Durability of Conductive Materials

Over two years, we conducted a series of durability tests on different conductive materials and electrical connection methods. A paper on our work was published in the IMWUT journal.

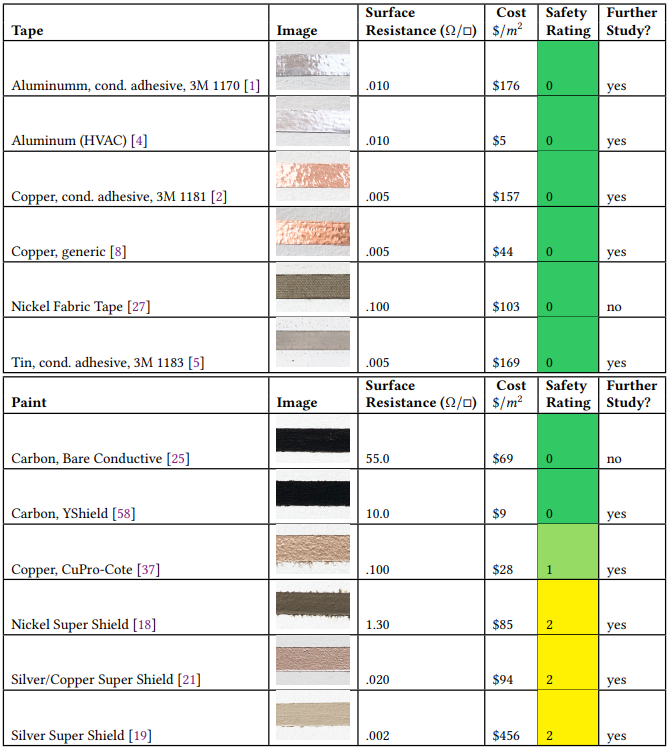

The paper analyzes a collection of conductive paints and tapes and compares their electrical conductivity, durability, appearance, and cost. We investigate different means of connecting these materials to each other and other electronic components–including connection via solder, conductive epoxy, conductive adhesives, and metal mechanical fasteners. We explore different means of insulating and protecting materials and provide the results of a range of durability tests. The results are discussed in the context of the development of interactive murals–large outdoor interactive surfaces that are intended to function for years. We identify two conductive paints, CuPro-Cote and Silver/Copper Super Shield, and two conductive tapes, Copper and Tin that are highly conductive, stable across most of our testing conditions and, we believe, suitable for interactive murals.

Years:

2022 – Current

Collaborators:

Leah Buechley and Alyshia Bustos

Publications:

Leah Buechley and Alyshia Bustos. 2024. Characteristics of Conductive Paints and Tapes for Interactive Murals. Proc. ACM Interact. Mob. Wearable Ubiquitous Technol. 8, 3, Article 92 (September 2024), 34 pages. https://doi.org/10.1145/3678587

MATERIALS

This study is motivated by our interest in identifying conductive materials suitable for building interactive murals–large-scale painted interactive surfaces with embedded circuitry that are outdoor, long-term installations. We want materials that are non-toxic, easy to apply, and, as much as possible, we want to integrate them into traditional mural painting practices. With these desired features in mind, we investigated six tapes and six conductive tapes and paints. From our preliminary investigation we narrowed our materials to the YShield, CuPro-Cote, Silver/Copper, Nickel paints and the aluminum, generic copper, and tin tape.

CONDUCTIVE AND INSULATING PAINT

We tested conductivity as a function of coats of paint for Silver/Copper, CuPro-Cote, YShield, and Nickel, using a substrate of primed Mural Paper. We also conducted a second set of tests to better understand the variability and long-term stability of the four paints. From these tests conducted it is clear that Nickel paint is not a viable material to use in long term installations or applications. It is also significant that CuPro-Cote and Silver/Copper are stable conductors over long time periods. These studies also indicate that larger surface areas of paint improve conductivity and lessen variability.

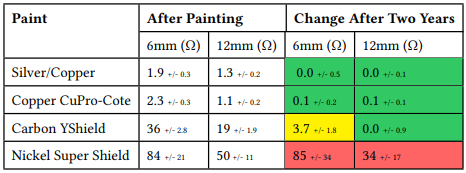

Conductivity After Two Years

We conducted a set of tests to better understand the variability and long-term stability of the four paints: Silver/Copper, Copper CuPro-Cote, Carbon YShield, and Nickel Super Sheild. We painted ten lines of each material at 6mm ( 1/4″) and 12mm ( 1/2″) wide. All lines were 300mm ( 12″) long and painted with four layers of paint.

The “After Painting” columns in the below table show the results of these tests, with paints sorted by conductivity. Immediately after painting, Silver/Copper is the most conductive paint and Nickel the least. CuPro-Cote and Silver/Copper are significantly more conductive than YShield and Nickel. For all materials, resistance and variance decrease with the width of painted lines. This makes intuitive sense. As surface area increases so does conductivity. The likelihood that any small localized variation in conductivity will dramatically impact the conductivity of the entire sample also decreases as the surface area increases.

