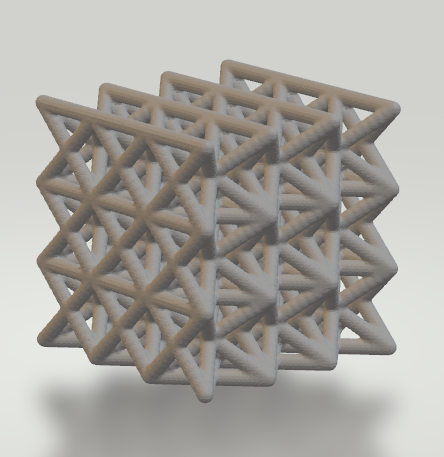

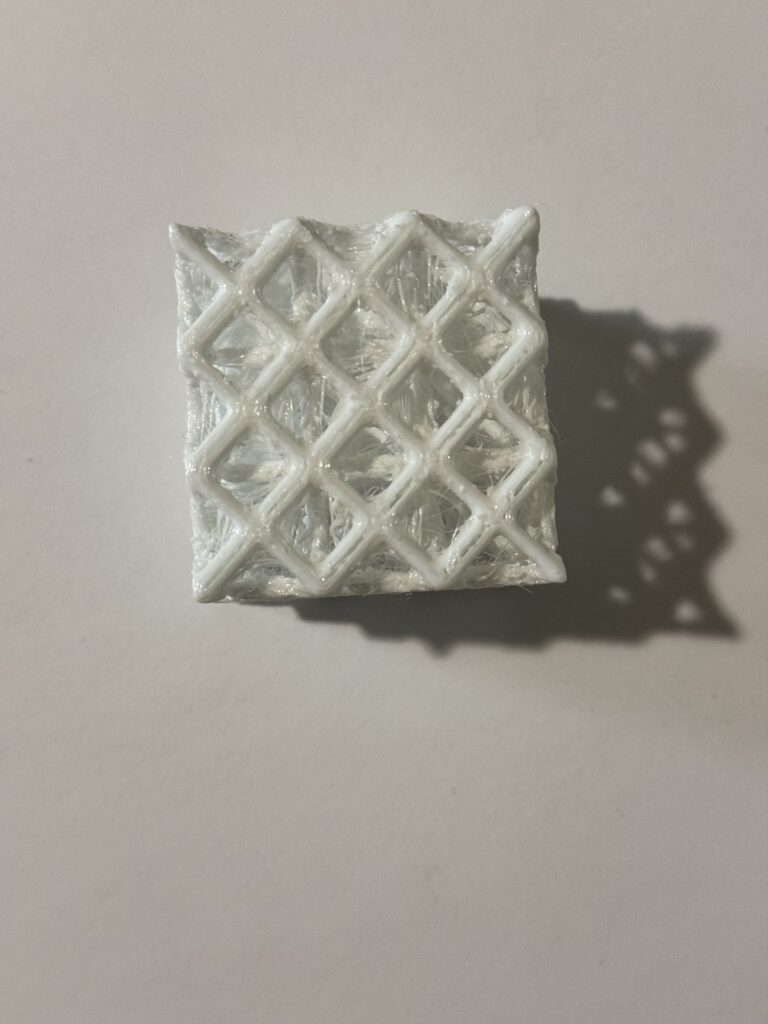

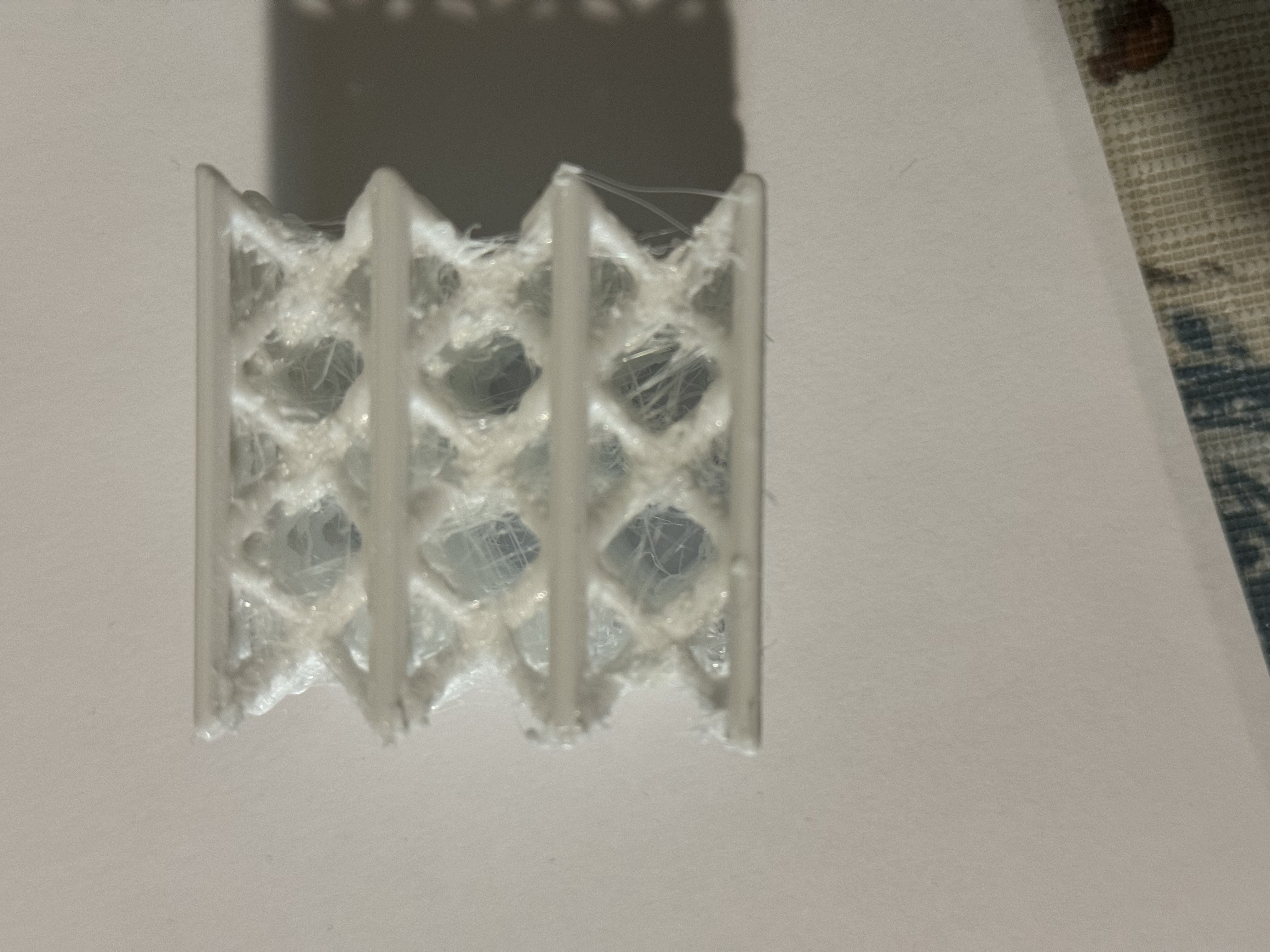

I was interested to create lattice structures from projects at work. I wanted to create various lattice structures that took the overall shape of a cube. I was able to create a basic cubic lattice pattern, a diamond lattice pattern, and a triangular lattice pattern. I discovered grasshopper plugins that help use my programs to volumize the lattice structure.

Background Research

A lot of my inspiration of creating lattice structures came from some of the 3D printing stuff I do at my internship. I have printed models of certain projects with the infill being a lattice structure to save resin. After doing some research I found an academic article that describes a process of 3D printing lattice structures using an SMP filament, that demonstrates the shape memory of the filament. Here is the article the describes using the SMP filament with lattice structures. https://link.springer.com/article/10.1557/s43578-021-00225-2. Using this research I tried to find places to be able to purchase some of this filament but the only place is in China. I decided to contact a local 3D printing company called Roadrunner 3D and they gave me a lot of information about TPU material and creating lattice structures using it.

