Design Process

First of all, I’m really grateful to the Accessibility Recourse Center and Dr. Buechley helping me with an extension during this assignment as I was dealing with extreme health issues these past few weeks. I had never really had to utilize these recourses UNM has to offer, due to my good health before this but I am so grateful that UNM has this program set up to help students struggling with health issues, and I also have a newfound respect for anyone out there struggling with health issues as I now know how difficult it is.

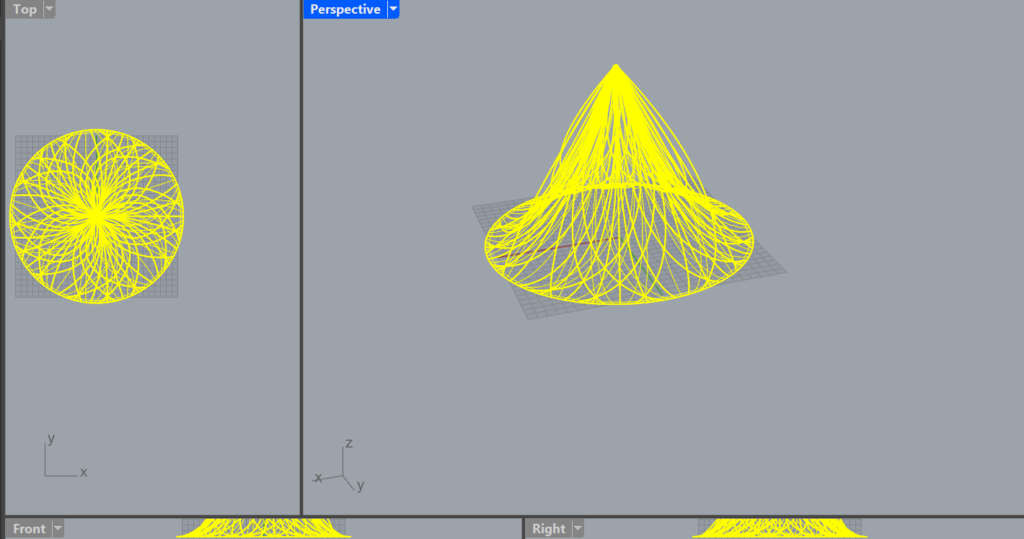

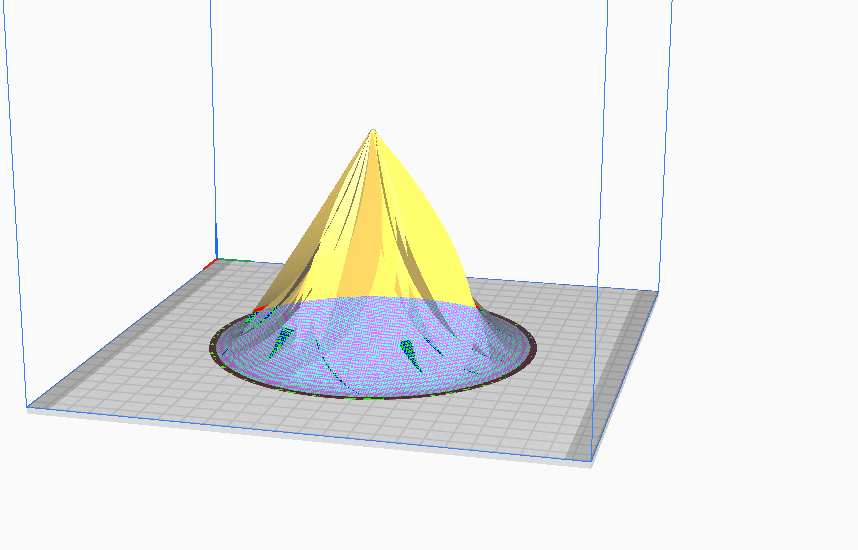

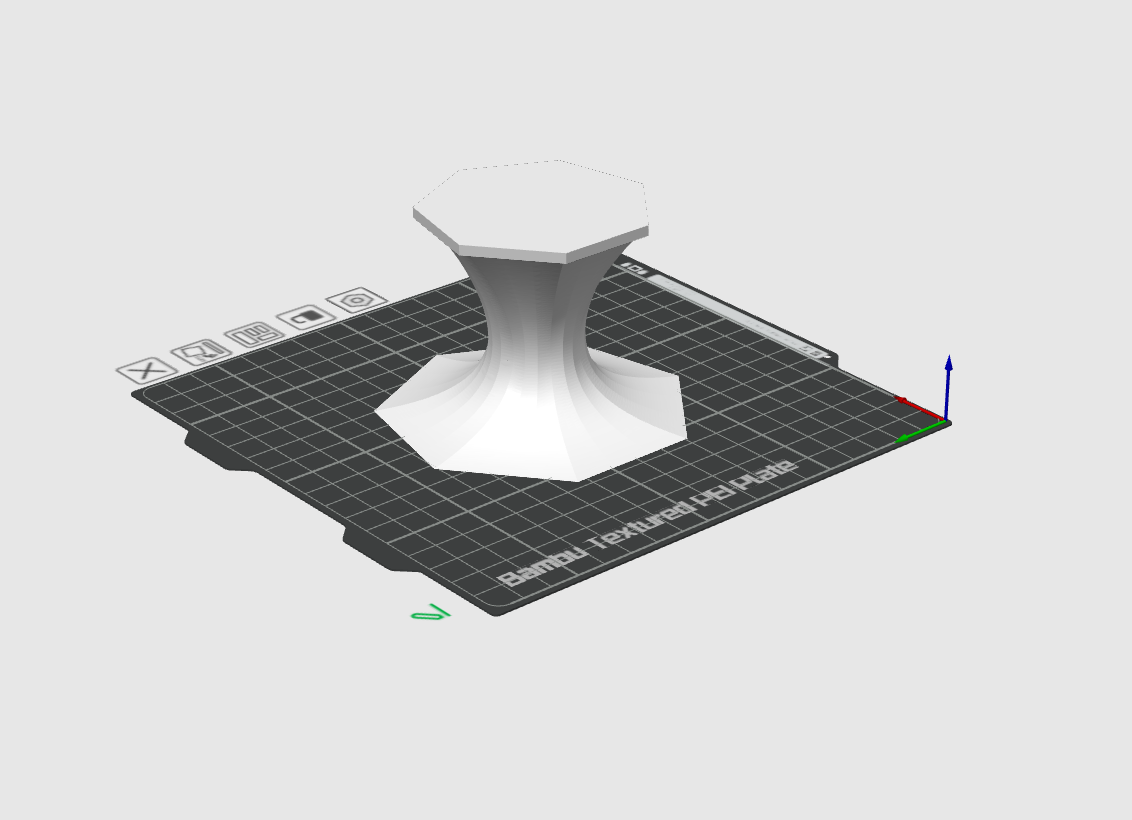

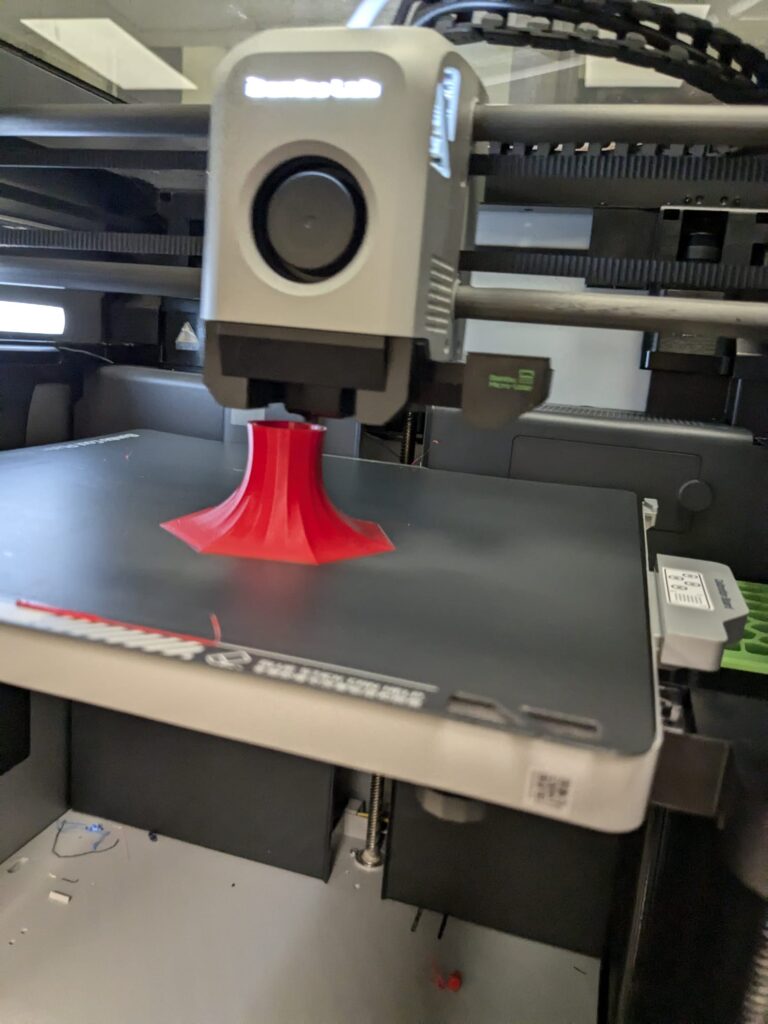

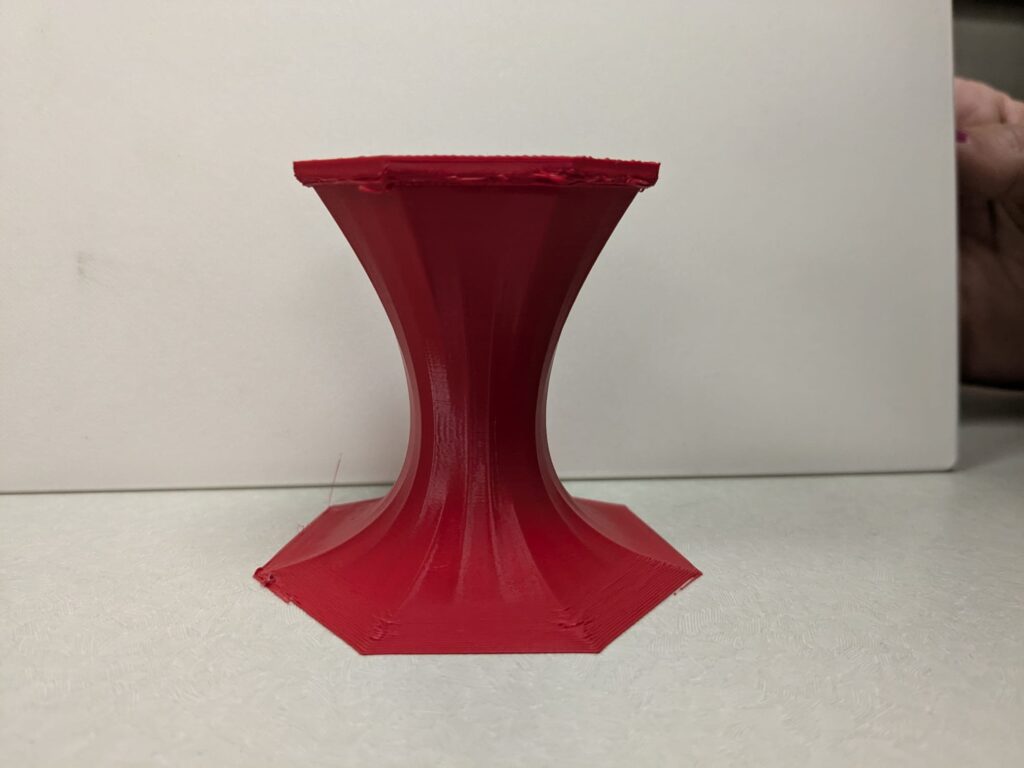

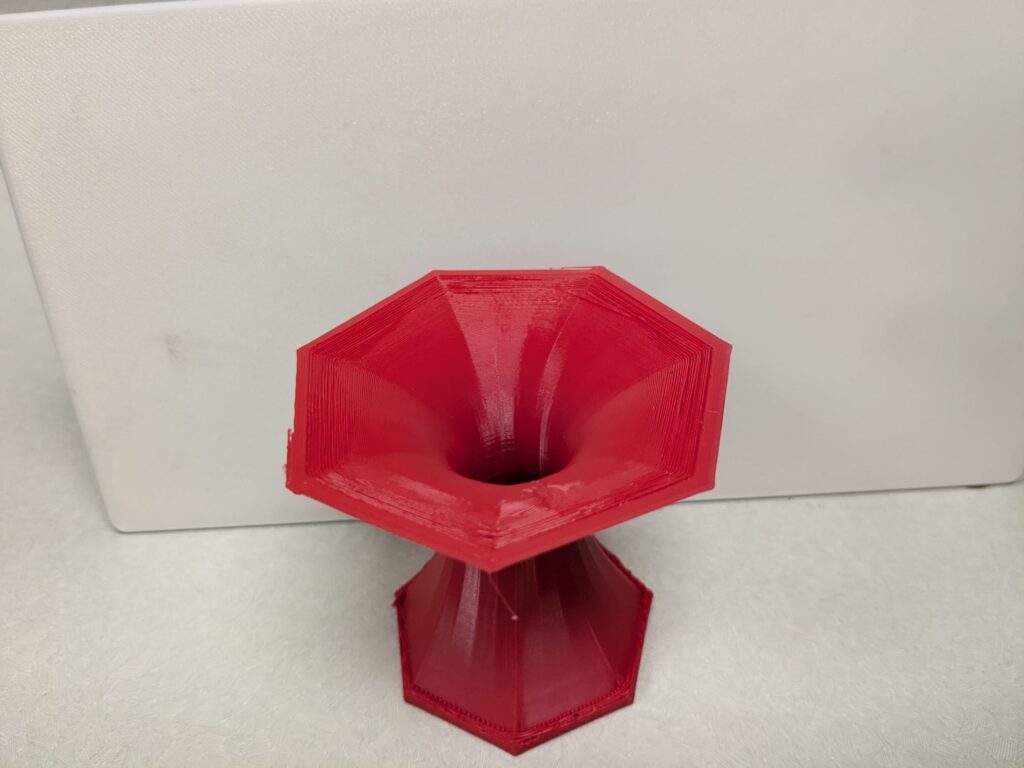

Anyway, back to my design process. For my design process I decided to stay on the safer and slightly less experimental side due to a lot of issues that my printer at home was having with more complex designs, so for my 3 prints, I decided to ensure that the in class python code implementation was up and running, and then I began to modify and add the additional slider parameters to modify the cylindrical shape I created in various ways. For my first print, I wanted an organic yet visibly well planned and modern object, so I decided to adjust the input data from the sliders first contort the object into a cone like figure. I then adjusted the other sliders to add organic looking textures and grooves to the sides in order to make it more organic looking like a small mountain you might see in nature.