The painted samples were then stored for two years and their conductivity was remeasured, see the right-hand columns in the table above. The samples were stored indoors on a flat shelf inside of a folder. The conductivity of three out of the four materials remained fairly stable over the two year time period. The small changes observed for Silver/Copper and CuPro-Cote are not significant. The resistance for YShield lines increased significantly (10% (p-value .02)) for only the 6mm lines. For both the 6mm and 12mm lines of Nickel paint, the resistance increased sharply. The 6mm Nickel lines experienced a 100% increase (p-value .001), and the 12mm lines a nearly 70% increase (p-value .001). A gradual darkening of the color of the Nickel paint over time was a visual clue to this degradation. It is well established that Nickel tarnishes in air. While Copper and Silver are similarly subject to oxidation, CuPro-Cote and Silver/Copper contain ingredients that inhibit corrosion.

It is clear from these results that Nickel paint is not a viable material to use in long term installations or applications. It is also significant that CuPro-Cote and Silver/Copper are stable conductors over long time periods. These studies also indicate that larger surface areas of paint improve conductivity and lessen variability.

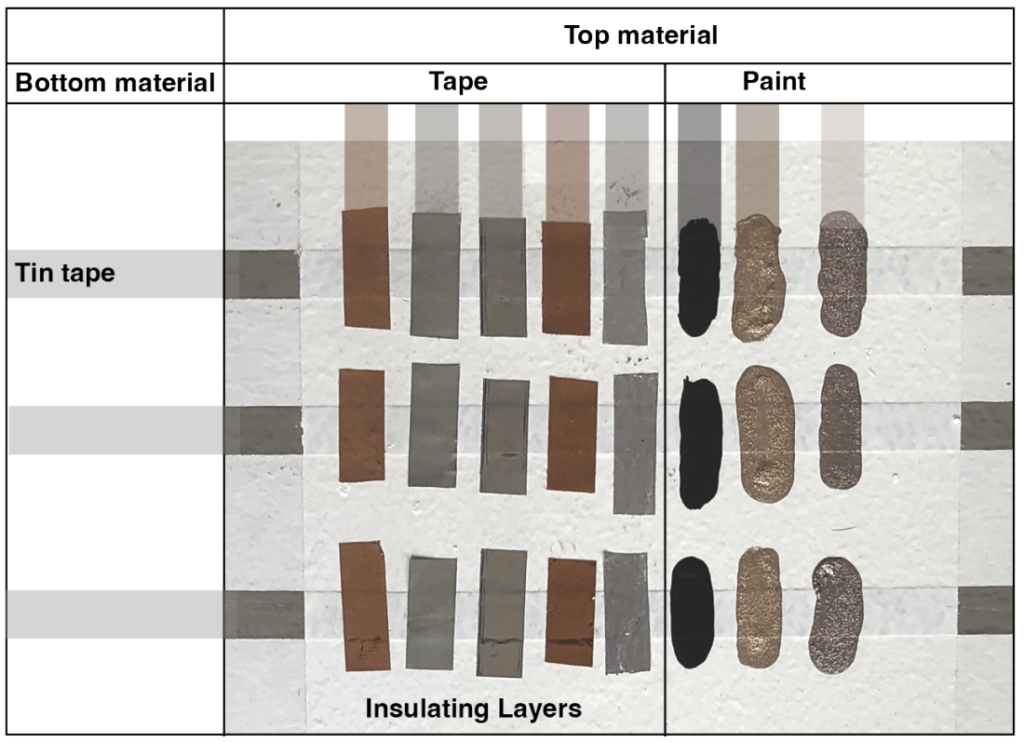

INSULATING PROPERTIES OF NON-CONDUCTIVE PAINT

When using conductive surface treatments, and conductive paints in particular, it seems reasonable and desirable to use traditional (non-conductive) paint as an insulator. Conductive and non-conductive paints are easy to combine and layer in interactive murals. However, based on preliminary experiments, it was not clear to us if non-conductive paint can be reliably employed for this purpose. We conducted tests to determine if and when it can.

There are 48 possible conductive material combinations, six insulating conditions, and three samples for each condition for a total of 864 samples. We used a multimeter to detect electrical connections between insulated layers. We determined a sample was adequately insulated only if all three samples for the given configuration, as well as all samples with additional insulating layers, had no electrical connections—that is, the multimeter was unable to obtain a resistance reading between the two materials. Since resistance is a function of electrical current, our results must be understood in the context of low-current applications only.

Our experiments indicate that, for metal foil tapes, the only property that is important when used as a bottom coat is the metal variety. The only property that is important when used as a top coat is whether or not the tape has a conductive adhesive. We found that non-conductive paint can function as an insulator between two layers of foil tape and when applying foil tape over conductive paint. In these scenarios at most three layers of house paint were necessary to insulate materials.