Process: Creating the Designs

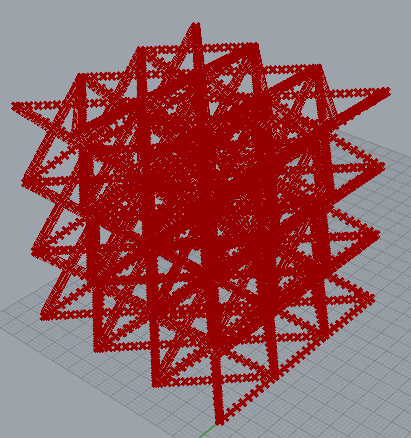

My process with creating the design of the lattice structures was pretty straight forward. I created the designs to fill in a cube mesh shape. Using the mesh, I populated the cube with points and connected lines in various patterns through the points and the edges of the mesh. To create different lattice structures I changed the way the lattice lines were connected through various functions. Using the mesh and the joined lines, I created a bounding box of the lines and mapped it to a Box-Array node in grass hopper that creates an array of the box of various sizes. For my project I just create a 3x3x3 array of the boxes. The result of Box-Array node is a geometry of the lattice structure with the lines. I then used the divideCurve node to create points of the lines. At this time, I ran into a challenge of actually creating a volume to print of the lattice structure. I then found a grasshopper plug-in called Dendro that helps volumize a geometry.

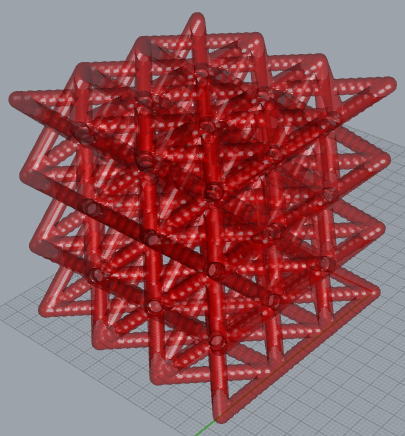

Here is a image of the final lattice structure before

using the Dendro plugins and its functions. Using

the points list, I had to create a range of the points

which is (n-1) points, where n is the number of

points.

I then use a node called Volumize Points witch

take the divided curve of points and add a volume

to it and creates the actual structure of the lattice.

Using the new volume geometry, I use another

node called Volume Smooth that smooths out

the geometry and then finalize the structure with

another node called Volume Mesh, that creates a

mesh of the volume.

Dendro Plugin

Points to Volume: Create a volume from a point set.

– Points as a List

– Points Radius as a List

– Settings

Smooth Volume: Apply smoothing to volume.

– Volume

Volume to Mesh: Create a mesh that approximates volume geometry.

– Volume

– Settings

Settings: These are the settings for managing the size and adaptivity of the volume that is generated.

