Design Process

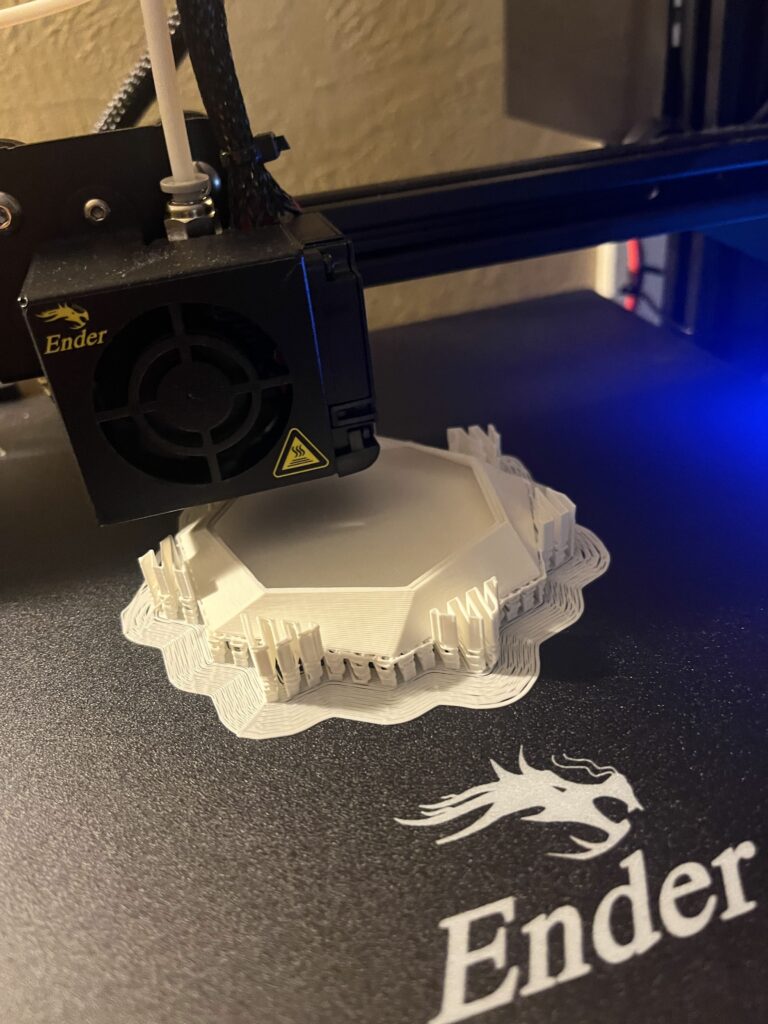

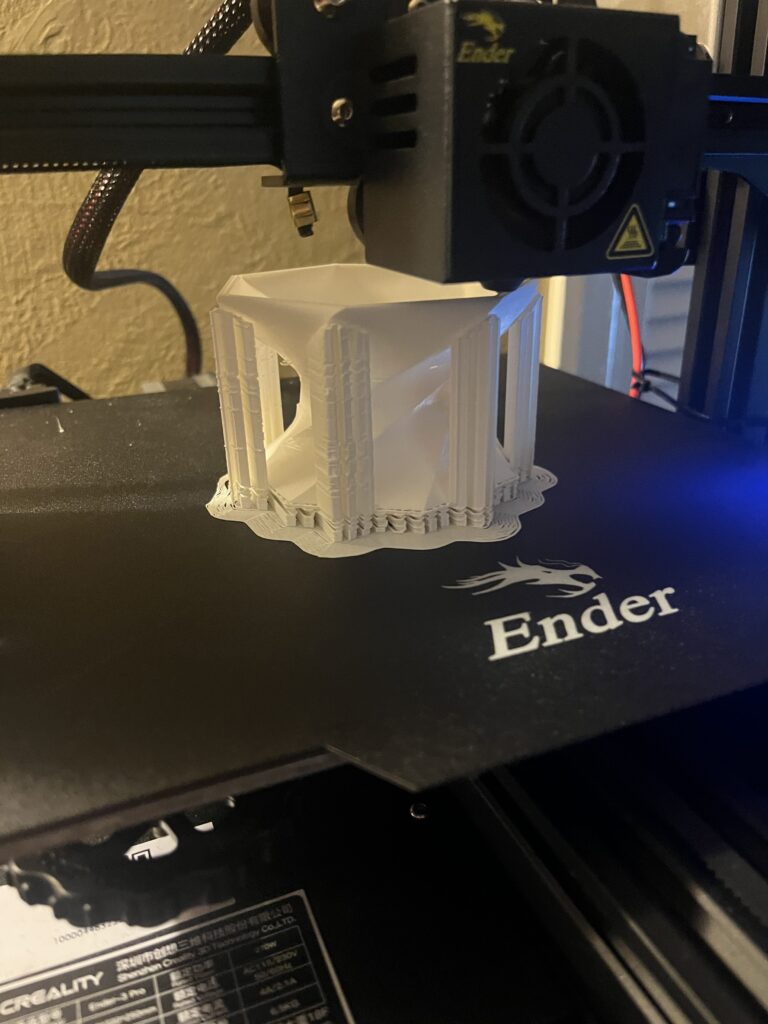

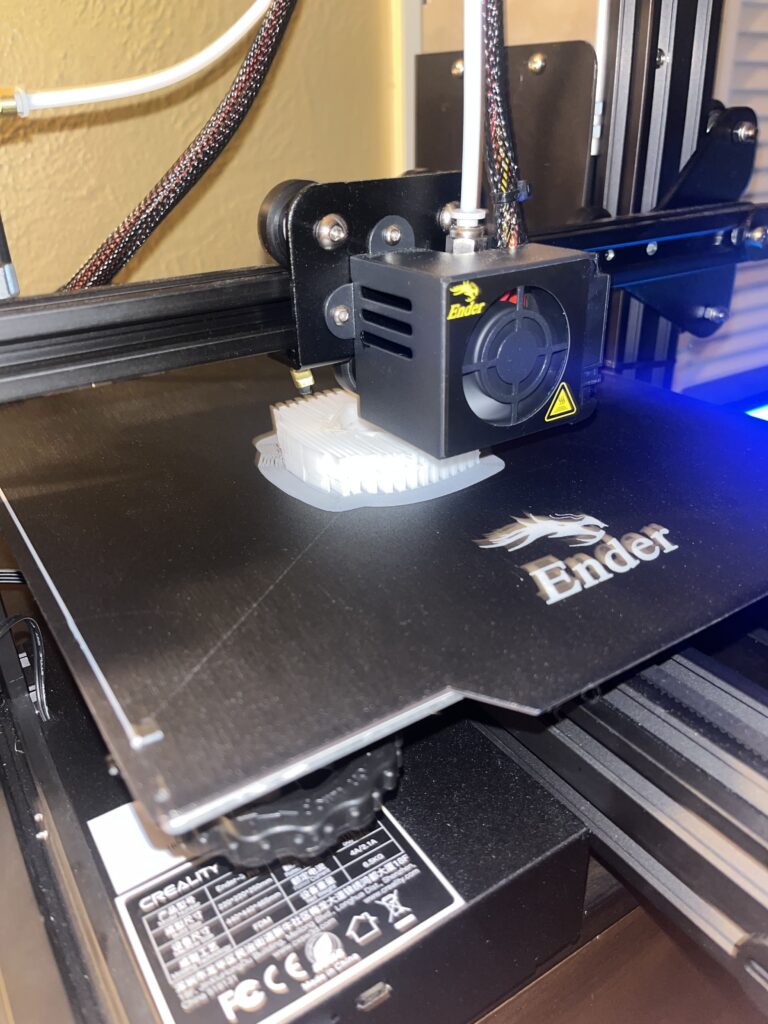

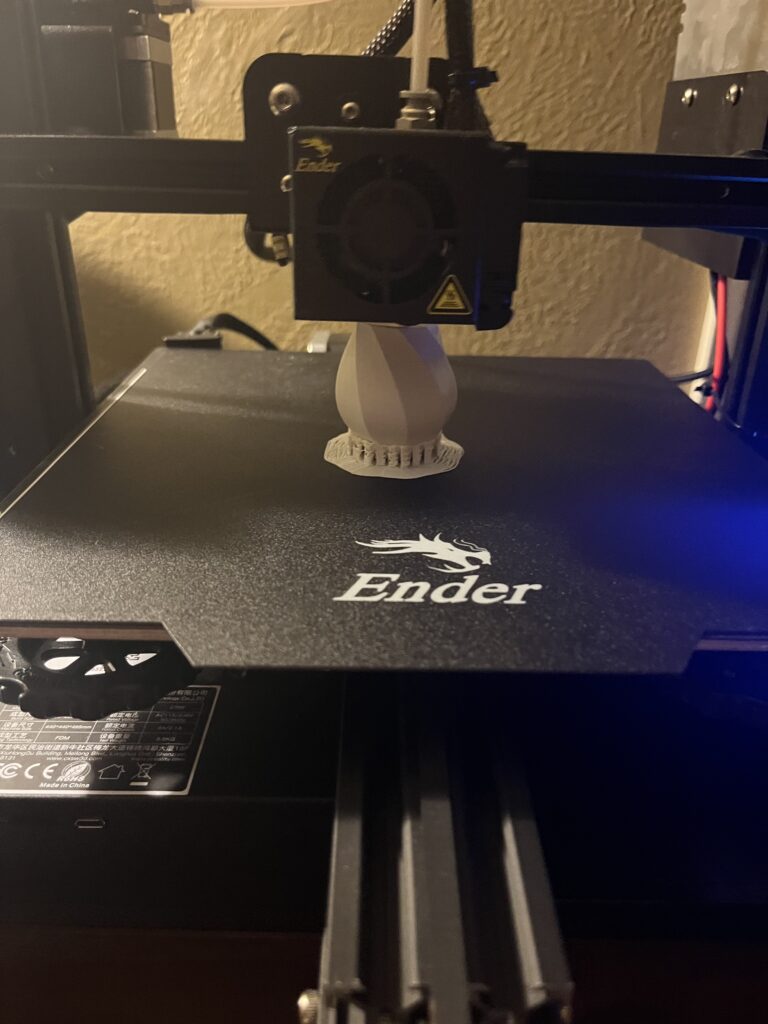

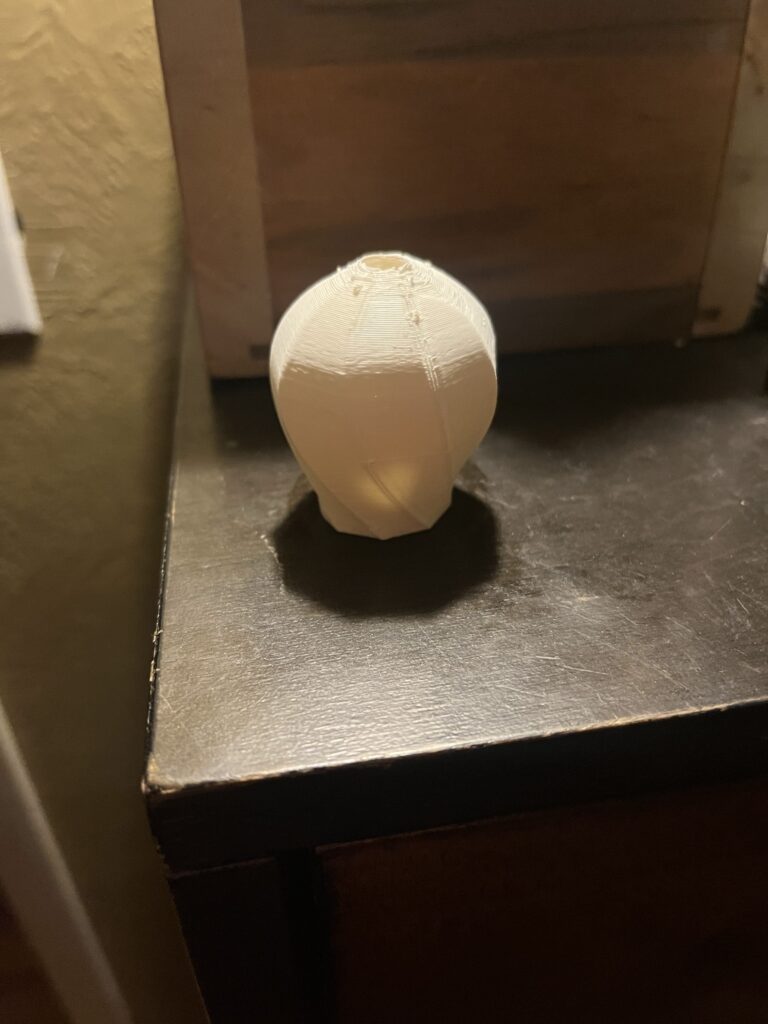

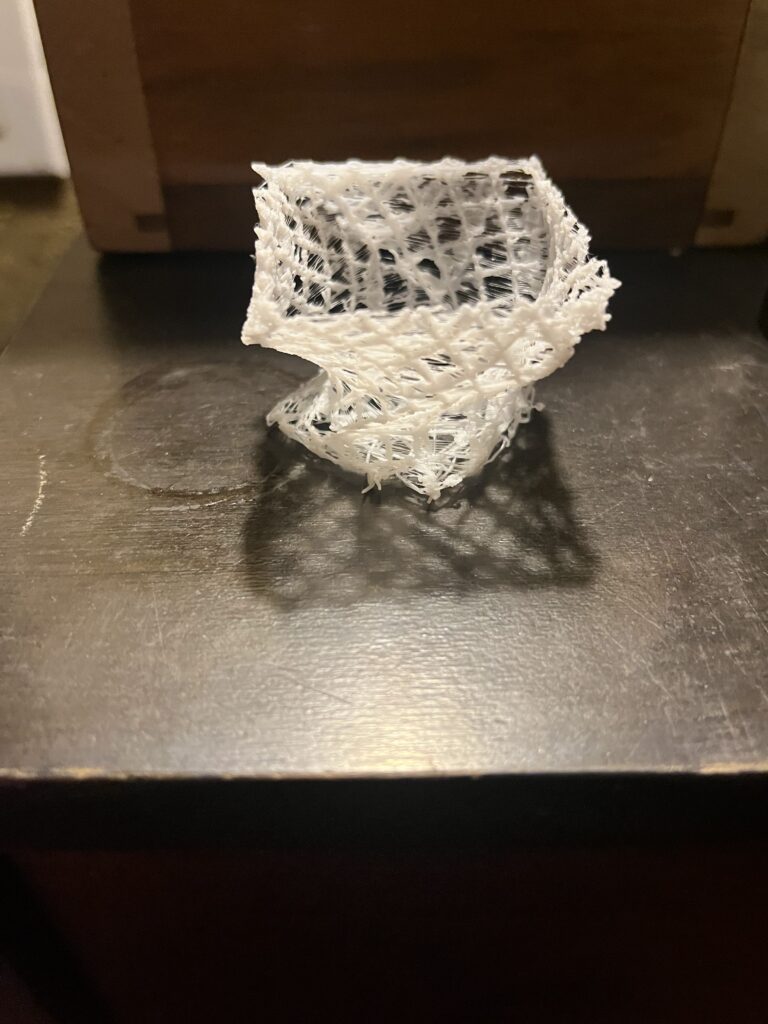

My overall design process wasn’t nothing to complicated. It was pretty much messing with design parameters until I found something really cool. One thing that wasn’t going well with the parameters is when I was adjusting them in grasshopper, the software kept freezing. I had to force close my rhino application just to go to it. Some of the other issues I had was, when I was doing my first print, it flew off the bed and fell down. I had to do some research and found in the Cura software, if you go to the printer settings you can add adhesion and supports. Once I added those options, it increased the time to print, but it made the print successful. A side effect of building the support is getting rid of the support once the print is complete. Most of the time it doesn’t come completely off and leaves some excess material on the print.

Reflection

The parametric design process is like a new superpower for creators. It combines computer programming and 3D printing to make things in ways that were impossible before. Instead of just drawing or sculpting, designers can use code to create rules and formulas that shape their designs. This means they can make things very precisely and with lots of details, like intricate patterns or structures. During my process of creating my 3 vessels, my family couldn’t get away from the 3D printer. They were so fascinated with it and just taking pictures of the process and the final product. My mom found so cool, that is forcing me to design some specific tools to help with her to make this certain middle eastern desert. Some of the advantages I think is the ability to actually create what you design with code. So if you are able to program the design, then you are able to bring that design into real life. Some of the disadvantages, is learning to actually code to design a parametric design in rhino. Most of the 3D printing designs I have seen are people creating the design with just some 3D modeling software. Overall the design process if quite exciting, if you are able to put in the work, you can make what you imagine into a reality.

