For large assignment 2, we were assigned to make a family of interesting vessels and print them using a 3D printer. Demonstrating creativeness and intuitiveness through computational modeling using Rhino and Grasshopper is the overall personal goal of the assignment.

I have never worked in a parametric process before this class so computationally fabricating models that we can turn into physical objects is very interesting. Creation this way is very different from the traditional process of art creation. Usually when creating art, I start with an idea and expand upon the idea. When computationally creating, it is almost like the opposite of the normal process. I tend to not start with any ideas and then generate models until I settle on one. The creativity really stems from thinking outside the box on the code that generates the model. Since I am very new to Grasshopper and Rhino, I somewhat tend to stay in the box with various little tidbits of creativity throughout the code. Creativity within the code could be changing the parameters of functions, adding new elements within the model, randomness, and much more. This brings a disadvantage to me because if I had expertise on how the programs like Rhino and Grasshopper work and more time to investigate various topics within the programs, then I feel like I would be able to be more creative. When traditionally making art, I feel like I can be creative without the expertise on a subject. I am not a great painter, but I know how to be a creative one and I personally do not feel the same when computationally generating art. This also gives me more of a reason to continue to improve my knowledge upon these programs and in the topic of computational fabrication in general, so I can feel the same way about this process as I do with the traditional process.

