Design

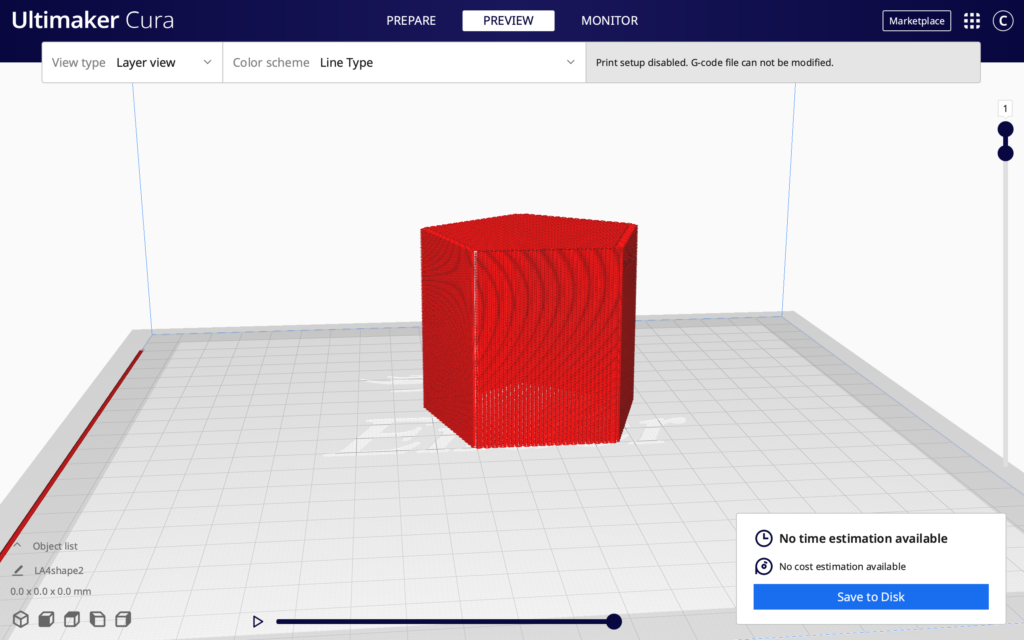

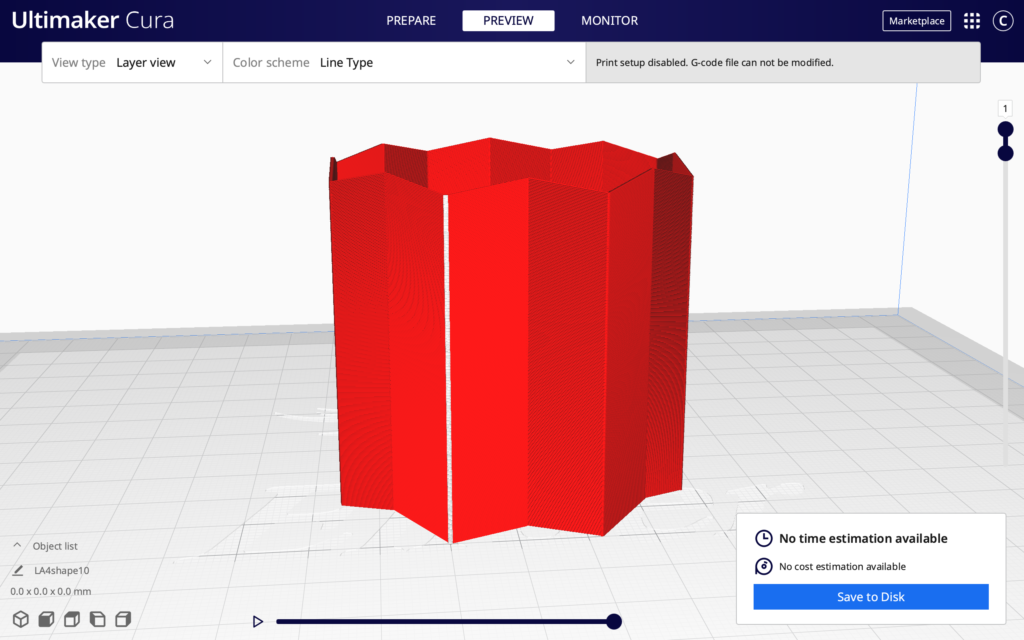

I decided to try to emulate the surface textures that we’ve seen in clay. I used the simple polygon code from class and modified it to provide the textures. I used the turtle library to step off the edge of the polygon at each step when drawing an edge so that the textures are drawn on the same plane and on both sides of the edge. I first drew an edge with a surface texture that is 1 mm. The surface texture on even planes starts with a right indentation or takes a right turn first in the eyes of the turtle, then comes back to the line and creates the texture on the opposite side. The odd plane iterations draw a left indentation first. The Rhino program to create this shape without a turtle would require each of the 250 planes for a 50mm object to be laid individually and create a surface out of all of those. Which I don’t know whether the result of lofting those surfaces would give us the desired effect or something smoother. Especially when sliced.

