Progress

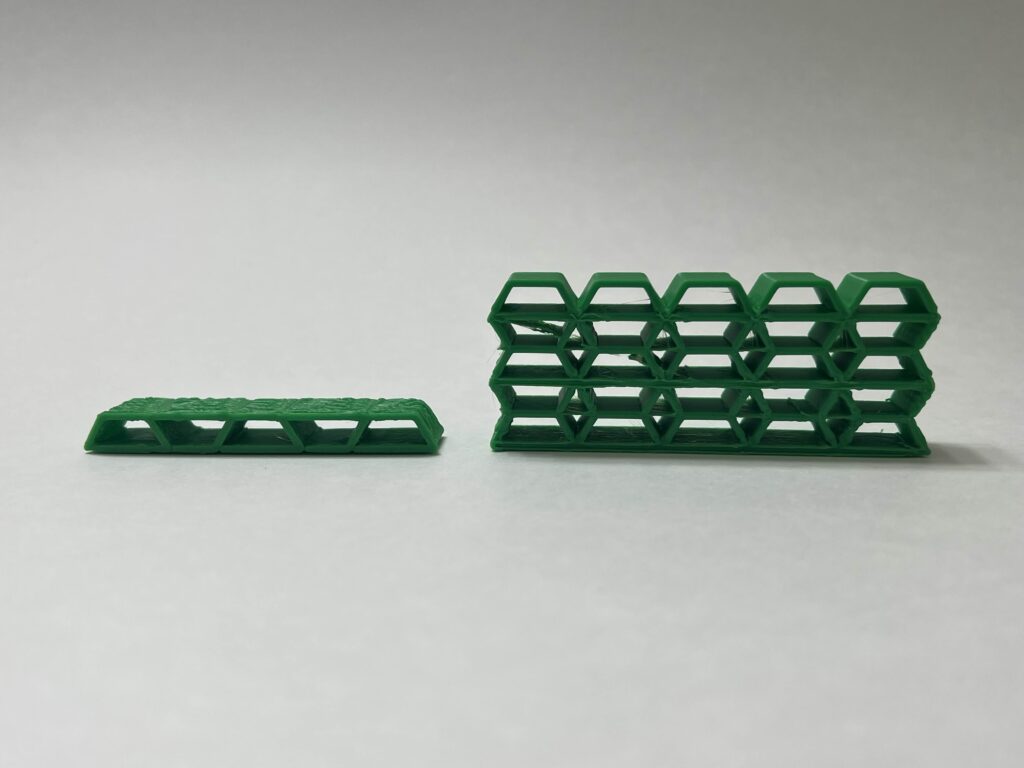

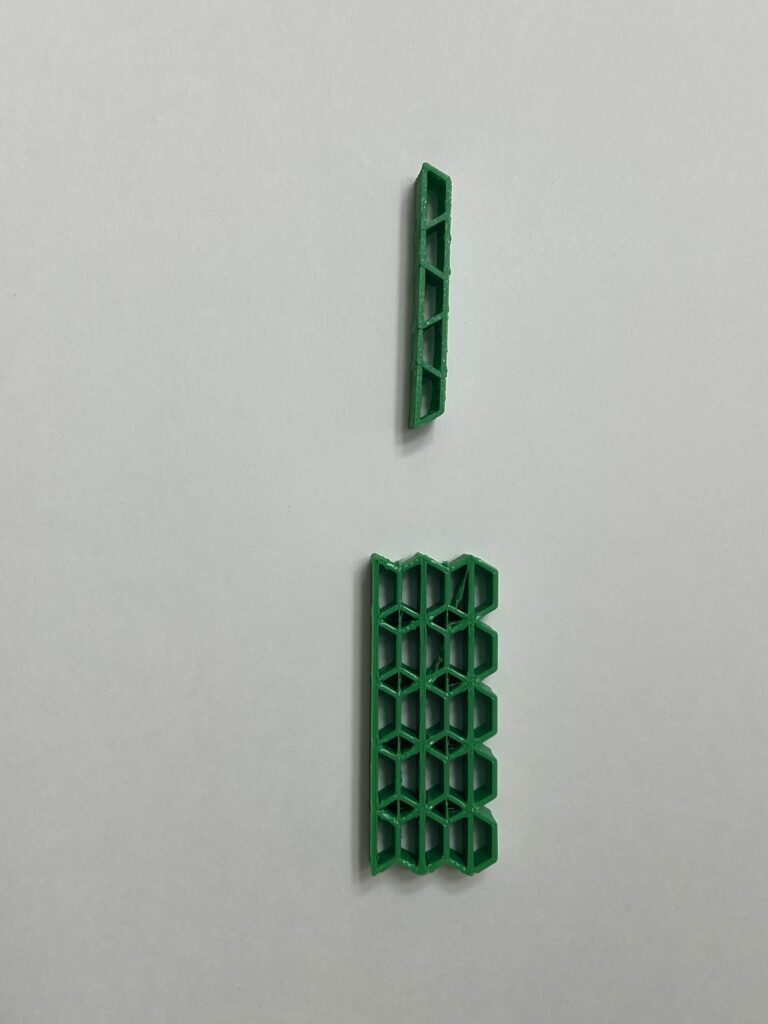

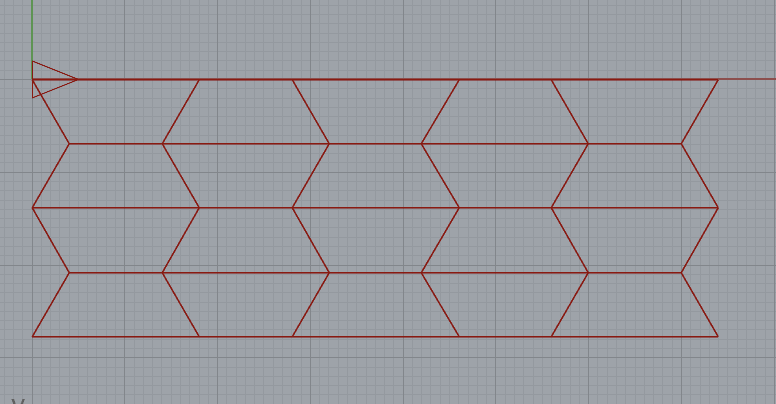

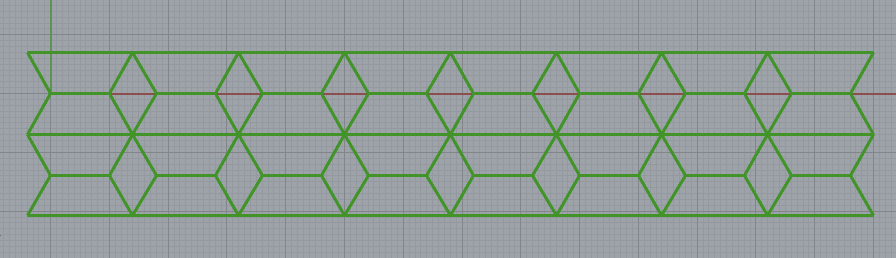

Through some continued research on structural patterns and based on the example of our initial proposal, we have designed two trapezoid-based infill patterns on the XY-plane. One pattern approaches redecing filament waste by introducing gaps between each trapezoid row, however the structural quality from this approach has yet to be evaluated. The second pattern aims to improve the integrity of the first pattern by reducing gaps, at the cost of increased filament.

Currently, the patterns are generated using ExtruderTurtle, which will in future steps allow for exploring path optimization of the nozzle (this has not been looked at in the current progess). Currently, we are trying to reproduce the same pattern in grasshopper / rhino, which will let us slice the design in CURA for comparison with our raw GCODE approaches.

Timeline

- November 26th – December 6th:

- Generate the infill pattern inside the bounds of a rectangular shape

- Explore potential for path optimization of the infill pattern to decrease the print time. An initial idea involves creating a graph representation of nodes and weighted edges for ExtruderTurtle to follow.

- December 6th – 9th: Perform an analysis on the structural quality, filament use, and print time compared to existing infill patterns in CURA.

Deliverables

- Two infill patterns, generated with ExtruderTurtle

- Report of quantitative analysis of print speed, density of the object (filament amount) and strength of printed objects compared to existing infill patterns generated with a traditional slicer.