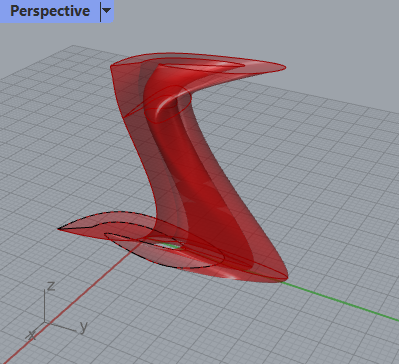

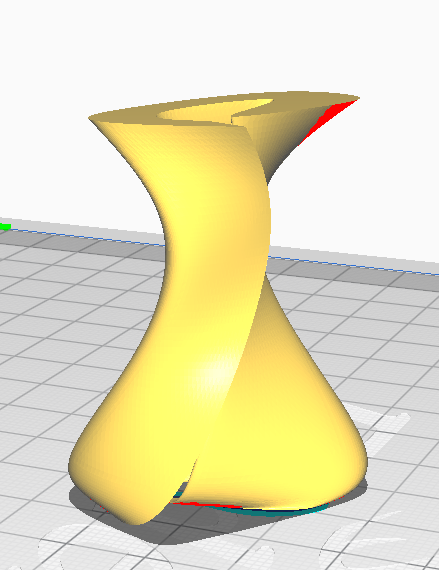

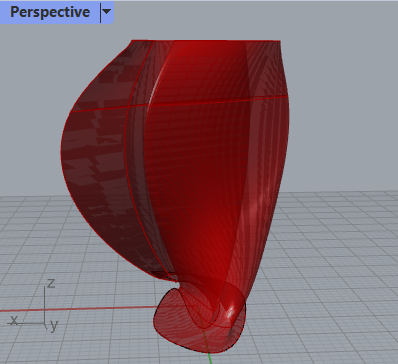

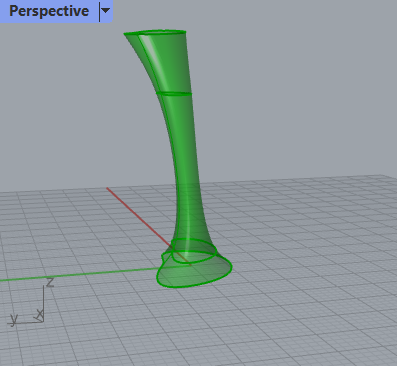

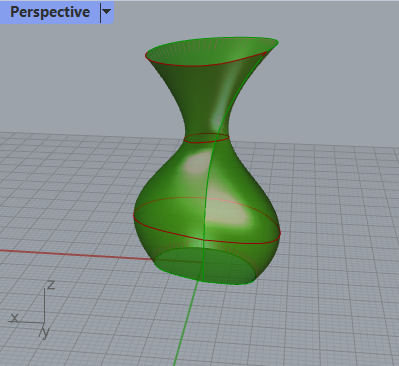

When starting the modeling process, I initially did not have a thought-out design in my head but decided to continuously change the code that generates the model to find an interesting model. To achieve this goal, I built off the example that was demonstrated in the class that generated multiple curves and created vessels based off the scale, rotate, and transform python functions. Making a sketch of an interesting, but printable, shape was the first step and I tried countless new and fascinating shapes. Along with trying new sketches, I would manipulate the Python code block to create an appealing vessel to go with the sketch. Adding curves and changing parameters to each curve’s functions allowed for the creation of new and potential vessels. Most of the vessels I settled on had four or five curves. To create a consistent vessel, I would only slightly change the parameters values, meaning that my bottom curve would have an X-axis value of 10, then the middle curve will have an X-axis of 20. This would create the curvature of the vessel and allow for more intriguing shapes. Here are some cool designs I found throughout my creation of the vessels. I was looking to create objects that had a curvy build and resembled lamp-like pillars.

