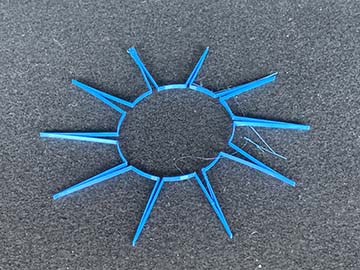

I started off printing the GCode generated by the Rhino/Grasshopper programs which gave me a general shape and also helped with the printing size. Creating a code that allowed me to change the shape of my object by amplitude, oscillation and size. Depending on the parameters set into the Grasshopper program you could come out with beautiful forms and shapes or very jagged and rough shapes.

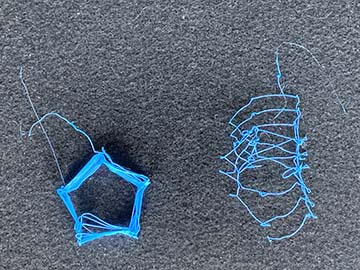

Shape 1: This was more of my trial and error piece as I was trying to hone in the printing parameters and playing with only the code that I created in Grasshopper. This allowed me the chance to get the machine and my mind to work more in sync. A few simple shapes were formed after a little trial and error.

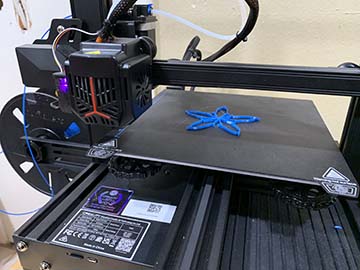

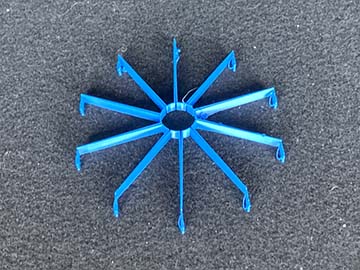

Shape2: With this shape I was trying to manipulate the machine to make long drawn out spikes, literally anywhere on the shape and was not very successful. In fact, at the 50% mark of all my shapes being printed the machine would start acting up. Lifting the extruder head about 20 mm and then homing itself back to the starting origin tapping the relays on the machine. Eventually I had to stop the machine and start all over. This got me to look at the GCode itself that was generated from Grasshopper. This started my debugging mission. I found at half way through the code, it had stopped the original code, reset itself and then made some other code that was having it continuously tap the relay switches. After deleting the extra code, all was well and I was able to make a much cleaner shape.

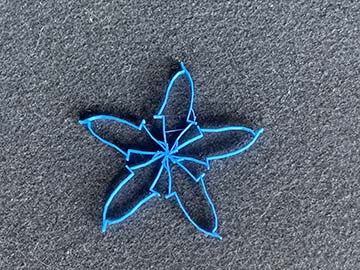

Shape3: Now that I found how to fix the actual code and manipulate it within the GCode space itself I started playing around and trying to get my filament to become long and hair like. This seemed to be quite the difficult task as I had to find the points at with to extrude longer lines of filament. After studying the code and playing with it I started seeing the patter within the GCode space and started manipulating by adding lines, deleting lines and playing with the Extruder rates along with speeds. In the end I wasn’t quite able to complete what I set out to do but I’m happy with that I learned. I’m completely able to figure this out but it will take me some time as I’m not a coder by trade.

A traditional slicer has rules and parameters that it must follow to produce normal objects your able to create in a 3D program like Rhino. But unlike Rhino, writing the Gcode ourselves we are able to manipulate what the machine is willing to do by default in essence letting us extrude filament at different rates with different movements not allowed by the usual slicing program. With this type of creativity we are essentially mixing our minds with the depths of a computer, a program and a machine that listens to all the code begin produced.

I went into this project extremely intimidated due to my lack of coding skills. In the beginning this was quite the mess and I was unable to implement even a percent of what I wanted to actually do. By the end I could start reading and understanding the Gcode as if I learned a new language. My writing skills in this new language are questionable but I’m starting to be able to read and understand code so much more even between different machines and programs. So in all this was definitely the most challenging assignment but I’m ecstatic that I’m learning so much about the world of coding and it’s creative side.

Hey Christopher!

I really like the shape of your prints, they turned out really cool. I’m not too sure why the gcode would break for you like it did, but you handled it and your prints turned out really cool because of it!