Inspiration

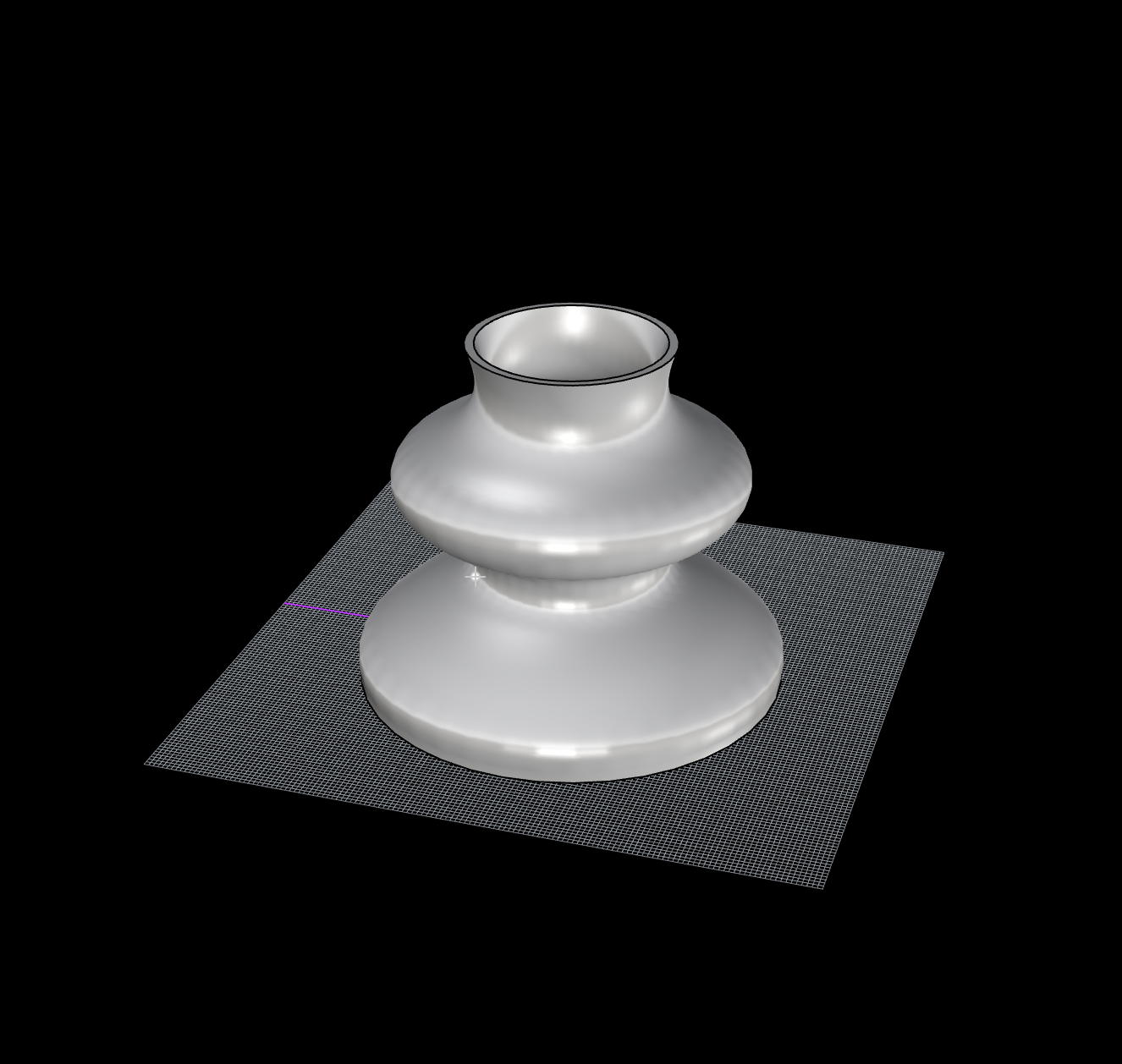

The inspiration for my parametric vessels comes from glass bubble candle holders, an example depicted to the left. I have loved the shape of these candle holders ever since I originally saw them. Their shape was also perfect for reproducing using Grasshopper so I decided to create my own version of them.

Design Process

Designing objects through programming was definitely a different experience to using something like SOLIDWORKS. For this project the format was perfect especially as you could quickly change parameters to get spectacularly new and visually intriguing results. However I am not sure I would want to attempt to use programming to design an intricate part that needed to meet specific requirements. This is due to the additional complexity of having to add additional components for any part that doesn’t follow a repeatable pattern. It is far easier playing around with parameters to get a cool result than it is to create a deliberate design. Maybe with more practice designing with intention would become easier. I do want to further play with what I learned during this project to see how complicated I can get the artifacts.

