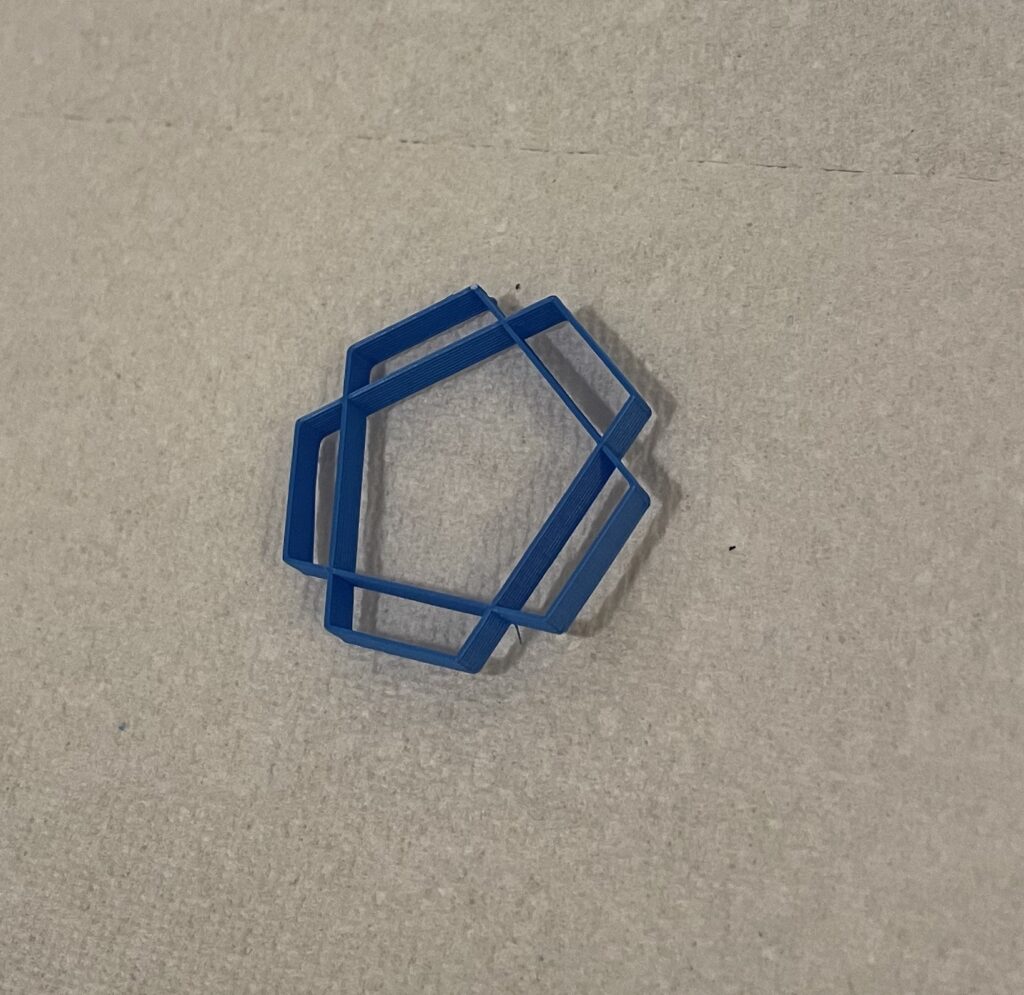

Form 1

For this project, I really leaned into just messing with the code and creating any random sort of shape- I had no preliminary ideas or examples My first shape is a sort of pentagonal intersecting shape. Here I was just seeing what the turn angles and layer height looked like printed out. This cannot be generated by a slicer due to the interweaving paths of the filament. I had to print this shape twice, but code was fine, I just messed it up removing it from the print bed. This was a good understanding of what the layer height looked like, and honestly I was really surprised my code worked on the first try so I was feeling good.

