Current Progress

The first half of this project consisted of a lot of material research followed by process evaluation. Originally we wanted to test each type of material and determine its sound absorption and resonance characteristics, however the equipment we had to test was not precise enough to derive these measurements. We turned to past research on PLA and carbon fiber filament absorption properties (pdfs listed below). We were able to gain proper values for our testing models. Once these values were found, we decided PLA had the more interesting sound characteristics. Carbon fiber had lower sound absorption, but with the time we have left we would like to model PLA first, and if time allows we will test prints in carbon fiber.

After material was determined, we reconfigured our testing process. During our research we found a tool called PachyDerm which is a grasshopper plug in that can model acoustics, however is not compatible with Rhino 8. Luckily there is a python library named Pyroomacoustics and when used with numpy-stl library we can run acoustical simulations on the models we have created.

Our base models have been formed, material determined, and testing method further refined. We now have a proper baseline to begin testing infill patterns within our models to amplify, dampen, and alter sound.

Speaker Housing

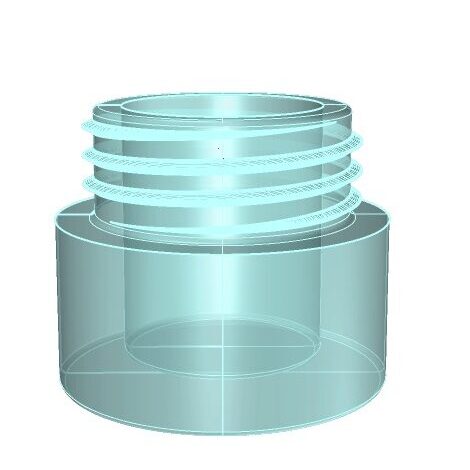

The Acoustic Testing System Base is precisely designed to hold the mini speaker snugly and securely attach to all future vessels, ensuring consistent and accurate testing parameters. It features a 100% infill structure, effectively containing sound within the base. The vessel adapter, pictured below, serves as the foundational design for all future vessels, allowing them to seamlessly connect to the speaker housing. Like the base, the vessel adapter is also constructed with 100% infill for maximum durability and acoustic isolation.