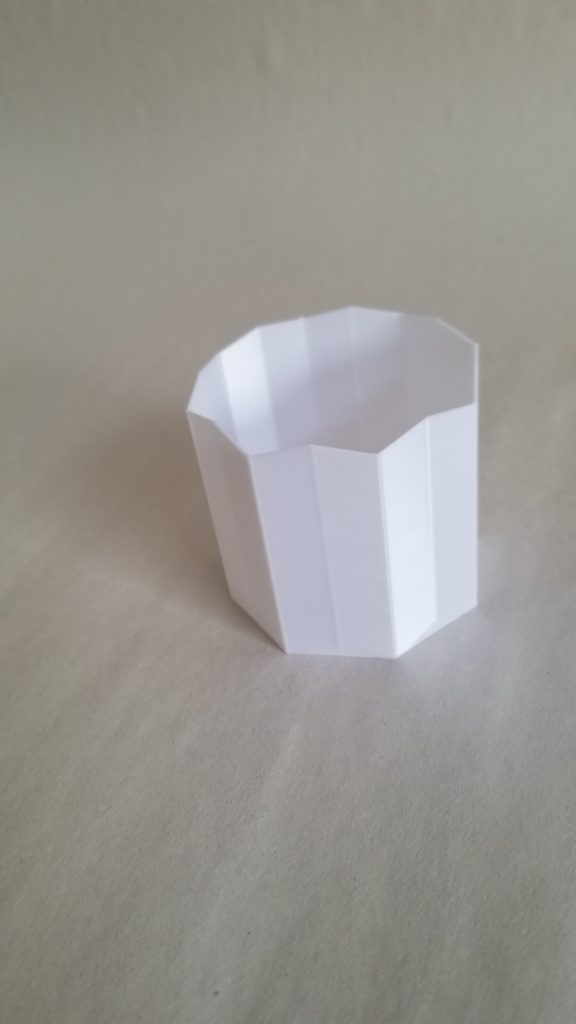

The surface texture on this print wasn’t very noticeable, but when holding it close enough you can see small indentations made by the weaving of the surfaces of the structure.

