Design Process

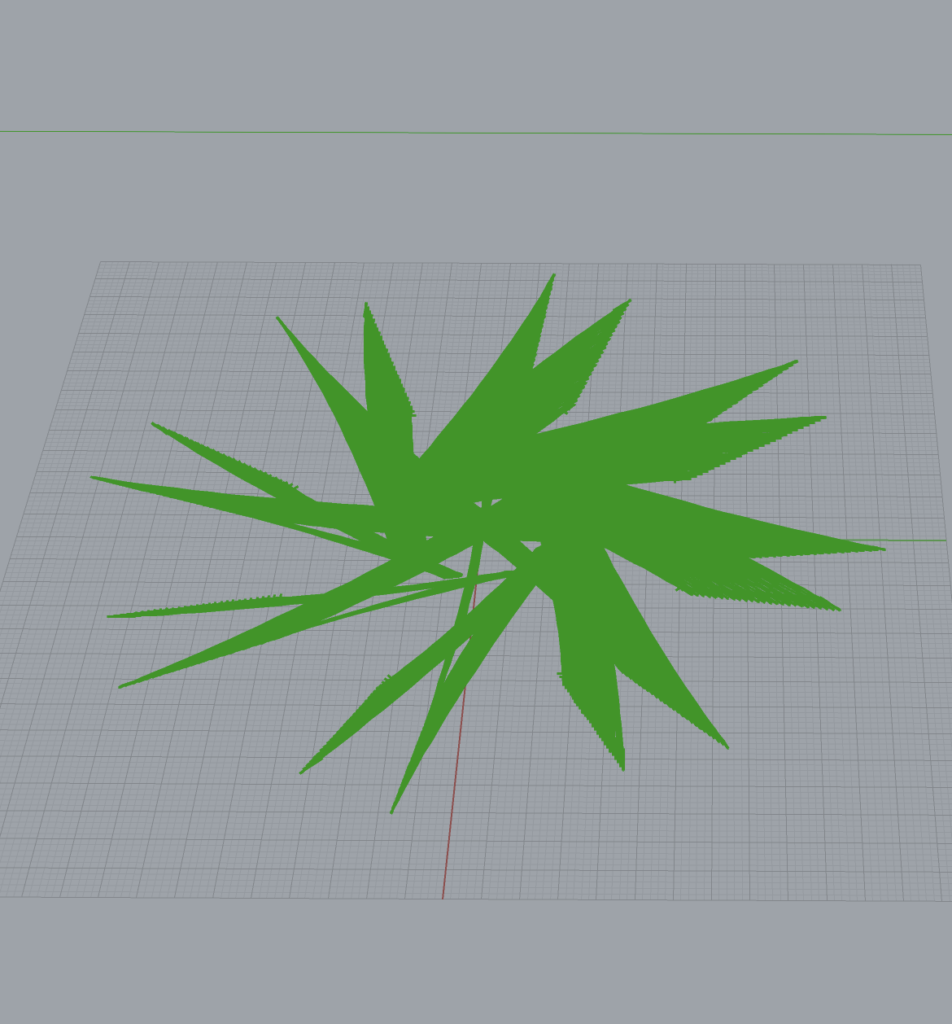

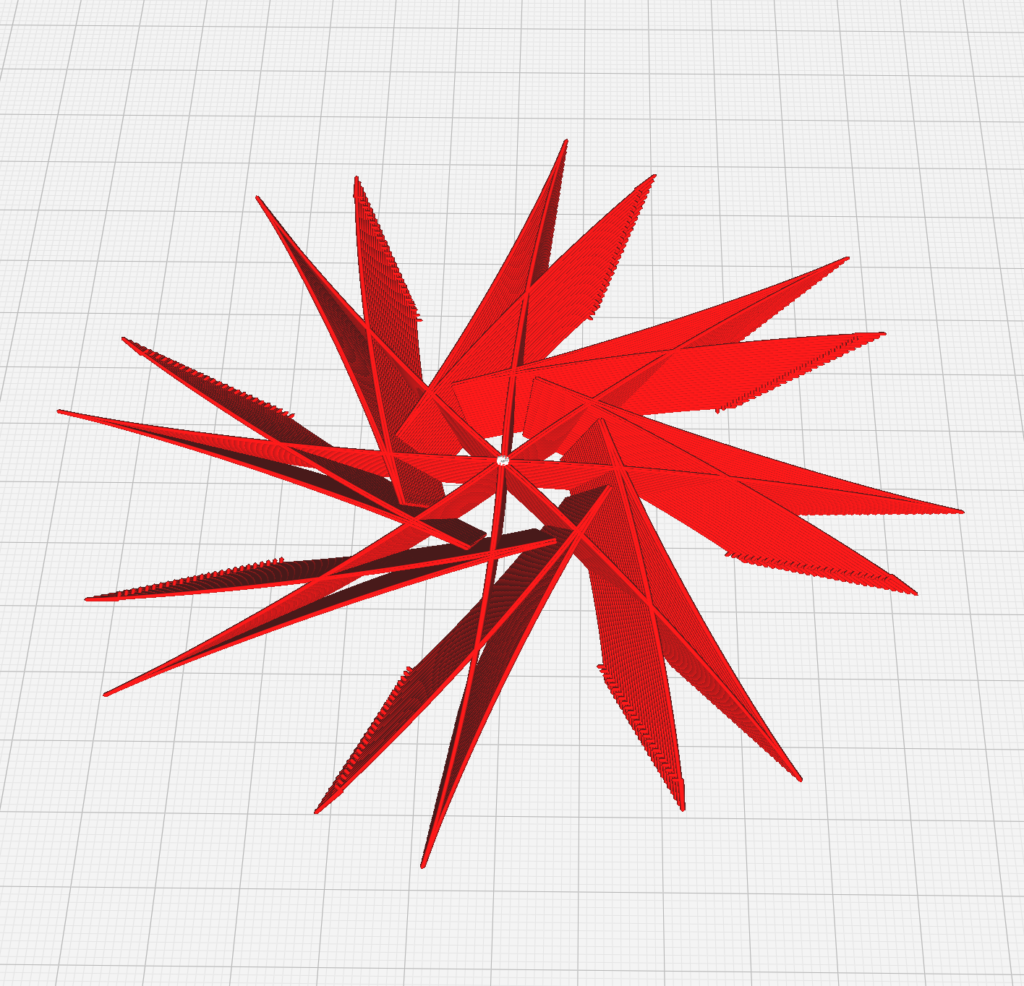

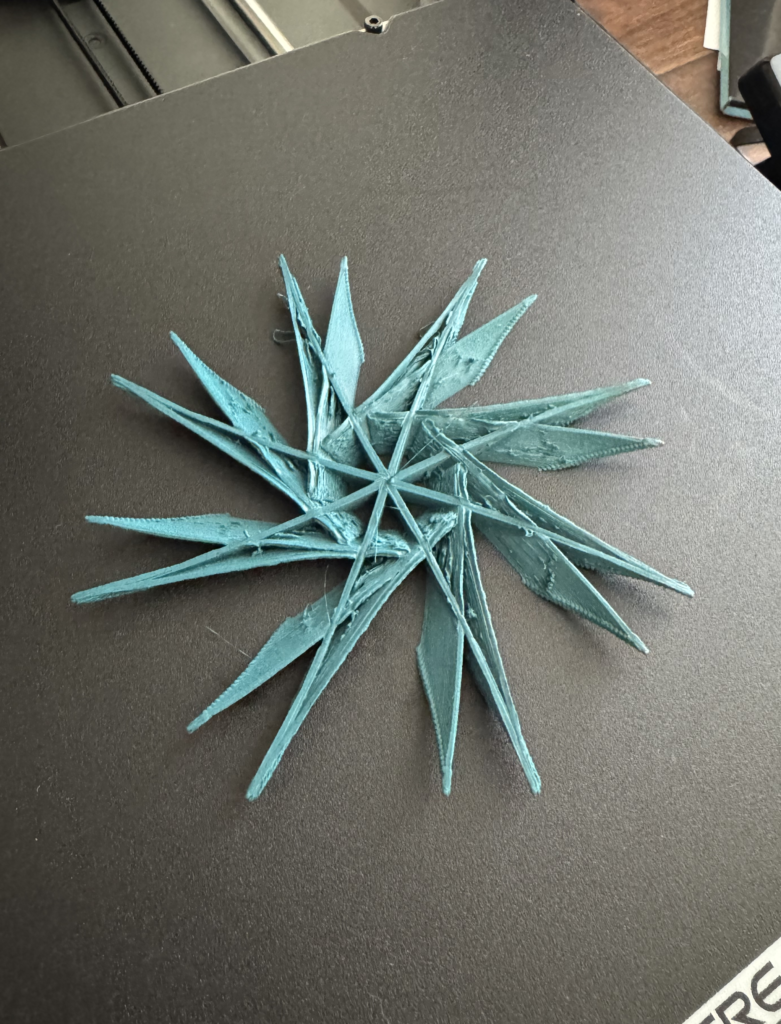

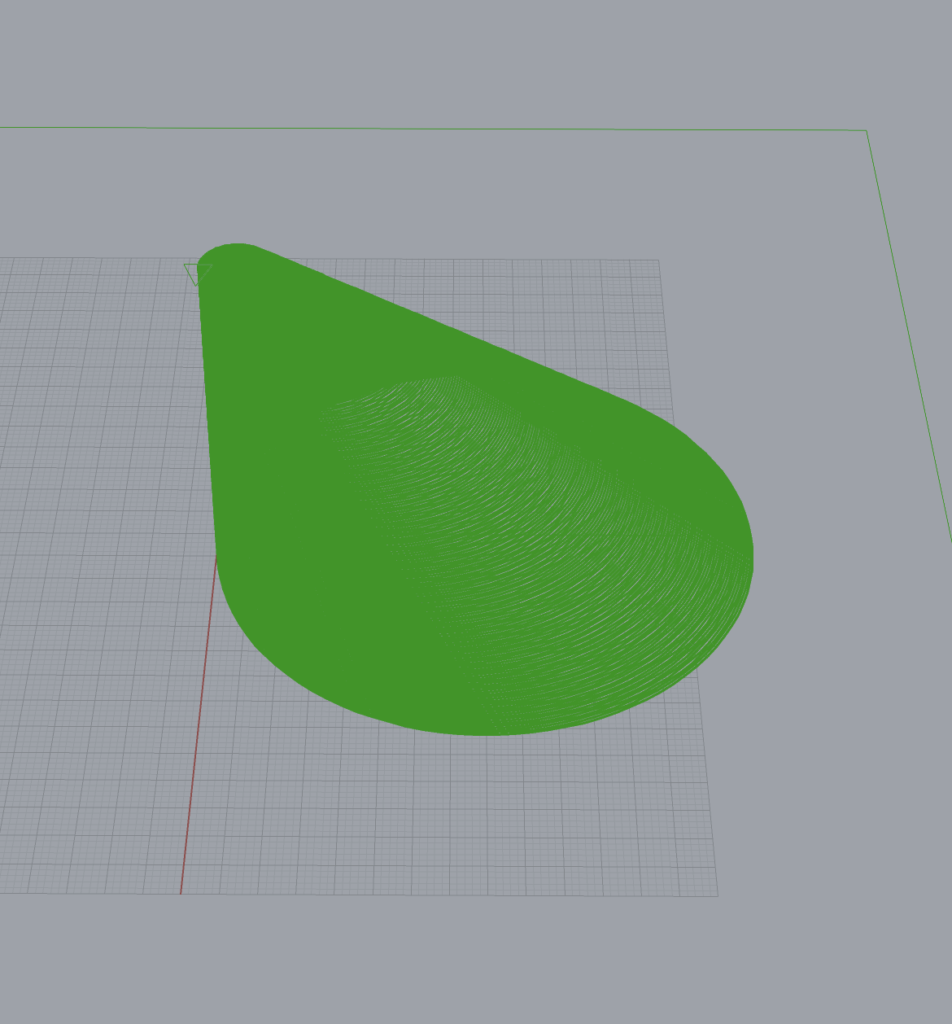

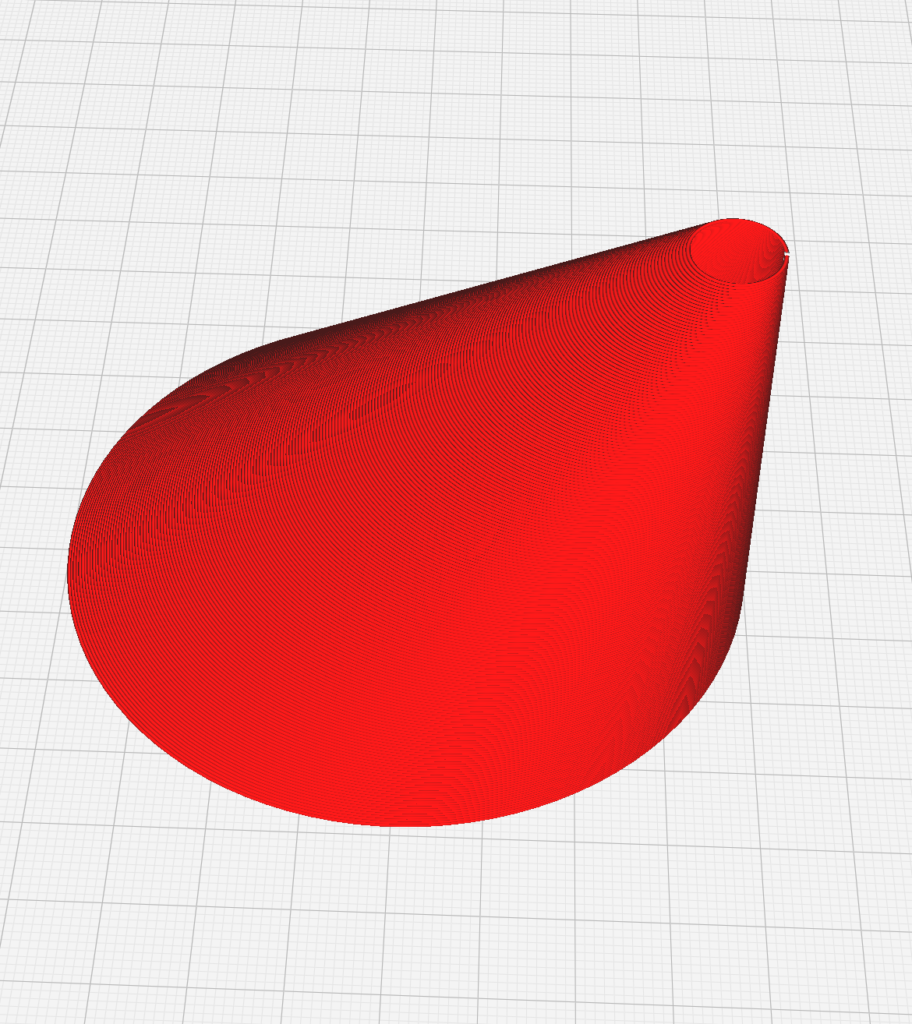

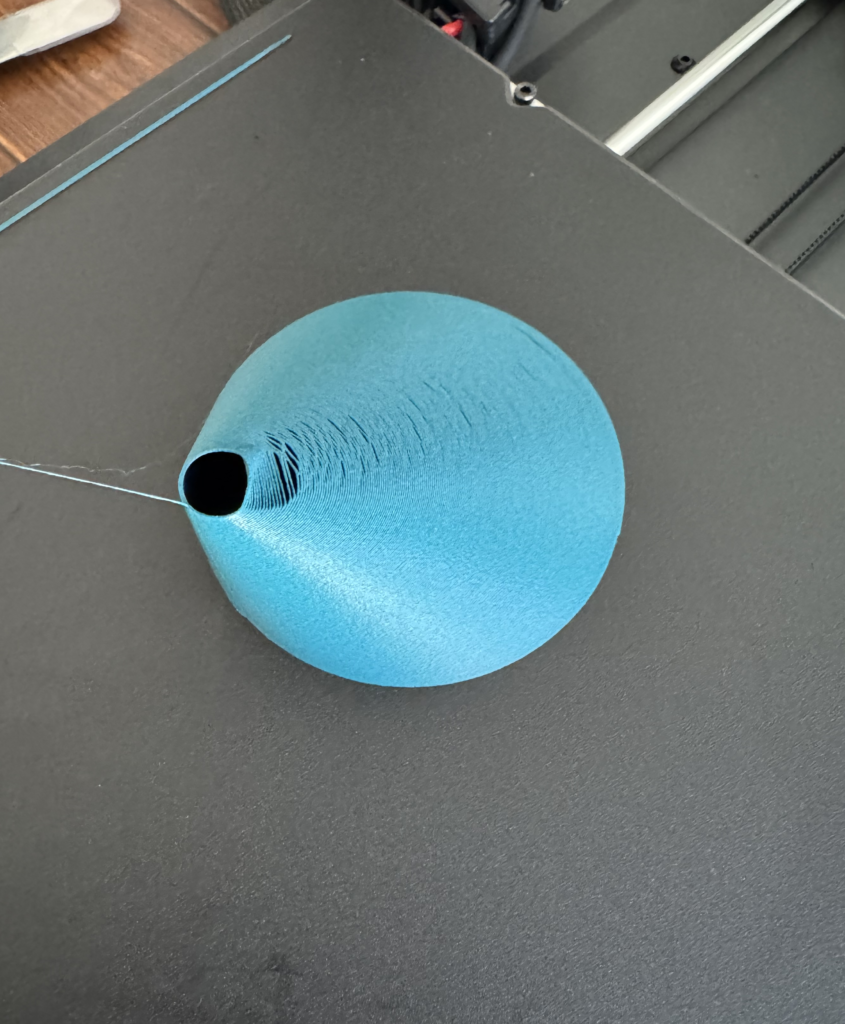

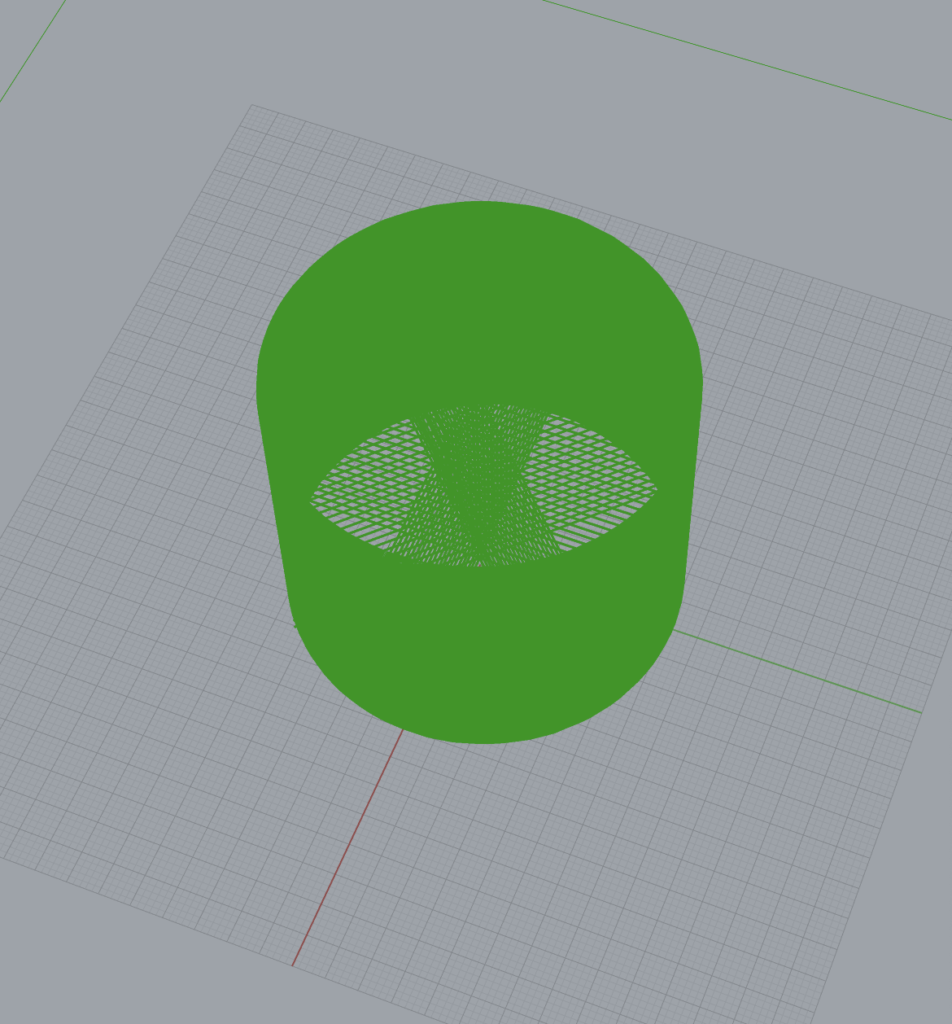

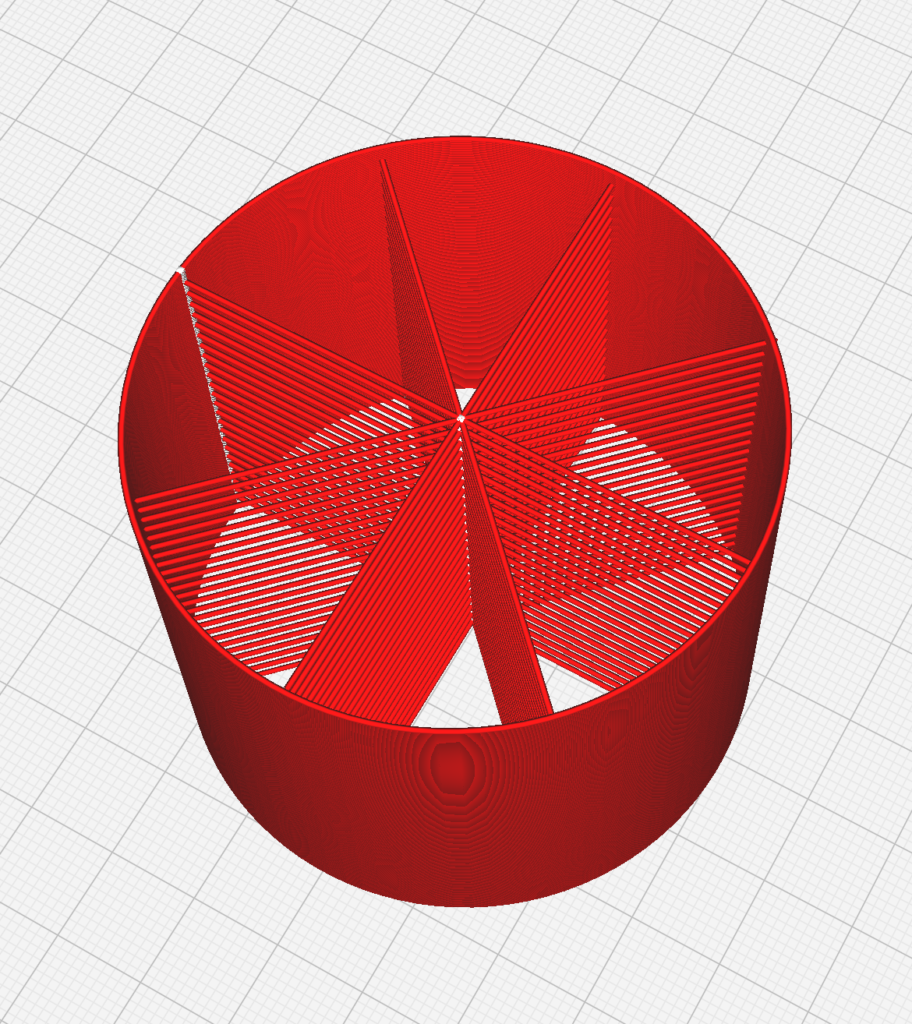

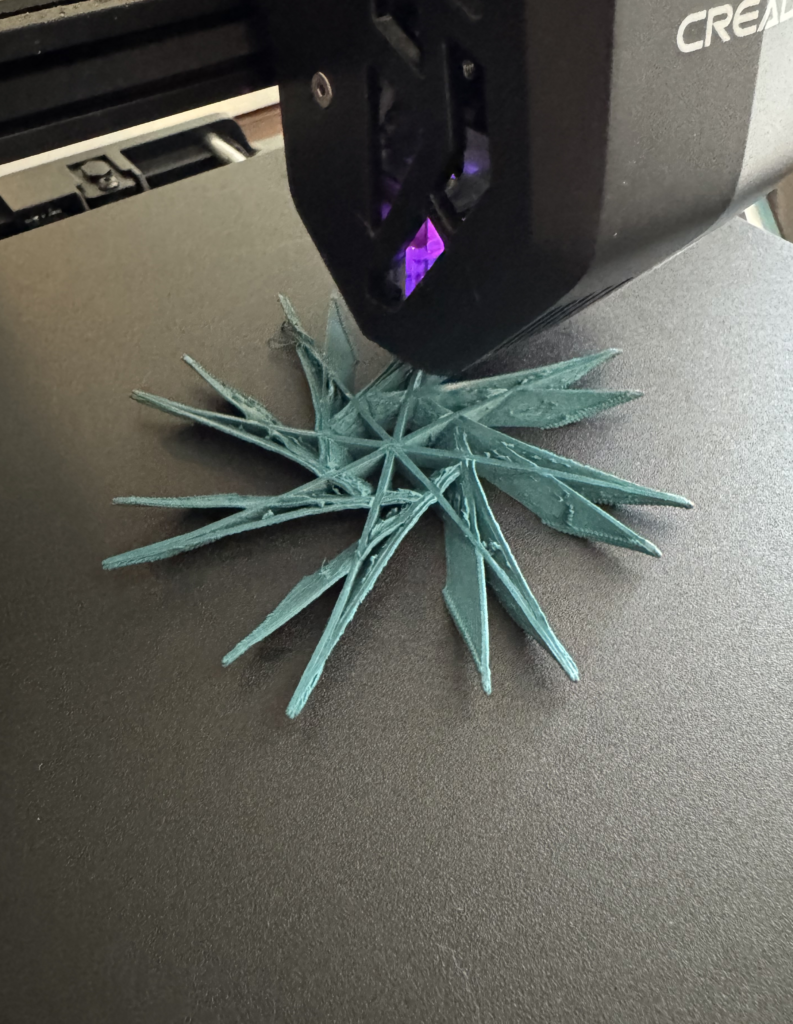