Acoustic Testing System Base

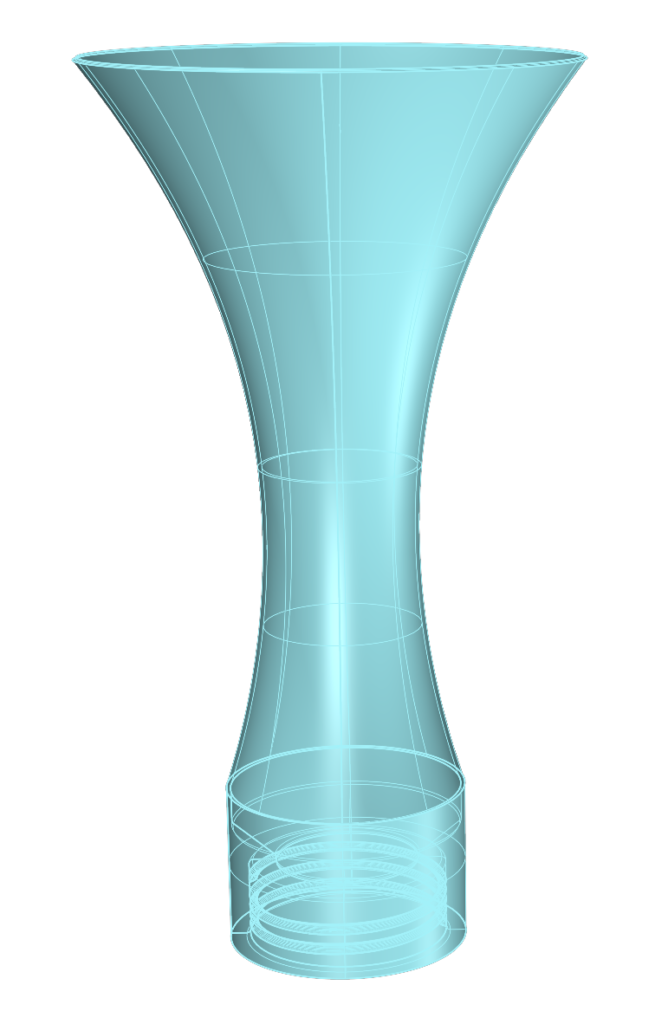

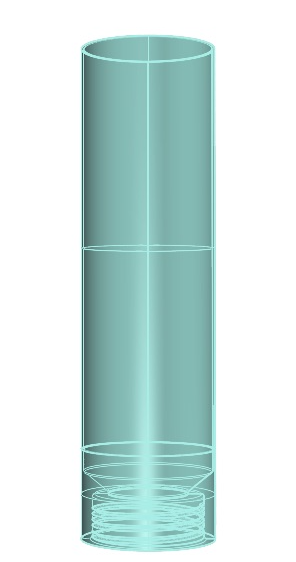

Control Group Vessels

We created two baseline vessels to serve as controls during experimentation. All control vessels will have a height of 250 mm, excluding the vessel adapter. They will also have a 100% infill and a wall thickness of 1 mm. These models will act as the control group for comparing the results of modifications to infill patterns and densities. During testing, the control vessels will provide the base shape and serve as a housing for the experimental infill patterns.

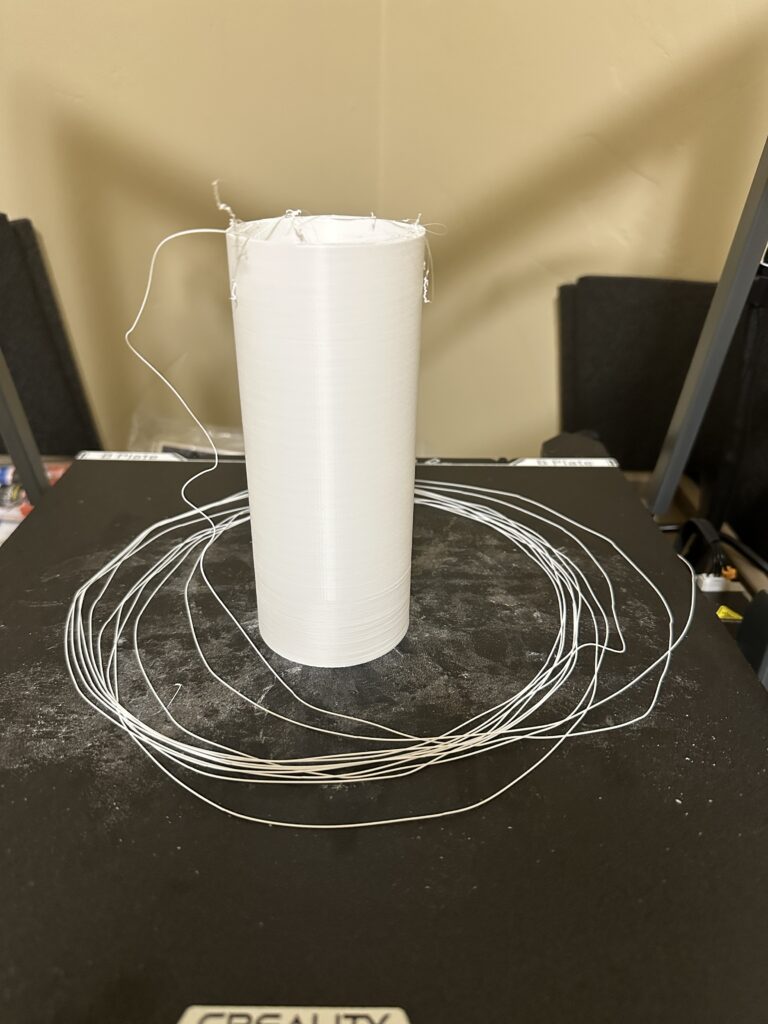

Current Prints

Failed Prints

Updated Timeline

| WEEK | PLAN | STATUS |

| Week 1 : Nov 13-17 | Determine printing filament Design control vessels | Complete |

| Week 2 : Nov 18-24 | Print vessel base Print controls vessels | Partial Complete |

| Week 3 : Nov 25- Dec 1 | Test and alter infill patterns | In progress |

| Week 4 : Dec 2-8 | To do |

Updated Deliverables

- Two control Models

- Vessels intended to amplify sound

- Vessels to mute sound