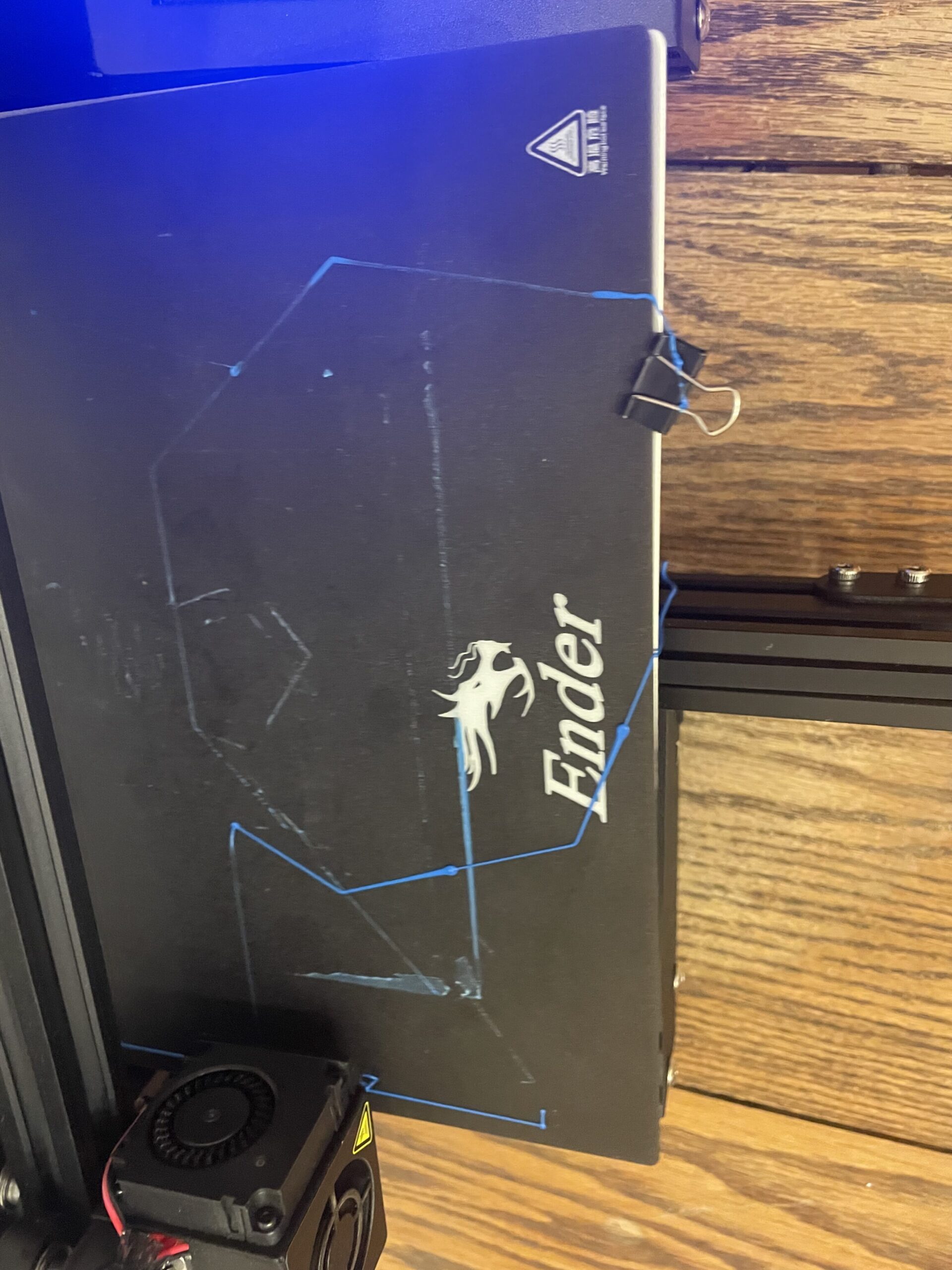

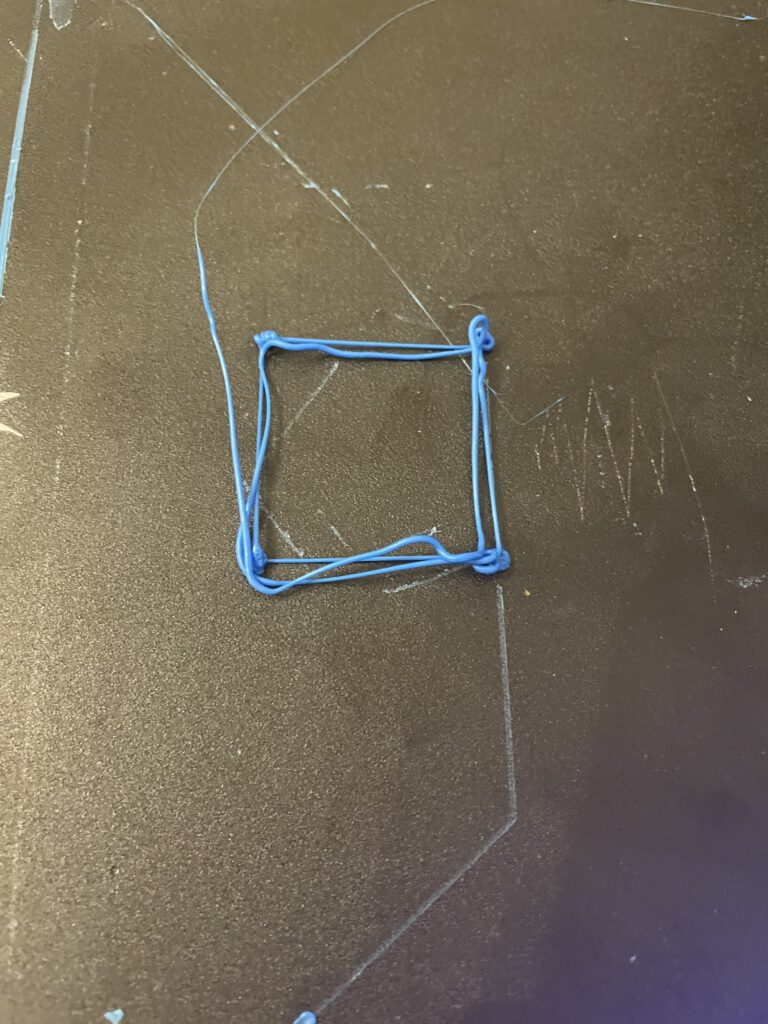

Form 2

This second form took a little more trial and error. I had a lot of issues with working around the filament extrude nodes that were produced. My first try accidentally was too large for the portion of the printer bed it was printing on, I forgot that Cura automatically centers all the prints. My second try got stuck on the lumps at the end after about 5/10 layers and so I aborted that. I had another couple tries before something started to work, and I ended up with a shape that reminds me of a boxing ring. This cannot be produced via a slicer due to the extruded extra bits of filament as well as the freestanding lines. At each corner there is 15mm of filament extruded and each layer has a gap of 1.5mm.