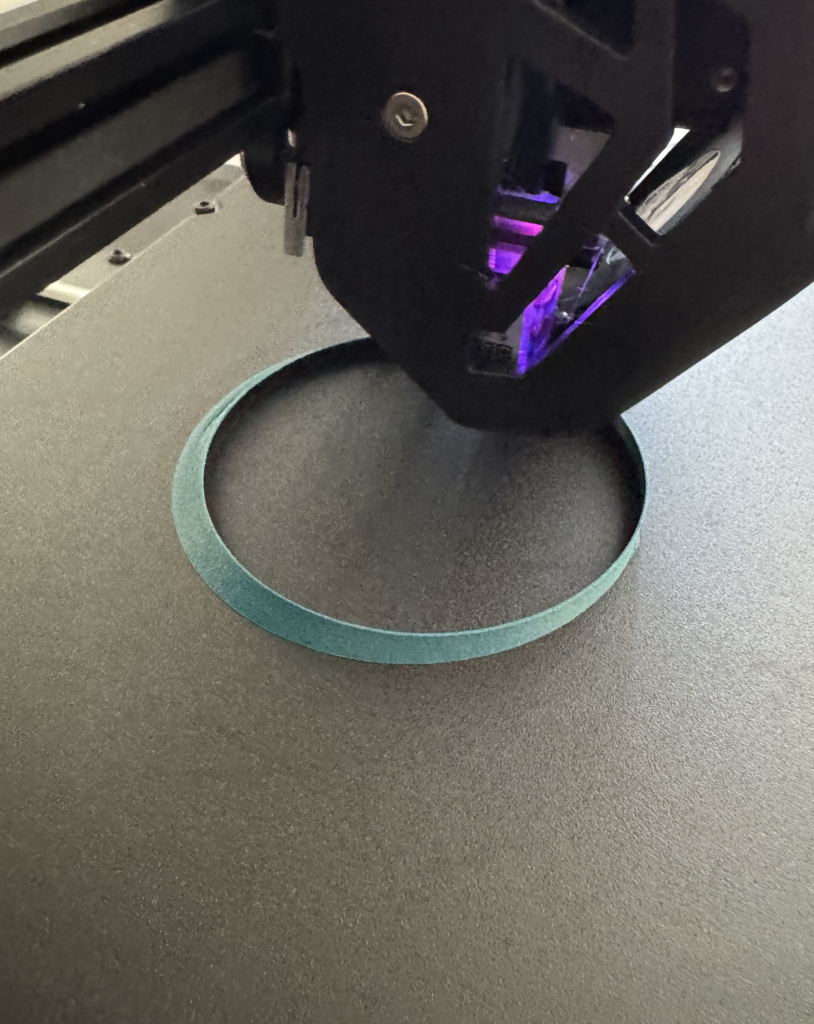

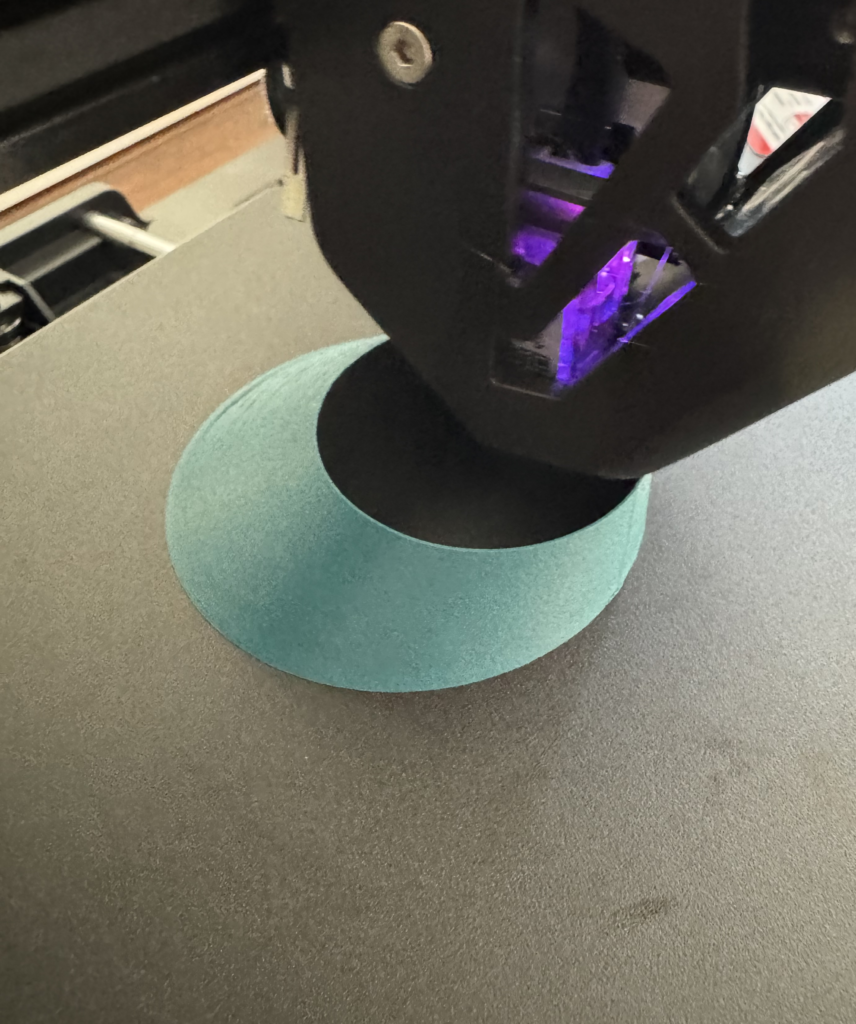

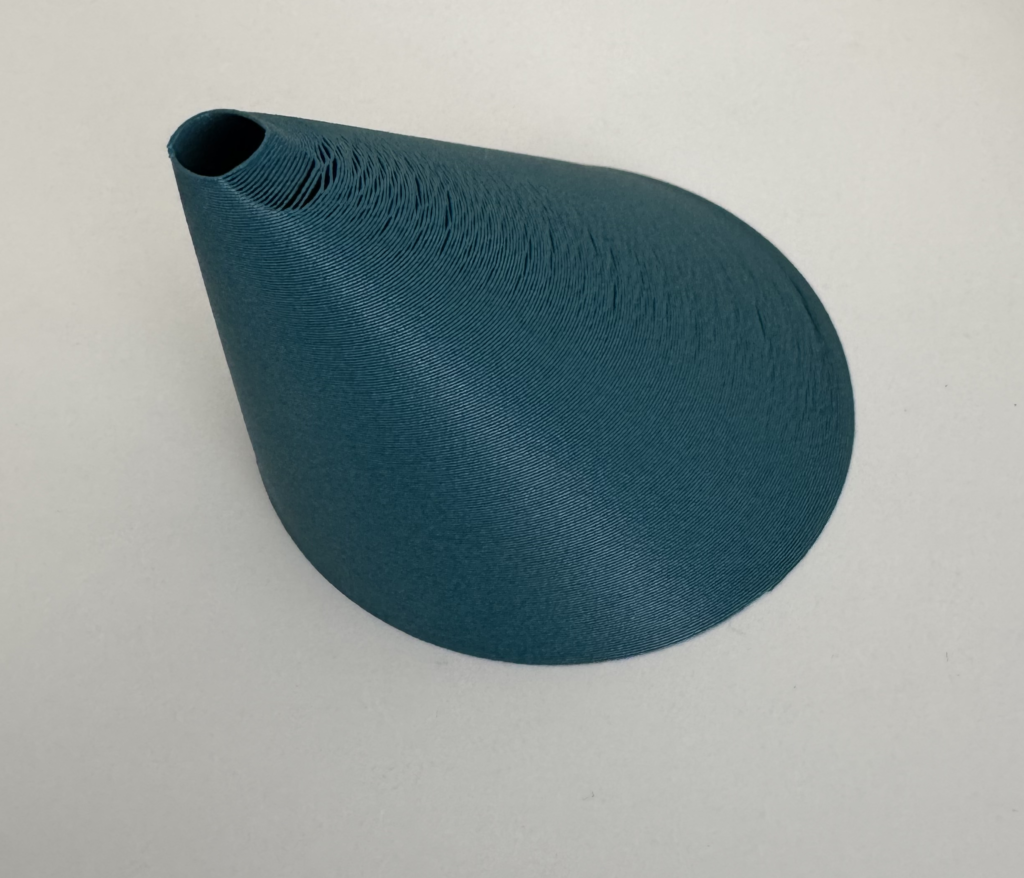

In my process of generating the three shapes, I utilized Python scripts and the Extruder Turtle Library to generate my G-Code files. I created the first object by using sine wave-modulated arms to create a star-like shape. It uses a recursive sine wave pattern to draw spikes that modulate in size and form across layers, combined with small bumps at the tips of each spike. The code loops through layers, gradually increasing the size of the spikes and the star itself. For the second object, I generated a vase-like structure by gradually decreasing the radius from the base to the top in each layer, forming a smooth, tapered shape. The third object combines a solid cylindrical base with freestanding webs of filament drawn inside the structure, forming a visually distinct pattern of crisscrossing lines within the otherwise circular form.

A traditional slicer cannot generate these shapes due to their non-standard geometry and layering methods. Traditional slicers rely on uniform layer-by-layer material deposition in a consistent pattern, typically with infill and standard outer walls. In contrast, the first object’s star shape involves complex sine wave modulation and bump creation, which cannot be interpreted by a slicer that expects uniform extrusion paths. The second object uses gradual radial shrinking, but it is the third object where traditional slicers’ limitations are clearest. The freestanding webs of filament within the cylinder represent unsupported lines that slicers would normally interpret as requiring support structures. However, in my code, these freestanding elements are integrated into the structure without additional supports, creating unique geometric features that a traditional slicer cannot handle.