Creative Agency

For my parametric vessels I had an idea in mind that I was trying to create. An example being steadily growing bubbles that got wider towards the base. While I took inspiration from existing objects, I never copied these objects directly so I still feel like I can take authorship for the design. This despite the fact that a program was used in the design, because I was still the author of the program behind it. I directly contributed to the parameters that created the vessels shape. If the objects were created using machine learning techniques I might feel differently about the authorship as I wouldn’t be the one manipulating the final form. However, I believe that because I had a design in mind that I was actively trying to create this allowed me to feel greater possession over it.

Problems

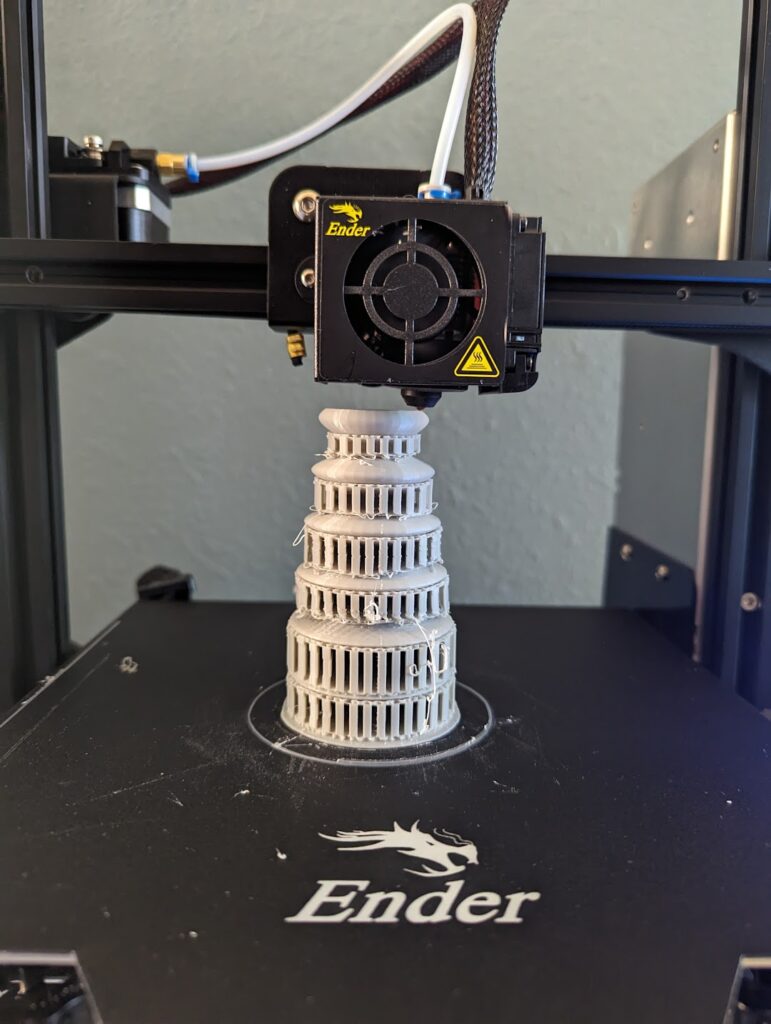

Unfortunately I ran into several problems with this project that made me less than happy with the final fabrication. However I have learned from the issues that were my own fault and I will be able to better approach future projects. The first issue I encountered was my printer jammed halfway through my first print and I had to pull apart the entire mechanism that feeds the filament to the nozzle head. After this the filament became uncoiled from the spool and jammed the print partway through again.

My original code set the size for the vessels to that of an actual candle stick holder as I was planning on being able to use the fabricated objects. I knew that it would take much longer than the 10 hours, however I way under estimated the time. Instead of editing the values in Grasshopper I just used Cura to scale down the design to a reasonable print time. I didn’t consider that scaling down the print would reduce the wall thickness as well which caused major issues removing the support structure. As removing the supports in some areas fully ripped off the walls of the vessel. I would have gone back and made the size changes in Grasshopper however I was unable to given the time constraints on the project. Instead I repaired the vessels as well as I was able.

Hello Lasair! I love the forms that you created and that you had an inspiration. I agrees that you can totally take authorship, and that it may become more of a gray area if machine learning were involved – I think it’s definitely important not to just label computer technology as taking away the creative agency of the individual, because it can be a really awesome tool 🙂 I also scaled down some of my models in Cura and didn’t even realize it affected the wall size until you had mentioned it in class – some of my walls were totally smaller than the others even though they all had the samewall parameter in grasshopper. I didn’t scale mine down that much so it didn’t make too much of a difference thankfully but I’m glad you pointed it out so I know in the future. I love your designs and the desired functionality, and the way that you can rotate the base of one of them is pretty cool even if it wasn’t planned.

Hi Lauren! I am glad I wasn’t the only one who didn’t consider that scaling everything down would also affect the wall size. When I pulled the supports off and realized there was only a single layer between that was getting ripped off as well it felt like such a huge palm to face moment.