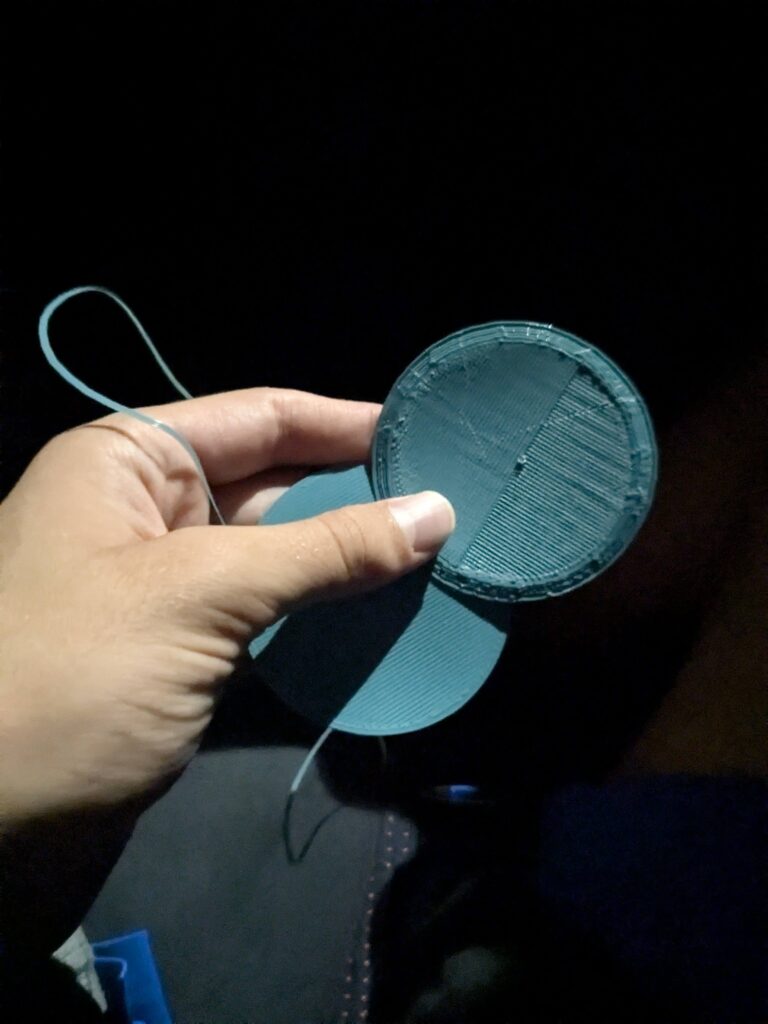

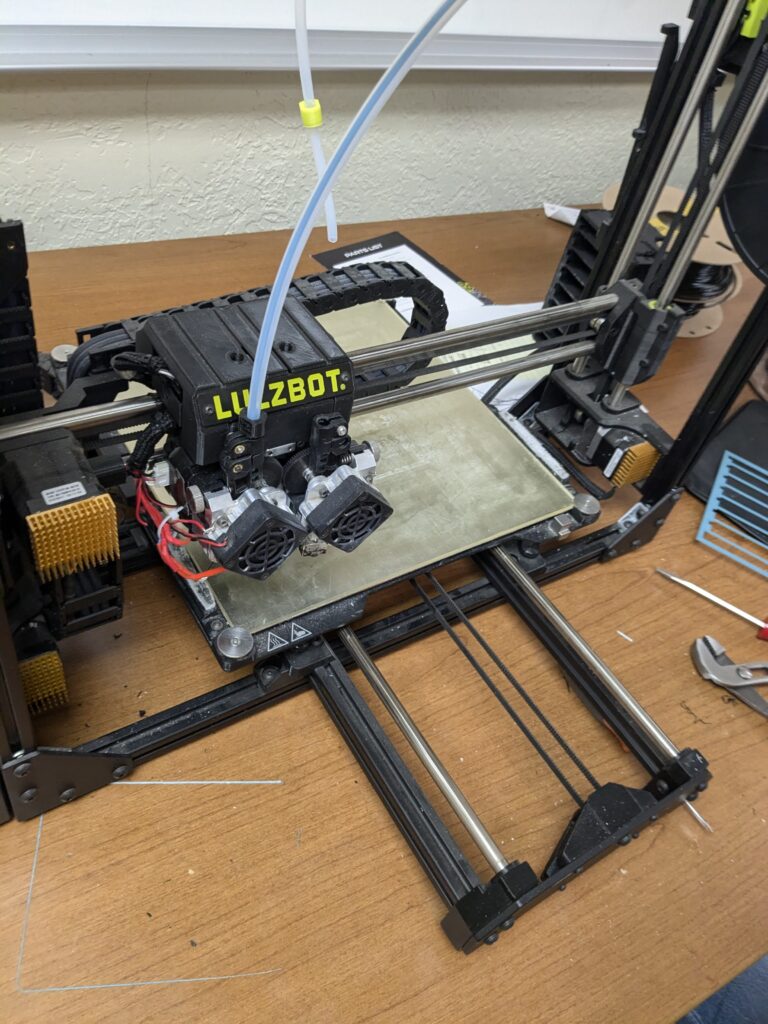

To be honest, my printing process on this was extremely difficult due to the amount of roadblocks I had both with my printer at home and then the printers I was attempting to utilize at the Mechanical Engineering building . I ended up discovering several small bugs in my python implementation which was quite time consuming to figure out where these glitches were coming from , the hardware I was using, computer, printer issues, or my implementation in rhino / grasshopper, but after a long process of trial and error and troubleshooting, I was successfully able to create a clean and successful printing routine.