Experiments & Issues

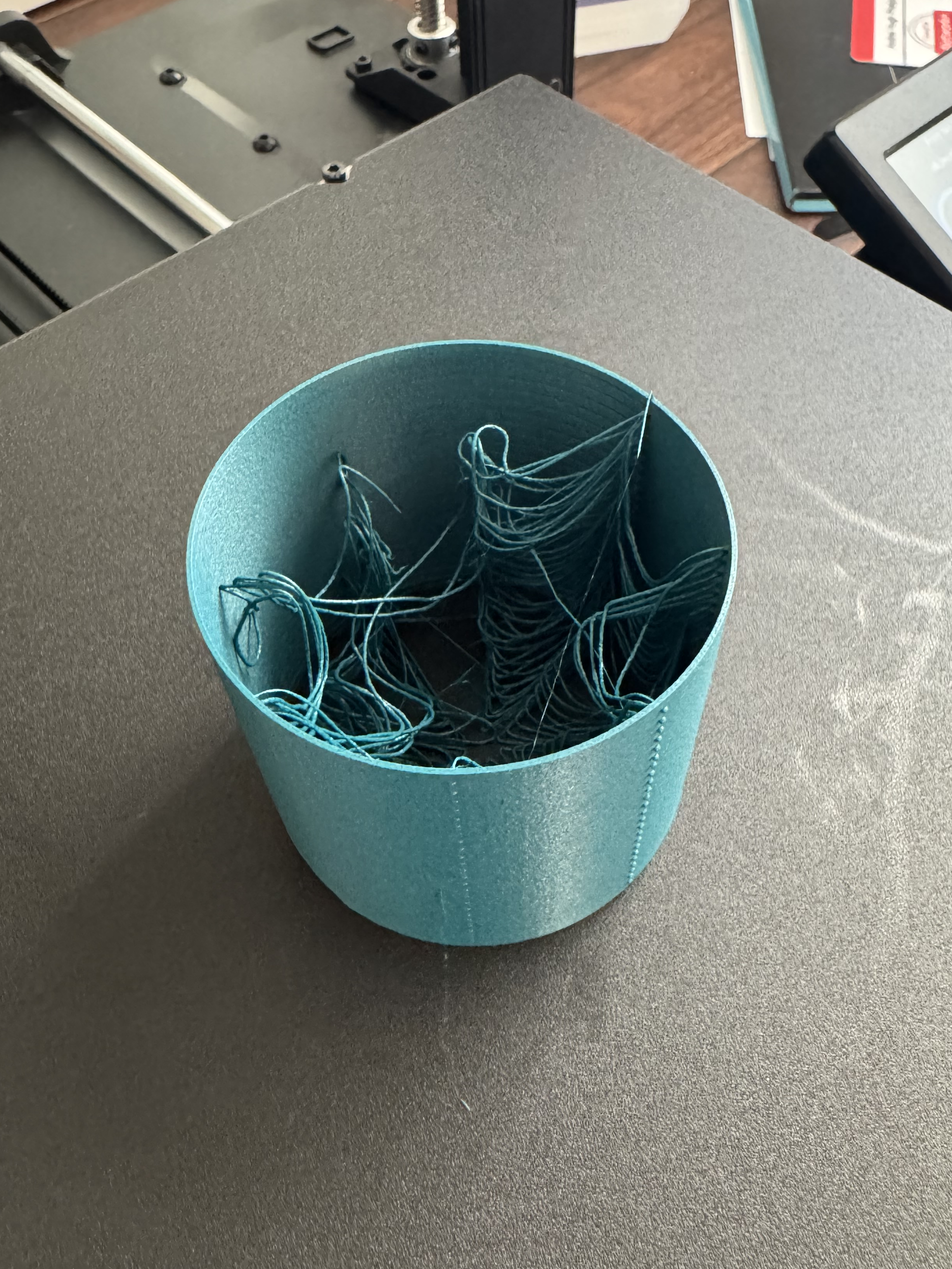

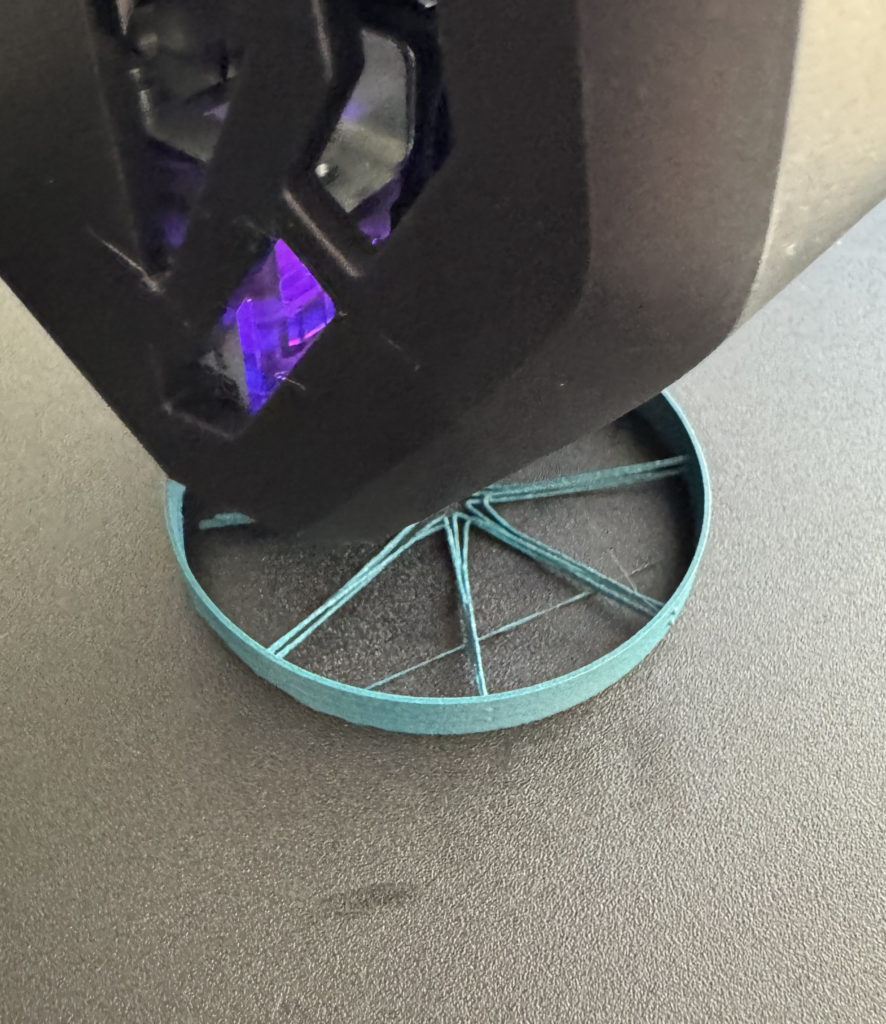

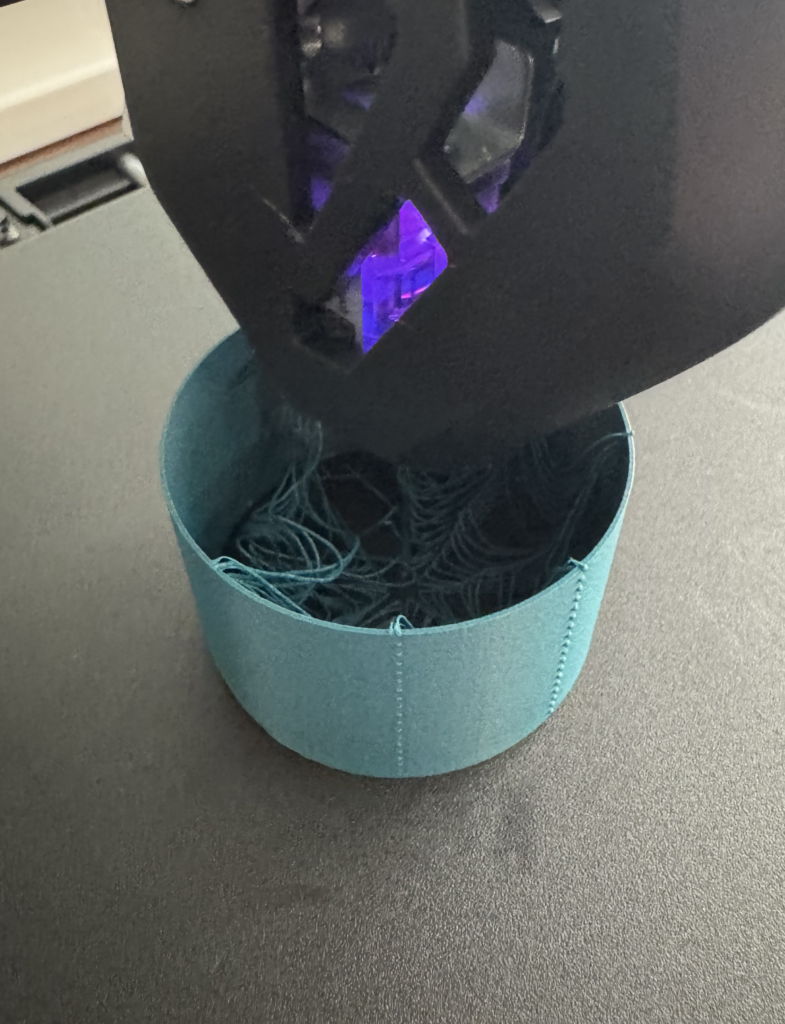

The printing of my first object presented issues like stringing between the thin points and uneven details at the tips, likely due to insufficient cooling or retraction settings. The object’s sharp edges also experienced adhesion problems, causing minor warping during printing. Object 2 was printed with excellent layer consistency and minimal issues early on, but challenges with structural stability near the top became apparent toward the end. In the final print, the last few layers exhibit a sunken effect, which I believe was due to a lack of infill. For Object 3, the freestanding web-like filament inside the cylindrical structure caused noticeable sagging, as the unsupported filament lines drooped during extrusion, resulting in loose webs. Based on the previews in Cura, it seemed this might have worked with a slower print speed. However, regardless of adjustments to print speed, nozzle temperature, or fan speed, there was still noticeable sagging in the freestanding filament.

Final Prints

Overall, I found this assignment more challenging than the others due to the high level of detail required in both the design and printing processes. It was frustrating at times because the previews in both Rhino and Cura were often misleading. Small changes in print settings had a significant impact on quality, and even with careful adjustments, some issues persisted. I wasn’t satisfied with my final prints, as they didn’t quite meet the standard I had envisioned. With more time, I believe I could have refined my designs further and achieved much better results. This experience, more than anything, taught me the importance of iteration and testing, especially when relying solely on generating G-Code to produce complex designs.

