One of the things that I discovered in my small metals classes was how much I liked making rings. Finding rings that were comfortable to wear and fit me, not to mention aesthetically pleasing, was a hard task, and learning how to make my own rings was a revelation.

However, in a production environment, making rings one at a time to serve a wide variety of finger sizes is…tedious at best. For more unique setting designs and styles, the labor involved to make enough inventory is prohibitive. The more complex a design is, the more difficult it is to make them in quantity.

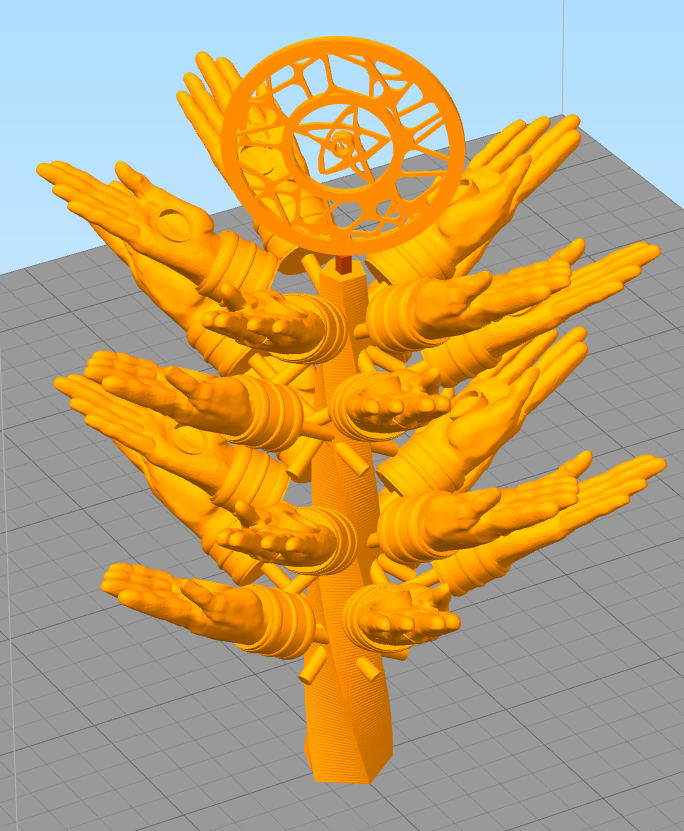

With this project, I want to take advantage of my sculpting and modeling skills and apply parametric design principles to generate a casting sprue that I can 3D print in castable wax resin. Of importance is to be able to distribute the models along the main sprue to make the most of the materials, casting process, and time investment.

Project Considerations

- Model ring sizes (US, UK, mm): There is no consistent, universal standard of sizes, so I will need to generate sizes based on a changeable input list. There are two types of band styles; standard, which is flat on the inside edge, or comfort, which is more rounded. I want to minimize the cleanup portion of the production process as much as possible, so I will focus on the comfort band style.

- Stone settings: Scaling up and down a model is not the best method when involving settings. Stones usually come in a specific size, and sorting stones based on minute variations is, again, tedious. Being able to change the ring’s circumference while not changing the setting size is a point of consideration.

- Account for material density and manufacturing limitations: Different metals have specific gravities used in casting calculations, and depending on the casting method, there are weight limits of the crucible. There are also limitations on how much space a sprue can take up in a casting flask, and casting flask sizes vary. For the purposes of this project, I will be structuring my designs to work with the Neutec J-2R Casting Machine.

Generative Design for Ring Surface

My main computational point for this project is going to be based on Voronoi diagrams. A Voronoi diagram involves a set of random points and creating a boundary based on the nearest other points. Once these points and boundaries are generated, there are several different approaches to what I can do with that data.

- Assign a “weight” to each point and extrude the boundaries to that point.

- Create a border from the boundaries and remove the interiors if the area is below a certain size

- Remap Z-axis of points based on proximity to the “top” of the ring

- Add stone setting site based on the size of the Voronoi cell

- Add array of primitive shapes along Voronoi boundaries that decrease in size the further they are from the “top” of the ring

Deliverables

- Structure manufacturing limitations

- Model sprue base, basic ring shapes

- Place models around sprue base, generate connecting sprues

- Add settings and bezels to ring shapes

- Voronoi-based generative designs for ring bands

- Print and cast: Basic shapes plus tube settings for 3 and 5mm stones; generative ring designs

Timeline

When I am able to cast is dependent upon class schedules at FUSE Makerspace and coordinating with the jewelry lab technician. My timeline might shift around accordingly. Edit: Consulted with lab technician to coordinate casting times.

- October 23rd through 27th: Build base structures in Grasshopper, including consumables calculations; model base ring shape

- October 30th through November

3rd1st: Sprue modeling and packing November 6th through 10thNovember 1st through 3rd: Setting and bezel modelingNovember 13th through 17thNovember 6th through 9th: Print and cast basic rings- November 3rd through 9th: Generative design

- November

27th through December 1st10th through 14th:Generative ring print and cast - November 15th through December 6th: Ring cleanup

- December 6th through 10th: Final Documentation, Photography

- December 11th through 16th: Final Presentation

Related Work

- Hybrid Craft: Showcase of Physical and Digital Integration of Design and Craft Skills

- Yael Friedman’s puzzle rings provide a new way of looking at jewelry and wearable objects. Fidget objects are popular, and puzzle rings (or spinner rings) feel like an evolution of that.

- Jessica Rosenkrantz: Growing Objects

- Jessica is the creative director of Nervous System, Inc. The kind of fluid, organic shapes that they are able to achieve in inorganic materials is inspiring and I like that kind of contrast in my own artwork.

This looks really fun especially being able to wear your designs. Have you done jewelry before this? I imagine you have and to be able to implement a new way of designing should be about some really interesting pieces of work.

I have! I actually have a Bench Jewelry certificate from CNM that I got as a part of my associates degree and learning how to work with metal has been great fun. Part of that though is identifying where I wanted to spend my time, and repetitive work immediately makes me want to find technological solutions. The neat thing is that approaching the designs with an eye towards unique pattern generation is that even though the designs might be in a series, they will still sand out from each other. The wax is destroyed in the manufacturing process (hence the term “lost wax”), and while I could just reprint the same model…where’s the fun in that? 😀