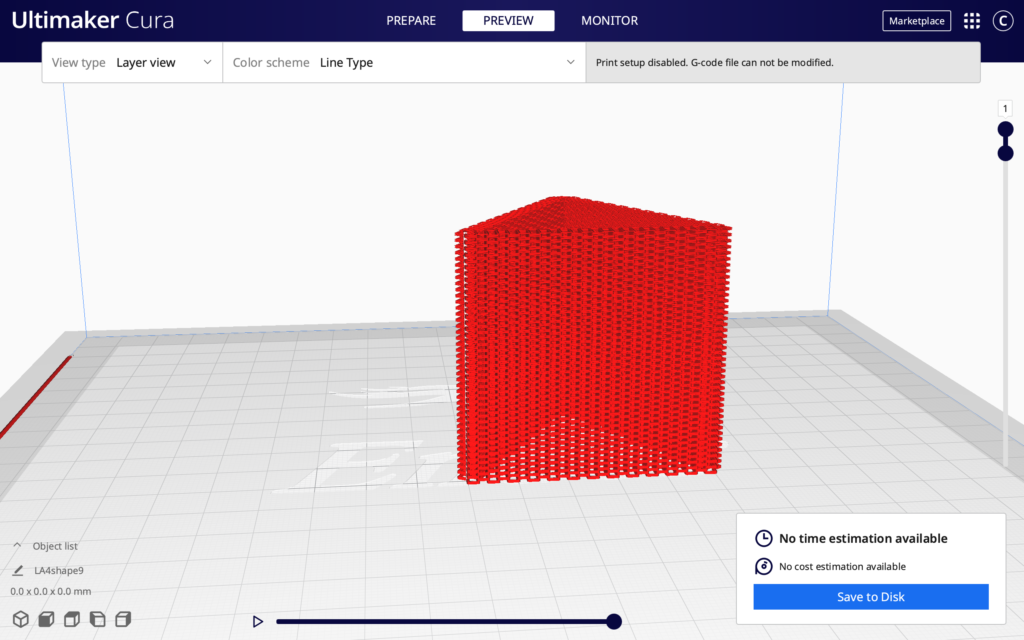

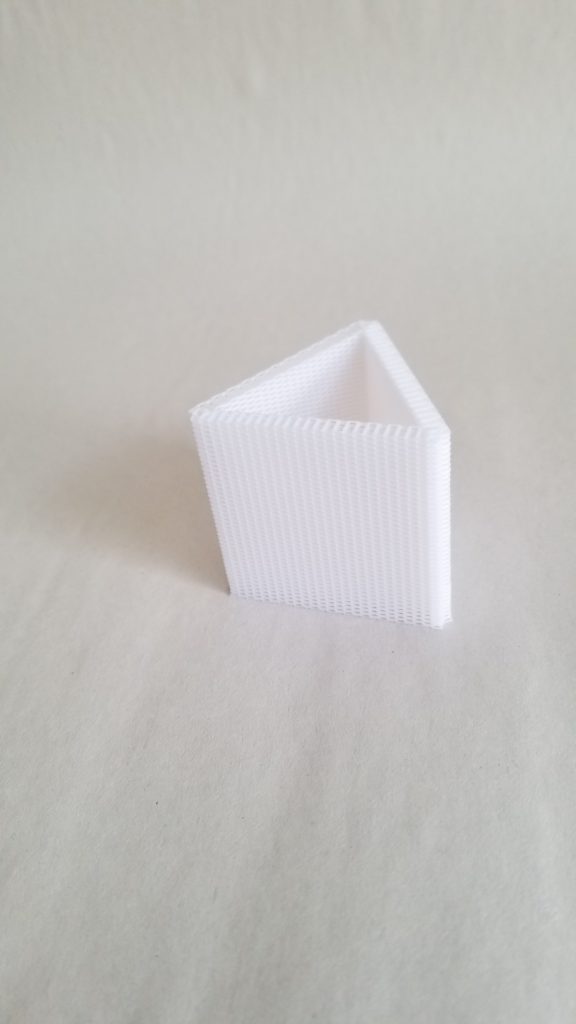

I changed the design to a triangle and made the indentation of the weaving larger, by doubling it to 2mm in each direction. This design made a more noticeable texture on the surface and left small holes in the surface.

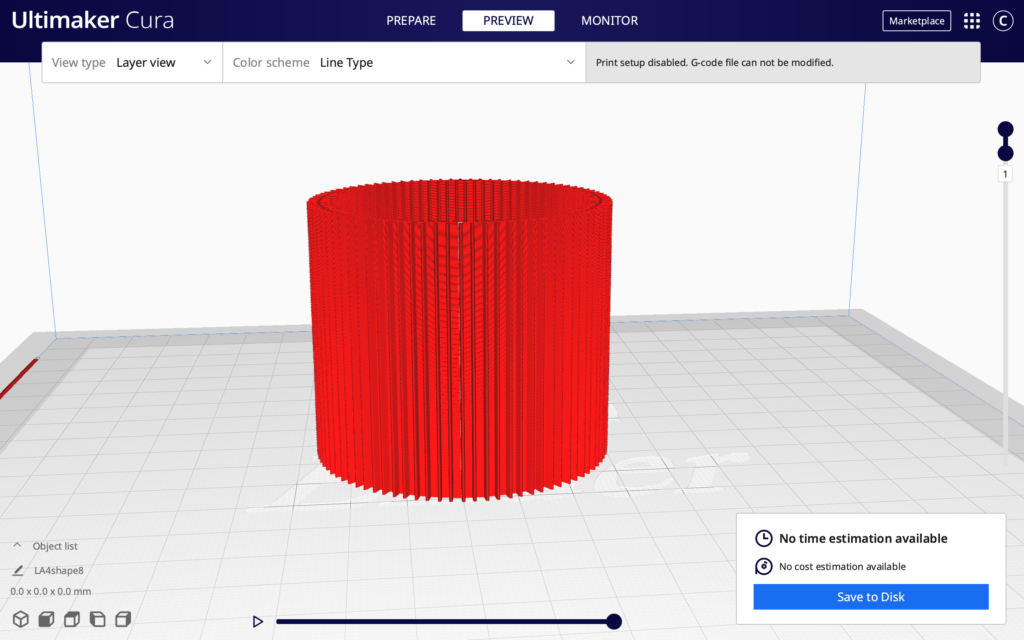

My second design uses a surface texture that moves directly out two steps and then on the same line moves back to the edge of the surface. Then moves one step forward and moves out in the same manner in the opposite direction. This was designed to hopefully emulated the print form class that is a flexible structure, so that you can squeeze the print.

My third design, I played with using a non-planar path for the edges of my print. At each step forward the turtle moves 0.2mm upward. After reaching the half way point of the edge, the turtle moves down by 0.2mm at each step. Non-planar paths cannot be generated by a slicer, because the slicer creates g-code that prints each plane individually, before moving on the z-axis.

Craig, all of your designs are very well constructed and clean. The texture on the triangle shape compliments the shape well. The cylindrical design looks really nice in Cura too. The way that you figured out to move the turtle in the particular steps worked really well to create the non planar path.

Thank you, I like the texture of triangle the best. Its like a cool chainmail or mesh

Hello! I really like your designs. I think that the “lattice”-like structures were some of the most interesting. The printing of the final designs seems to be extremely high quality and of great quality. With my prints, mine were a little flimsy.

Thanks, didn’t think of calling it a lattice, but totally fits! I was surprised that the lattice didn’t bend more as it was applied over the spaces, but the structure stayed really uniform and supported.

Super cool. I like the unique last shape you showed. Do you think you will continue to write your own GCode?

I might write some for ceramics if I can’t use a slicer to perform a flat fractal pattern. I do like the aesthetic of the ceramics as well, so writing code for some of those would be a fun project too.

Hey Craig! I really like that texture that you created on each of the 3D models. It’s clearly something you cannot generate with a regular CAD/Slicer pair. The model with non-planar paths also looks really good!

Thanks! Yeah I was trying of think of how to make geometries to represent the layers and a lot of it seems to hit that barrier of expression.