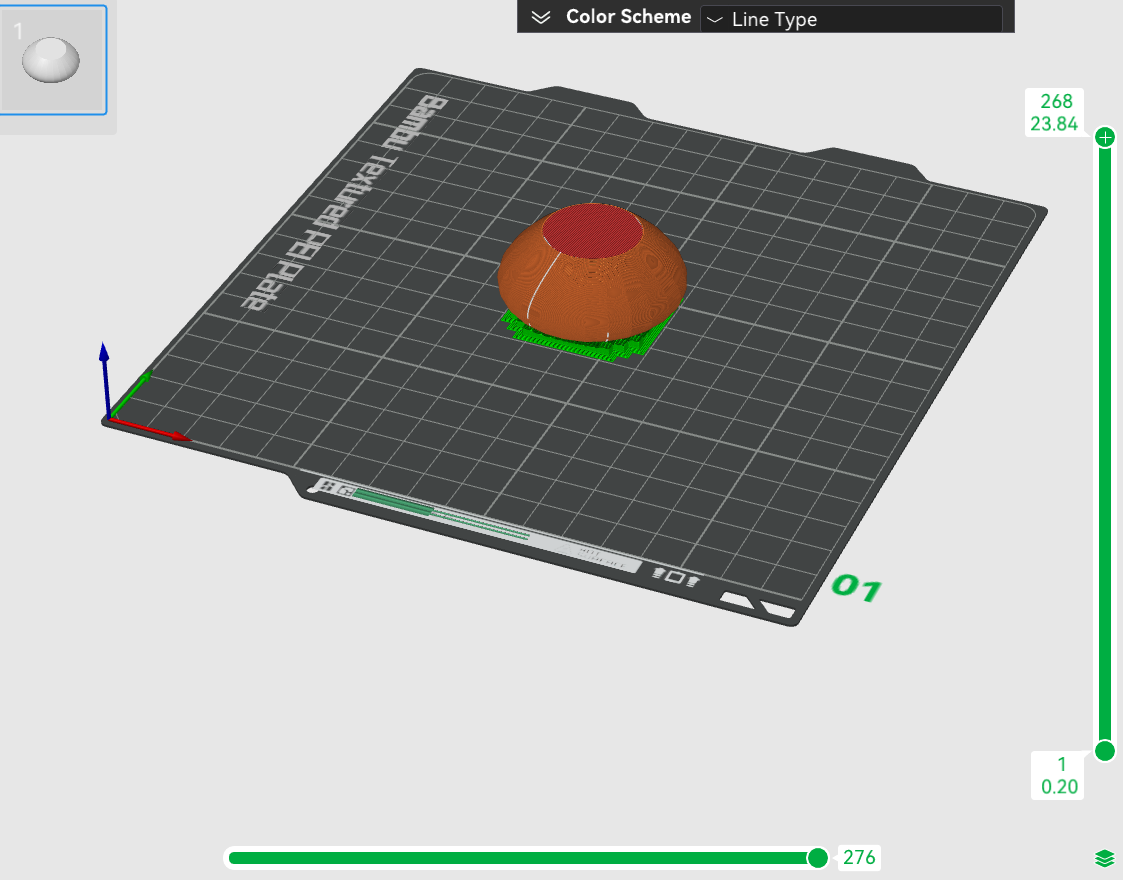

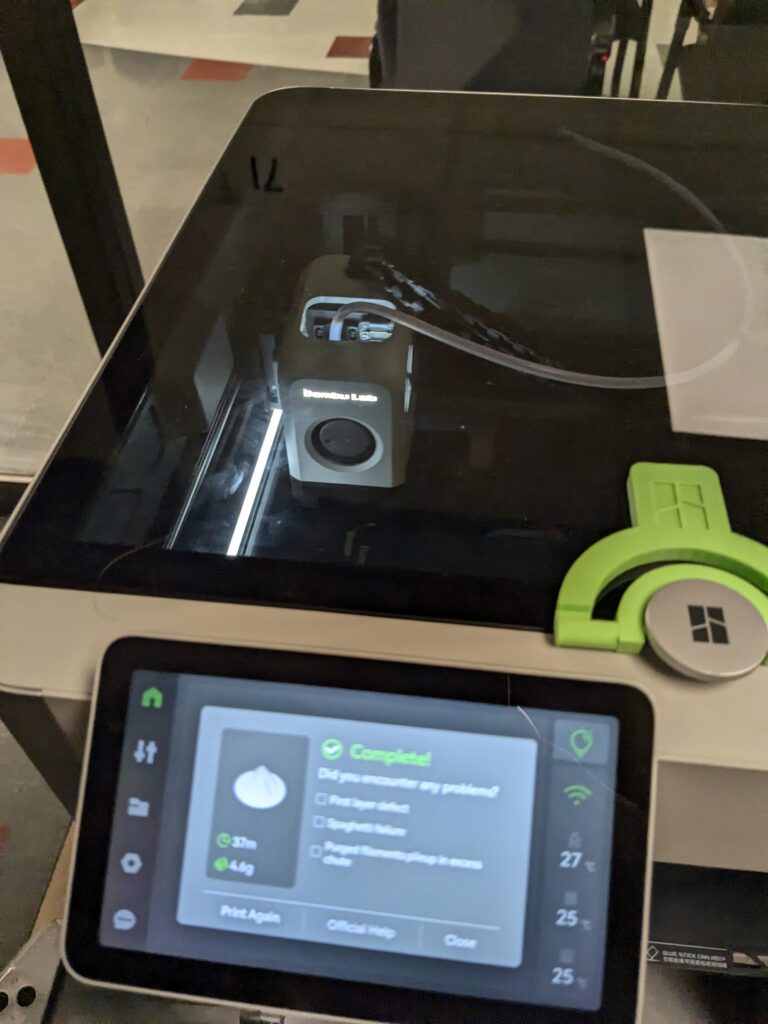

After failing on both my home printer and losing access to this lulzbot printer , I decided to bring my efforts to the mechanical engineering lab printers and here thankfully I was able to make a lot better progress and flattened out the bugs in my grasshopper python implementation as well. The printers in this lab actually did not use cura but instead used a similar program called Bambu studio, but everything on this software was thankfully relatively easy to learn and similar to cura.

Reflection on the Parametric Design Process

Although on this project, I had many roadblocks and frustrating printer issues (including annoying filament jamming issues on my ender 3 at home, I thought that the process of parametric design is so extremely cool and exactly what I feel passionate about creatively when it comes to computer science in comparison to other engineering fields (in my opinion). I think it is so awesome how utilizing math, programming , and creativity that these truly unique structures can be fabricated. It was really cool to see how these math equations and functions can be used in a real life hands on scenario and fused with my own artistic creativity. I really think that this combination of creativity and technical expertise is so extremely cool. I find it interesting how this type of design differs from typical arts design in a sense where everything is significantly more precise since it is made from a computer / machine as oppose to a human use handheld or perhaps tool based skills. As I’ve learned from my efforts in this project, I think that parametric design enables us to come up with vessels and structures that are just not possible (especially in the sense of precision / weight balancing etc ) from using other human based artistic / fabricating tools.

Creative Agency and Intent

While making these objects one thing I definitely had in mind is the fusion of organic, industrial, and technological features in the compositions of my art pieces. I especially feel proud of my triangular organic looking mountain shape which I personally think looks like a interesting blend of an organic object you might see in nature with a more linear / symmetrical / industrial fabricated look. I feel especially inspired by the cyberpunk aesthetic portrayed in a lot of movies / games , two of my favorites being the watch dogs series games and cyberpunk 2077, throughout this course , I hope to be able to continue this aesthetic of blending organic and technological looks.