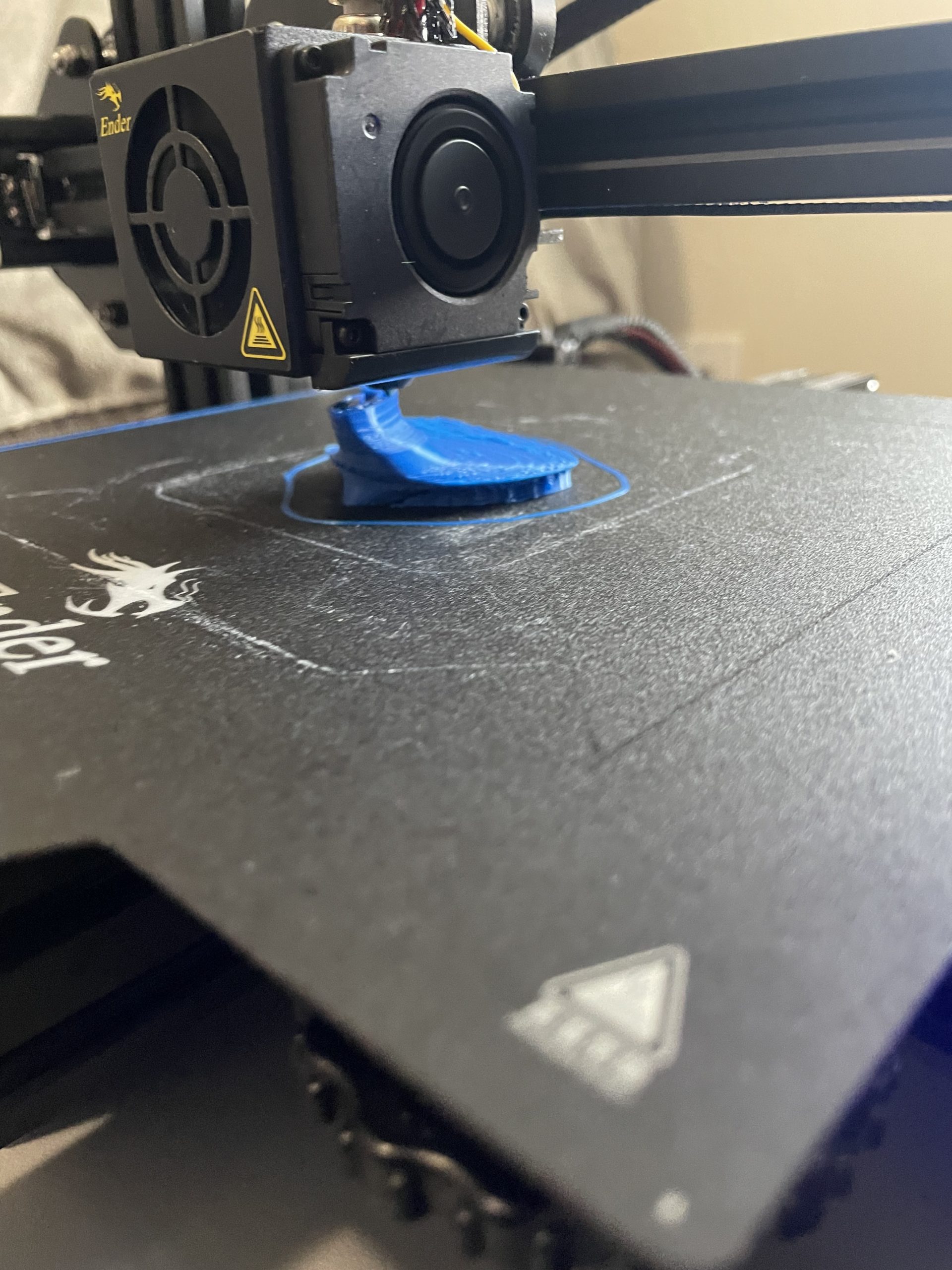

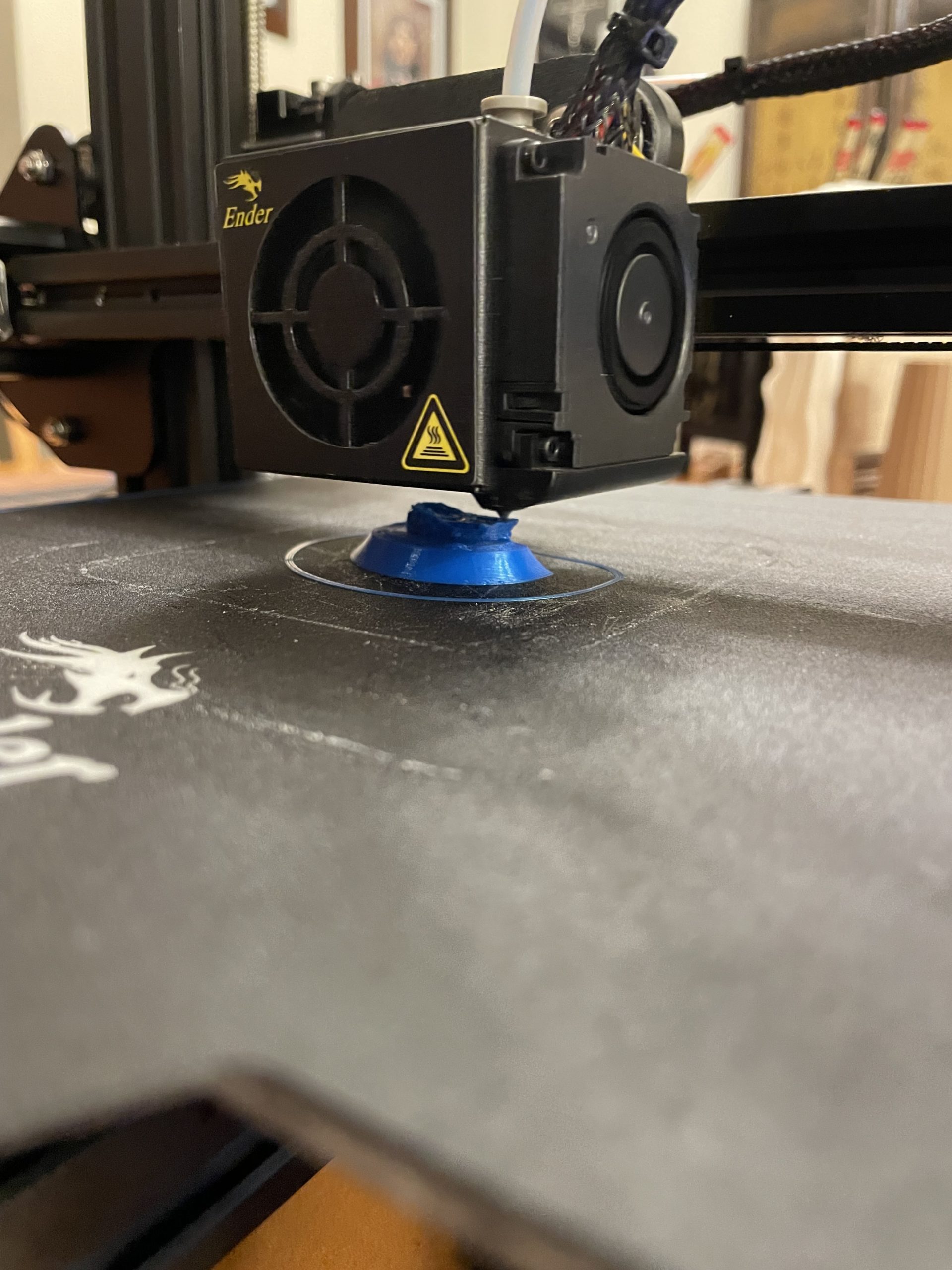

Originally, I created some amazing vessels that I was very excited to print but was unfortunately unable to succeed with some. Issues involving my printer and the complexity of the model were the downfall to some of my vessels. Creating vessels with very complex curves allowed for the most interesting models but was a nightmare for the printing. The models below show the one of the original models I wanted to create and the print for the model. As you can see below, the print was not what was expected. The models kept turning out very surprisingly short, which was due to a loose Z-axis rod on the printer. After fixing that, I then had some issues with the filament I was using which was a quicker fix by changing the filament back to my original white one. Unfortunately, these were not the only issues. There were times where I would print and then the system would lose track on where the extruder head was, and the interfaces would flash question marks for the X, Y, and Z coordinates. This error stopped about four of my prints and sometimes even about 70-80% of the way through the print.

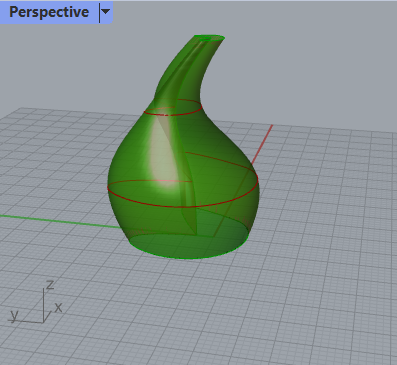

There were frustrating times with these prints, but at the end of the day everything turned out fine and the printer is now running at a functional level. The final models I settled on contained a big base and a non-complex scheme. I settled on these forms because they contained minimal complexity, while still keeping true to the intended design of the original models. Since most my complex models failed printing, I resulted to making some less intense models that allowed for a better physical print. Two of the models generated allowed for some great vessels. Unfortunately, one of the models stopped around 80% through the print and another stopped about 20% of the way. I improvised and combined the two into the mushroom-shaped print by gluing the 20% print on the 80% print. Issues were occurring and I had time to print out another 100% print of the model, but I like how the two combined into something very different from what was intended so I decided to stop at these three models below.

Overall, this was a fun assignment. There were issues and frustration, but I mostly had a good time while designing the models. Computationally generating art is amazing, and I do feel some sort of authorship with these pieces. They are unique to my design, but I would feel more authorship if I fully generated the algorithm that created the pieces. Looking forward to the next one!

Link to my assignment zip file: https://handandmachine.org/classes/computational_fabrication/wp-content/uploads/2022/02/DamianFrancoLA2.zip

I love your avocado/gourd shape with the wedge cut out. It is so simple, yet so elegant.

Nice creativity in taking some failed runs into something that is unique and fits the family. It seems like there were lots of problems for everyone in the class when it came down to too complex or oddly shaped designs.