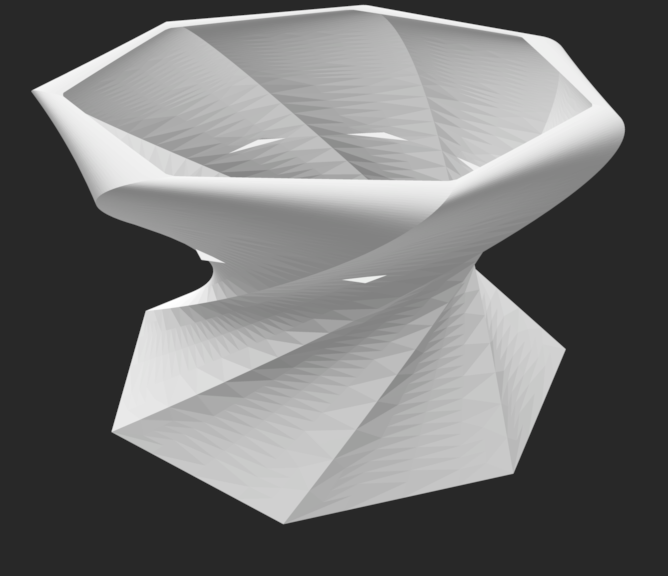

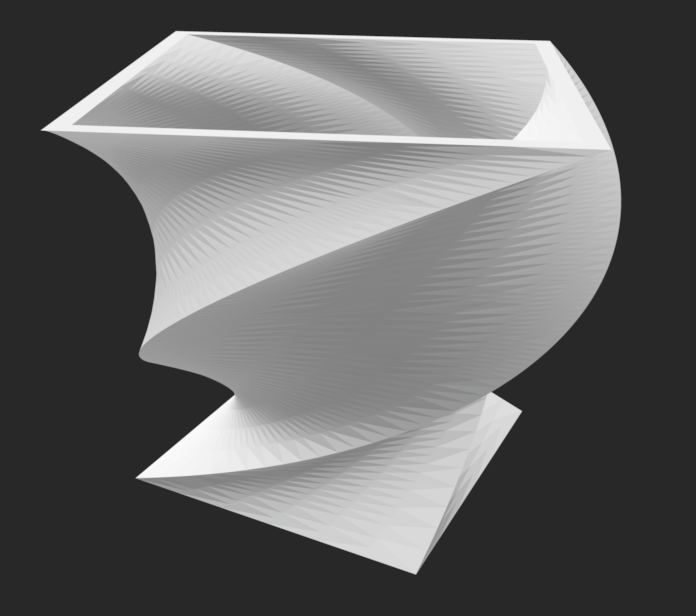

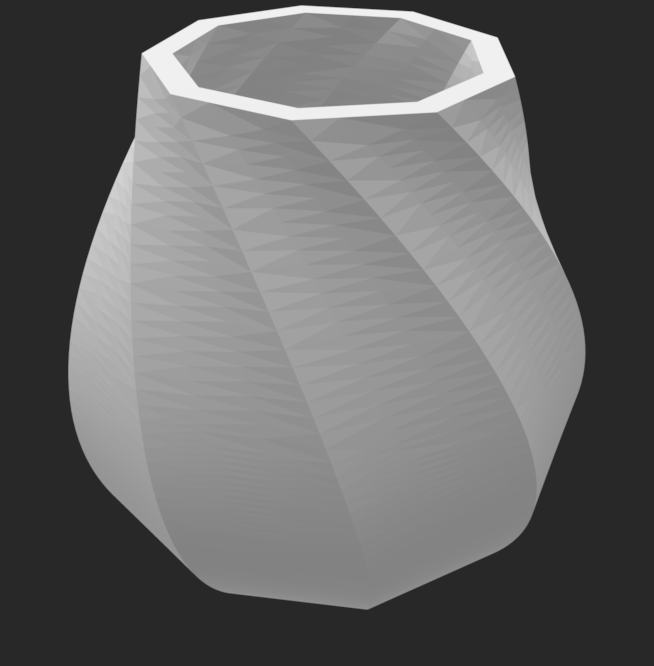

My general design process and intent was to find a cool design and print it. Unfortunately, I never had enough time to create a whole design program, so I had to use the code that we did together. I did alter the values of the angles a lot, the facets, and the position of all 3 pieces in each vessel. When designing my first one, my little brother wanted me to make a design the resembled the structure of a video game which is call Valorant, and its championship trophy. For my other 2 vessels, I just messed with parameters until I saw a design and that it was able to print without any issues happening. I do feel like I designed the the object, even though I didn’t fully write the code, I had to do the experimentation with the parameters to create the final design.