Finished Prints

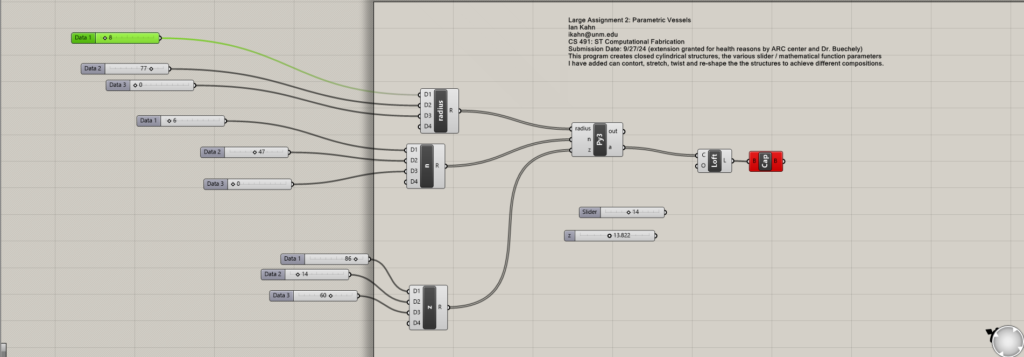

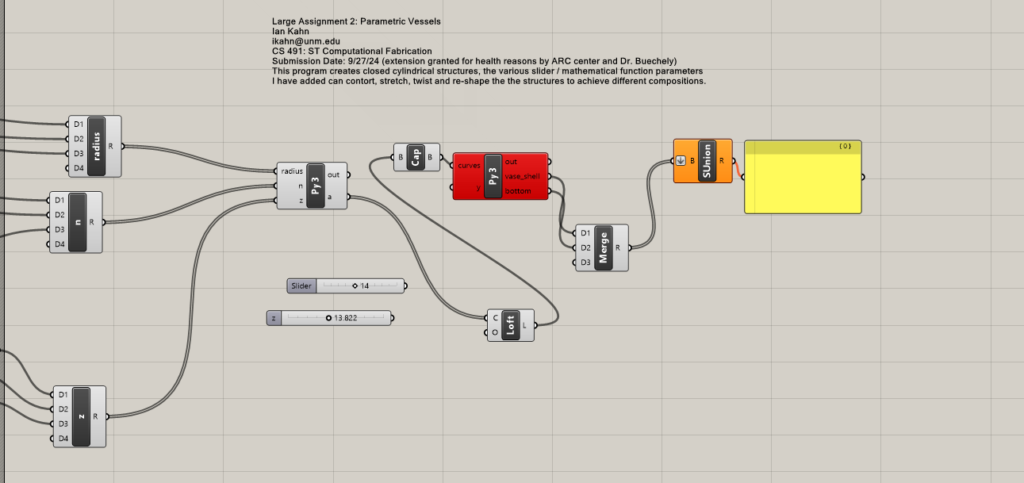

Above is my grasshopper code I used, it is essentially a slightly modified version to include slight mathematical / functional differences of the one we replicated in class lecture.

Hi Ian,

I like your design, especially the top view of the first one and the creation of a tent-like model. Im glad there are resources at UNM to use and help debug issues in 3D pointing. How does one go about to use them? is it a first come first serve machine? I thinking taking inspiration of movies and games can help design yours models and take a sense of pride in them. Great post.

Hey thanks so much Alan! I really appreciate it. Yeah so you just have to go to the mechanical engineering office and apply for access. Thanks again man.

Hey Ian! I really liked reading your post. I think you did a good job of highlighting the difficulties that we face when making 3D prints, especially with deadlines. It can be a long process to get through all the issues that can arise when we actually let our printers start the printing process. I think the dedication to see the project through to completion is very inspiring and I am glad you got things to work out. I really enjoyed this project of yours and I am excited to see what you will make in the future!

Hey Wayne, thanks so much for the comment! Yeah it was a pretty time demanding project, but I’m grateful for everything I learned throughout this process and I am confident I can now be more successful with my skills now with these in the future. Thanks again for the comment, and your projects are looking great as well!