Hey Andrei! I think your shapes turned out really well, even though it looks like the printer had a little trouble with them. The first shape is one of the most unique things I’ve ever seen printed in this class. I’ll definitely have to take a look at the code when I get the chance to see exactly how you made it. I had a lot of issues with the printing process as well. Changing the speed of the printer and the heat of the extruder nozzle seemed to give me the best results. Great work overall!

Thanks for the comment!

If I had more time I would have experimented more with different printer settings. In retrospect, I could have gotten my third design to come out much cleaner and more uniform regarding the freestanding filament. I might try again one of these days to see if it’s possible!

I enjoyed your post as well! Your slinky idea was very unique. It reminded me of the butterfly-like print that was presented in class today.

Hi Andrei, I shared your frustrations with this assignment, but I think your forms turned out quite interesting. Was there something specific you hoped to test further in your iterations that you didn’t have time for? I found that working in Gcode was very powerful and like you mentioned, required much more precision for complex shapes.

Hey Sachi!

I wish I could have spent more time experimenting with different print speeds, extruder temperatures, and fan speeds. I think this would have helped a lot, especially with my third print. I had fun with this assignment, even if it was frustrating at times. I like how your “Shell” and “Anemone” designs came out. The final prints are awesome. I look forward to seeing your final project!

Hi Andrei,

I thought your first print was really cool, the sharp corners but rounded whole shape make for a really interesting design. Although the cylinder didn’t end the way you wanted, I liked the web design on the inside.