Documentation of Dendro: https://grasshopperdocs.com/addons/dendro.html

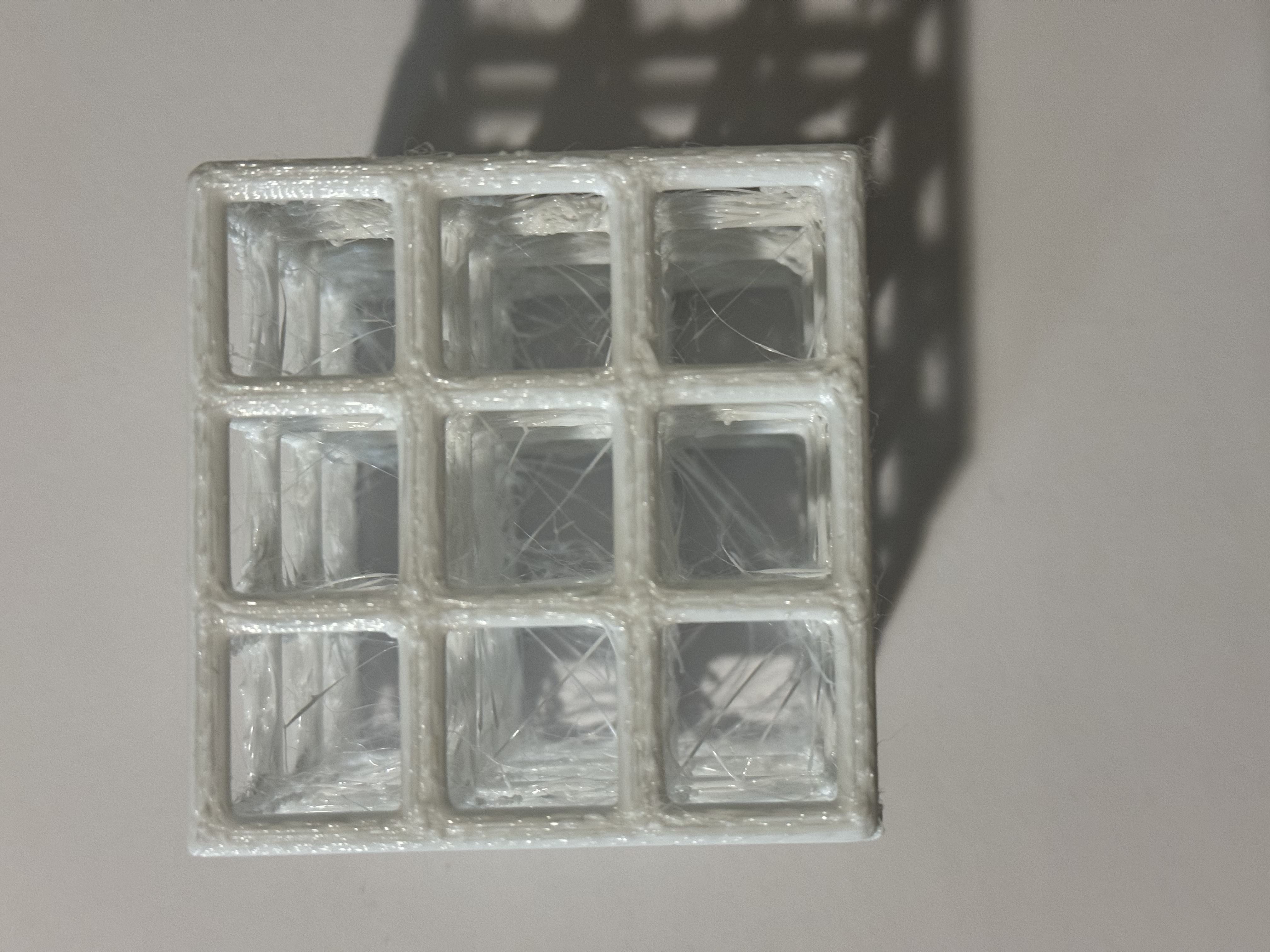

Process: Printing using Bamboo TPU

With using TPU came a lot of challenges. At first I had to change the material type in cura when slicing the .stl file. Another challenge I had with this material was finding a good printing speed for the material to have it not really stringy. I had done some research and found the best speed was 30 mm/s. I had adjusted these settings inside of cura and my prints started to come out great.

Outcome

Future Work

In the future, I would create a program that would take these lattice structures and implement to different objects. For example, I would take the lattice structure of the 2nd design and use that to fill in a sphere object or anything else. If I had extra time, I was planning on doing this.

Reflection

This project has showed me how much you can do with grasshopper plugins. I also learned how to create lattice structures and learned how to implement them into shapes. I plan on using these new techniques with future projects at work. Since we use a resin printer, having the inside of the model be a lattice structure, I could save a lot of time printing and a lot of actual resin.