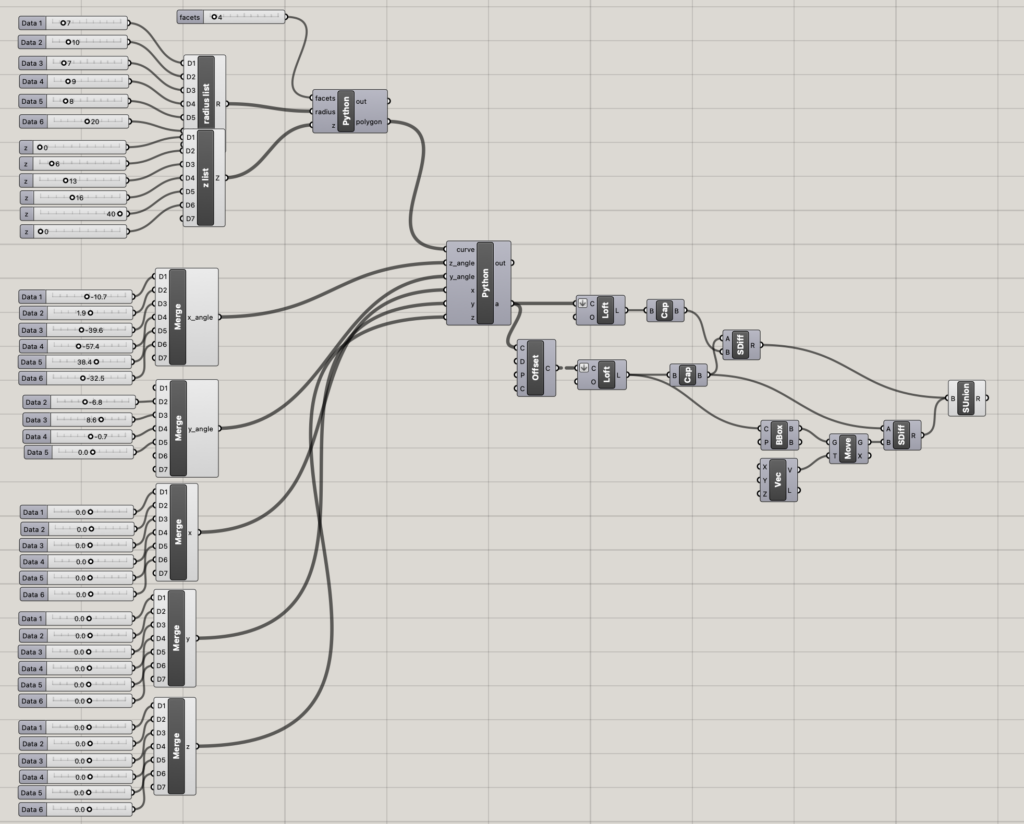

Design Process

In addition to the code we wrote in class for rotating around the z-axis, I added the ability to rotate the individual polygons on the y-axis, and translate them in the x, y, and z directions (I did not end up using the z translations, as we already set the z with our previous script when the points for the polygons are generated). I also added two more inputs for five total polygons that make up the outside of the In order to get a bottom of my vessel, I took a bounding box of the outside surface, duplicated and shifted it up by 2, then took a “Solid Difference” between it and a capped version of my outside wall. I then added this to my vessel shape with a “Solid Union” in order to generate my 3D vessel object.