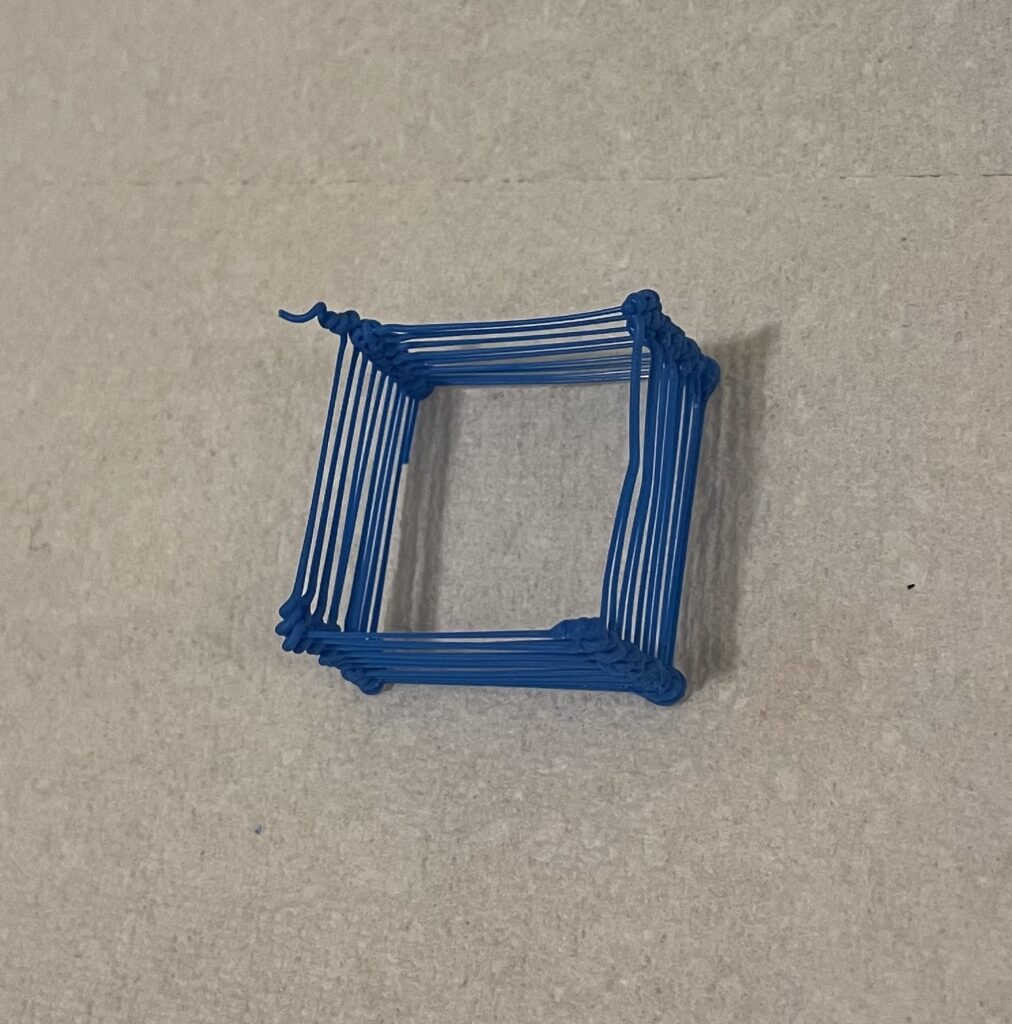

Form 3

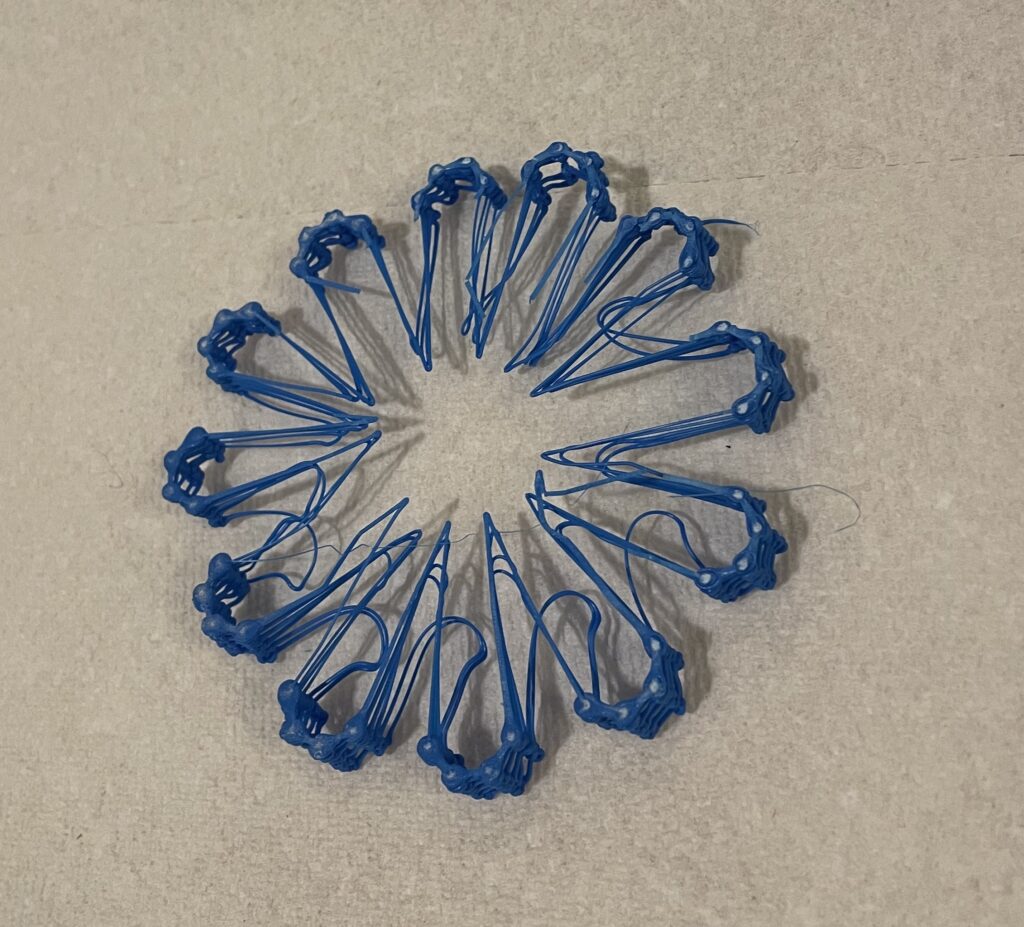

My final form I decided to start with a desired shape and then add on extra elements from there. I wanted to create a flower shape with some elements of the petal raised higher than others. This form look a lot of trial and error (I think about 6 different gcode files) before I got something I was aesthetically happy with. Some of my failed prints had weird intersecting lines that I couldn’t trace the source of, and others just did not print the way I expected. My end result (in code) was a file that would hopefully have taller ends and then go downwards in the middle. At the end of each corner of the iterated petal, 15mm of filament are extruded at the turn, but in the inner turn, no filament is deposited to create the desired elevation change. The printed result does give off that look, but it started to get wonky and ugly around the 7th layer so I aborted the print. The inner corners started to float too much and so they were warping. If I were to try this again, I would have a little bit of filament (maybe 5mm) deposited on the inside corner so they don’t float as much.

Hi Astrid,

Cool Prints! The second print definitely looks like a boxing ring. How were you able to get the lines elevated? Was it just the end points holding the center up? Having taller ends and having it go downward in the middle is interesting. I had a similar idea in my print but didn’t mess with the extrude rate. By having the print head rise as it goes outwards alters how the filament is laid. I found height too can be an issue during this process since the mass cause things to collapse. Definitely interesting and challenging prints!

Thank you Ricardo 🙂 I had a slider that was layer height, so I just messed around with that. For reference, my first print was .5mm and the boxing ring was 1.5mm, but it also had 15mm of extrusion at each corner, which probably added some height.

Hi Astrid,

Your prints turned out beautifully! How did you generate the endpoints of the boxing ring? Did you increase the extrusion rate there, or stop the print head perhaps? I really like how you approached your flower, I would never have thought of building it the way you did. Very cool project!

Thank you Liz! The ends of the boxing ring has 15mm of extra extrusion. I didn’t forcefully code a stop, but the extrusion stopped it for a second or two on its own.

Hi Astrid,

The concept of stopping in place and printing filament to create structures was totally new to me and I really like how you used it in your models. The boxing ring like object is really self explanatory, I love it. Your flower like shape concept is really nice. During my trials I experienced similar problems with warping, I think the difference in thickness may have something to do with that. I think your Idea of extruding extra material at the thinner part of the petals would help the model keep its shape more consistently.