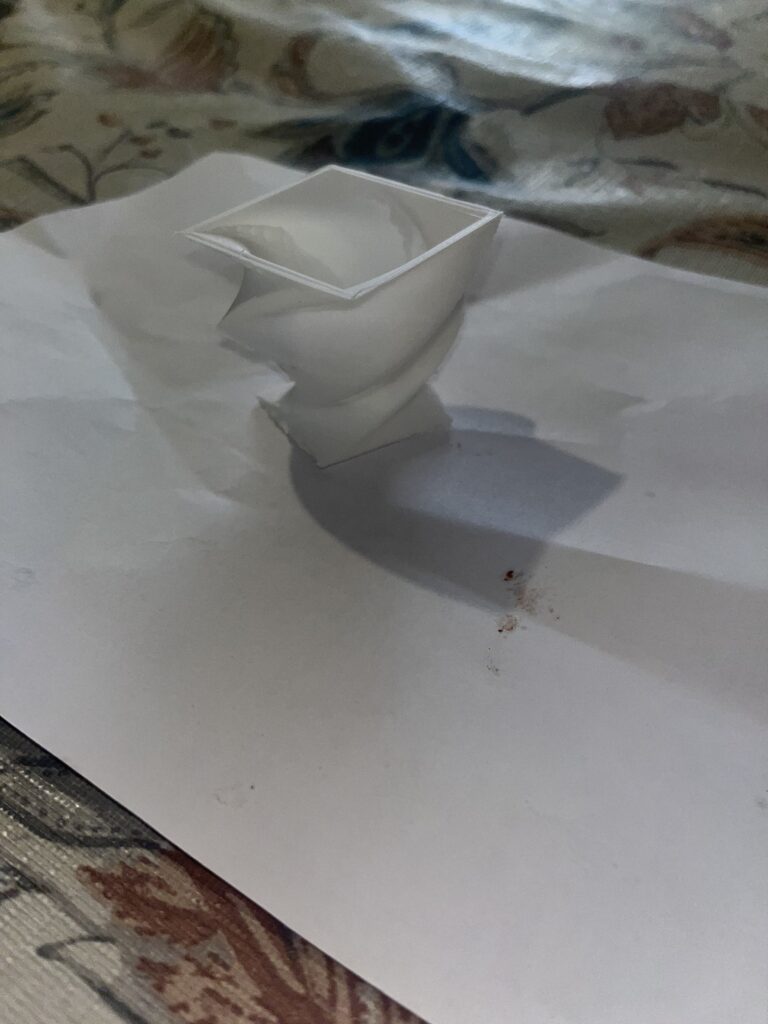

Here is a picture of some of the failures I had during the process, and a picture of the trophy I talked about earlier that belongs to the game Valorant.

Hi Atah, I really enjoyed your presentation and your vessels. I too was worried that while the vessels were printing they would be disturbed by my cats, dog or kids 🙂 The first vessel with the “funky” design looks very very neat! It’s like a delicate lace. I wish I could recreate the setting intentionally. Good job on your vessels and presentation!

Thank you! It was nerve racking when I would have leave and my little brother would stay home with my printer. I would have to call my other brothers to make sure he doesn’t mess with them.

Hello, Atah:

Good job, I believe if you made the shell thicker, we do not really need the supports. And I am also wondering are the supports easy to remove?

Hello Lin, the supports were easy to remove if it was a thick object. I had to squish the supports and then it would be easy to remove. The bad part was then the tips of the support that is connected to the actual vessel, those were the hardest ones to remove. I would have to use the scissors the come with the printer to remove them.

Hi Atah, I had the same issues with there being holes in my vessels. When I kept twisting the vessel it looked cool each time, but I guess became too twisted that the math had holes in it. Great job!

Thanks Nathaniel, I feel like if made the vessel have thicker walls it would be able to print without the holes. My whole time I wanted to have twisty objects.