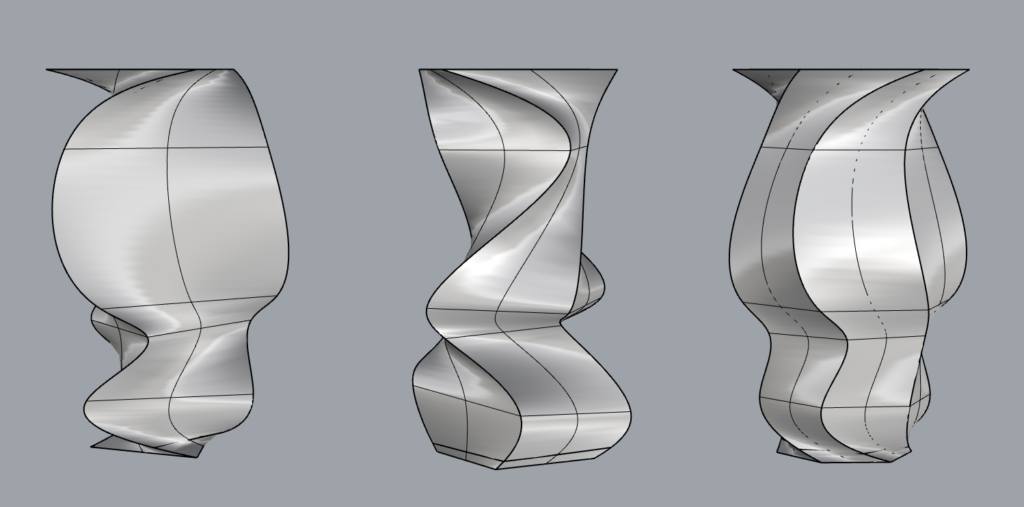

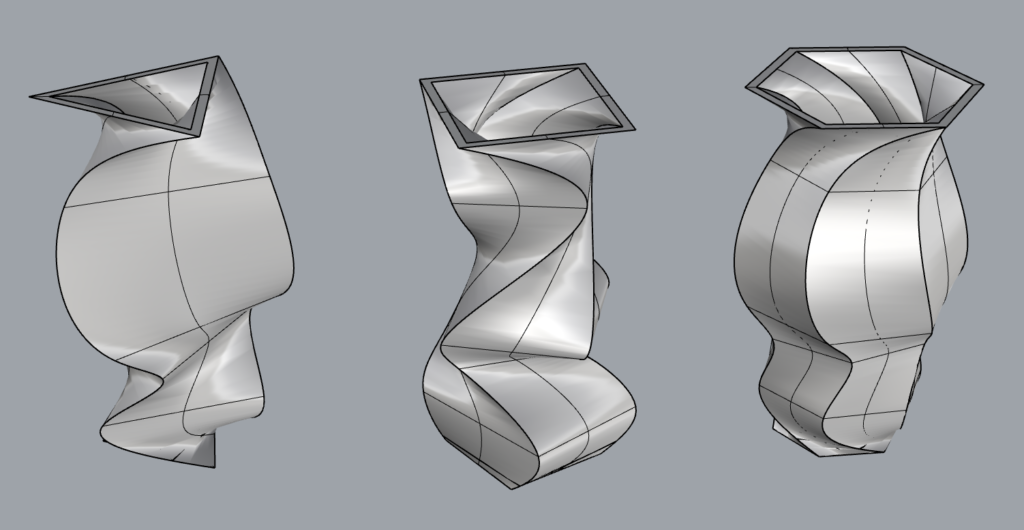

Rather than adjusting the number of facets of the shapes until they were circular or close to circular, I chose to keep them relatively small. I like seeing the polygon in the shape as it is manipulated. I produced the first model by adjusting parameters until I ended up with a shape, my triangular vessel, and decided I wanted all of my vessels to look related. The next vessel I designed has four facets, and the third has six. For each vessel I tweaked the rotation or x-y translation parameters on the polygons, but I kept the z the same.

I chose these forms because they almost look as if they are folding in on themselves. The curves of the manipulated polygons are very pleasing to me. I did not want a symmetric model for any of my forms.

Final Pieces

Printing Problems

I had initially planned to print in clear PLA, but quickly discovered that it would be difficult. After the first two layers, the clear PLA would stop sticking to the print and peel up, sticking to the nozzle and burning. Upon researching the issue, I discovered I was far from the first person to struggle with translucent PLA in 3D printing. Rather than spending a lot of time trouble-shooting the material, I switched to a white PLA that printed much more reliably. I might try to use the clear material in future projects, and test various temperatures to get a better result.

During my print of my second vessel, I realized the previous user of the PLA spool had tucked the end of the filament under the rest of the spool. As a result, when I checked in on my print it had stopped extruding material and the printer head was several layers above the portion of the model that had managed to print. I stopped the printer, untangled the filament, then started the print over.

Another interesting artifact resulted due to the choice of printer. My initial prints were done on the Creality Ender 3 Pro, and I hypothesize that either the motor or the belt need replacing due to a jitter that was noticeable during printing and produced the wavy lines on the surface. I actually like the way the lines look, but the printer also struggled with some of the more extreme angles in my models, as I did not end up printing the vessels with supports. Additionally, my triangular vessel suffered from being top-heavy, fell over, and a corner broke off. I reprinted my triangular vessel on a Prusa 3D printer, and the resulting structure was much smoother.

Reflection

Parametrically generating the designs allows me to more easily produce certain shapes. In many ways I find it significantly easier than trying to use any 3D design tools. Understanding the mathematics behind the form and design produce cleaner models, as well. I am not left with any floating points or odd holes in my mesh that need to be repaired. Sending these models to the slicing software was very quick.

I have always been of the mind that technical fields can be very creative. Just like any other tool artists use, it requires an understanding and a vision from the person using it in order to create something that can arguably be called art. Without me sitting at a computer for hours designing the program, the model would not have existed in the first place. The work is still there. There will always be advancements in techniques and tools in artistic fields, but they still require artists to utilize them in order to produce something.

Awesome Vessels Jaime! I really like the gestural quality of your pieces. They look like they are twisting and almost dancing. l know the wavy surface wasn’t intentional but I also really like it with these forms. It makes me think there are lots of possibilities for fun parametric surface decoration on the 3D forms.

Hello Jamie, I really enjoyed seeing your vessels. I also had problems with my filament getting tangled. On my second vessel I had to watch it and check on it every 30 minutes to make sure it doesn’t get tangled. Great Job!