For this project, I read the instructions and saw the word vessel and thought it was an odd word to pick. So I looked up the definitions after assuming we are not making boats… I just went with the definition off google.

“a hollow container, especially one used to hold liquid, such as a bowl or cask.”

So I thought all I had to do was make something that is Parametric and holds water. Gain inspiration for this youtube video How to make a lighter? / Supposedly burns without fuel!. I thought it would be cool to make a hollow container with no center.

This project was a lesson in humidity. I spent 20 hours messing around with Rhino and Grasshopper. I had a dozen or so minor sputters where the solid difference would cause the cpu usage to jump up and it would eat 10GB+ of ram. But I also had 2 times where I did lose all my work when solid difference invented a black hole and took 10GB+ ram and 100s of Giggly bits of swap space. When I try to recover the work it would override the save file and make me start over.

I don’t think I could make traditional means, In both the subtractive and additive processes. To machine this part you would need to make 2 separate sides of the vessel and weld or glue them together like they did in the youtube video. For an additive that’s not 3d printing like poetry it would be very hard and maybe would have to do a pinch pot style. This would not be as accurate on the inside. For this project.. I see this great for rapid prototyping vases and vessels that you would find at homegoods or worldmarket and the like. But as a process I think parametric design as a whole is great, after buying and using my 3d printer a lot more I invested a lot of filament into the gridfinity system by Zack Freedman and they have many parametric dessines to get the most out of your space.

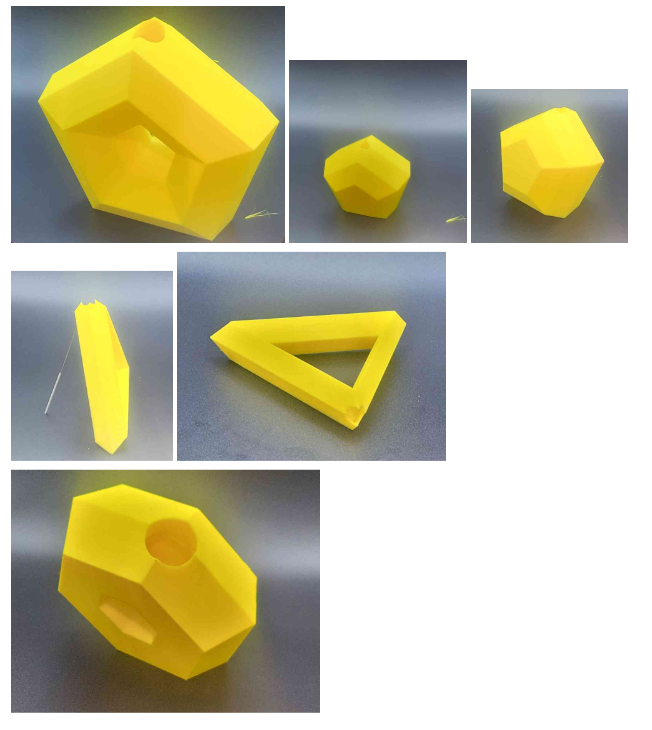

I started out this project wanting to tile my vessel out of hexagons. This would be easy it seems in the C# version where you can look at the class (with reflections) and modify or get the data that way. But In python it seemed that grabbing data out of the class was close to impossible. So I had to change gears and just did it the cs105 way where I built up the shape from scratch with all my own math. You can see remnants of this still in my final version. This is where a bulk of my time went after my second crash I started over and tried to use the built in function and got the vessel built in 1 hour. After trying a lot of things I finished the ring of shape X with the circumference of shape Y. These turned out better than I expected and had very few print issues.

If I was using someone else’s generator of vessels I don’t think I would have any authorship but because I invested so much time (maybe not effort) I feel a deep sense of ownership of every shape it makes. I think that knowing that you could make unlimited “finite” amount of shapes is amazing.

Problems encountered:

Printing problem: I touched my build plate a few to many times and my finger oils got on the plate and nothing would stick to it so I have half a dozen prints that got knocked off in the first 3 min of printing. The spool got snagged and caused the filament to stop feeding causing a back up and I lost 2 prints

Grasshopper problems: Random parameters would cause a nuclear level meltdown. I found this to be the case when I would make my own shapes with loft and 4 x points but when I moved to build functions and polylines it slowed down and stopped happening.

Making of vessels: I was really happy that things were going really well and forgot to document all My parmentors. You can see I gained a new parmenter during this because the hole for the liquid could change sizes. I was surprised I didn’t even think about that when doing the assessment …

Picture during the prints

The current graveyard of failed prints at the bottom of this image

Glam shots:

my grasshopper file

Hi Nicholas, I enjoyed reading about your inspiration for your vessels, and I think the time you spent developing your model was well-spent. It’s an interesting balance to consider how parametric design allows for rapid prototyping, but you may have to spend that extra time figuring out the 3D printing aspect. Do you think your vessels could float if they didn’t have the hole on the sides?

Hello Sachi,

They do float, already and they take alot of force to sink!!! I do agree with you in rapid protyping the amount of time saved finding idea and the printing is constant or worse becuase you might never print ideas that you did not imagine it could come up.

Hey Nicholas,

I think you made a great creative choice in designing vessels without centers. The hexagonal vase in particular is very cool, and I think well worth the effort!

You mentioned the definition of a vase, which got me thinking — will anyone’s vases hold water without leaking? I sort of doubt mine would… Lmk if you find out with yours

Mine hold a shocking amount of water but getting it out is a pain becuase the surface tension. A small smack and most of the water comes, I am hopping that the rest will evaporate.