I have been able to complete all of my deliverables to date, except for casting the generative ring designs.

- Structure manufacturing limitations: My Grasshopper file includes models for both the casting flask and build volume of the 3d printer. If there are collisions between the sprue, flask, and build volume, the file will throw an error.

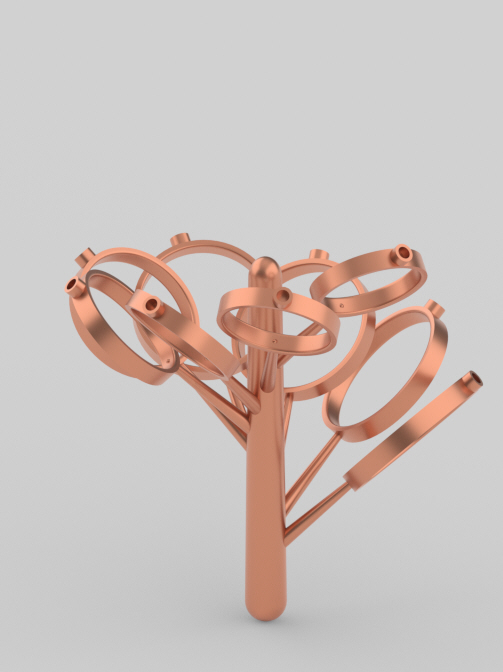

- Model sprue base, basic ring shapes: The sprue base is a straightforward model and is included in the main Grasshopper file. For ring shapes, they are separated out into a different Grasshopper file and connected to the main one through Hops, as the rendering can be intensive depending on the choice.

- Place models around sprue base, generate connecting sprues: Completed, but there is an opportunity to compress the sprue further to allow for more models on the sprue base.

- Add settings and bezels to ring shapes: Completed. Like the ring base, this is separated out into a separate Grasshopper file to keep things neater in the main file.

- Voronoi-based generative designs for ring bands: Completed, though there are some manufacturing concerns.

- Print and cast: I have printed and cast a base ring with a 2.5mm cubic zirconia cast in place and printed my other models (though there is some concerns).

Bumps in the Road

- 3D printer model limitations: Some of the standard jewelry sizes (bezel wire, for example) are very thin–32 gauge bezel wire is 0.203mm. The minimum recommended resolution for the FormLabs 3 that I am using is 0.3mm. The generative design and bezel settings that I printed are extremely fragile, and many of them tore apart when I was removing the supports. I could repair them with wax, but it’s a question of using my time efficiently–I could also make adjustments to my code and reprint them.

- Timing: The equipment and tools that I am using are moving the second week of December. I have to have everything ready to cast before they move, and I have been coordinating with a casting partner to maximize materials and gas usage for the J2-R casting machine.

Photos

Hi Liz, this is so very neat! Those bronze rings look amazing. I bet it will be even that much better once they’re polished! What a very neat progress. Good luck with finalizing everything.

Yeah, it really comes out when it’s all polished, and it feels really good when it gets past the ugly stage! 😀 It’s really fascinating to see just how much detail the investment plaster picks up the details of the print–you can subtly see the print line layers on the cast metal.

Hi Liz!

What an awesome implementation of your project proposal thus far. Something just tickles my brain with how your sprue generation has turned out. I also really enjoy the generative design on the bands, though they are fragile as you’ve said. It looks like a really exotic candy to me for some reason haha (printing with molten candy sometime perhaps?).

I really like how elegant my initial sprue packing looked–alas, it is a costly use of materials, so I had to compact it a lot further. Something something function over form.