However, we found that extreme caution should be taken when employing paint as an insulator when conductive paint is applied as a top coat, particularly when it is applied over a bottom coat of conductive paint. We also found that visual appearance is not a reliable indication of insulation. That is, a conductive material can visually appear completely covered before it is electrically insulated. We do not recommend using non-conductive paint as an insulator between any conductive paint layers. We also recommend that non-conductive paint be used as an insulator only in very low-current applications like passive sensing. If traces will be used as general purpose conductors, i.e.: to connect power supplies or actuators in a circuit, non-conductive paint should not be used as an insulator.

ELECTRICAL CONNECTION TESTS

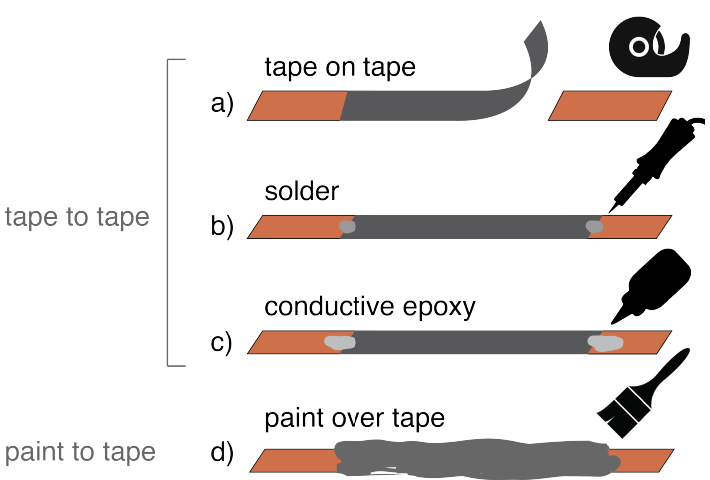

Establishing reliable connections between one material and another can be challenging, as can attaching standard electronic components to different materials. Of the materials we considered, only the copper and tin tapes can be soldered. Other types of connections can be made by painting over connection points with conductive paint, gluing them with conductive epoxy, and attaching them with conductive z-tape.

However, there is essentially no published information on the reliability or durability of most of these connection methods. We are interested in determining which types of connections withstand the kinds of stresses that electronics deployed in interactive murals are likely to face.

Test Set-Up

To explore these questions, we developed a set of connection methods that employ tape (with both conductive and “generic” adhesives) image above a), solder b), conductive epoxy c), and paint d). We used methods a)-c) to make connections between different conductive metal foil tapes and method d) to make connections between conductive paints and tapes. We note that this is not an exhaustive survey of all possible connection methods.

We developed testing procedures and companion hardware and software that allows us to track conductivity over time. Our testing hardware is based on the Adafruit Adalogger, a SAMD-based microcontroller, with an onboard SD chip. We measure the change in resistance for materials and connections over time using voltage dividers. Our connection tests were conducted on test strips of primed Mural Paper measuring 80mm ( 3.5”) wide by 360mm ( 14”) long. Generic copper tape was applied as a base layer. We tested connections between this base layer and a top material. The top material occupied 100mm ( 4”) in the center of the strip. It was attached to the copper base layer via 6mm of material overhang on either side. That is, tapes and paints were applied 6mm over and on top of the copper base layer on either side of the 100mm to test their connection to the base.

Freezing Test

We are interested in building murals outside where they will be subject to freeze and thaw cycles, so we explored material and connection sensitivity to freezing and thawing. For this test, resistance and temperature measurements were again taken every 500ms. We put samples in a freezer (temperature -5°F) for two hours and then removed them and let them return to room temperature ( 80°F). Before being placed in the freezer, the samples were left at room temperature for 10 minutes to obtain base readings for resistance and temperature.

Water Immersion Test

We are also interested in understanding how materials react to water. To investigate this characteristic, we submerged samples in water for 10 minutes and then removed them and allowed them to air dry, recording resistance changes during this process. For this test, when we submerged multiple samples simultaneously, we were unable to get meaningful readings; because water is electrically conductive, when multiple samples are submerged, measurements from different samples are not isolated. Due to this limitations, we used a single sample for each material. Because of the more limited data, results should be interpreted with caution.

Connections After Two Years

To understand how different connection methods wear over time, we created a set of test strips and stored them for two years indoors on a flat shelf inside of a folder. We measured the conductivity of each sample at the beginning and end of this time period. The most stable connections for tape are made through soldering. These connections experienced no measurable change in resistance over time.

Conductive epoxy, which we used to connect Aluminum tape, since it cannot be soldered, degraded slightly. Tapes attached with conductive adhesive did not remain reliably connected over time. Generic adhesive was not a viable long-term connection mechanism either. For paint, connections made by painting CuPro-Cote and Silver/Copper over conductive tape we.

OUTDOOR DURABILITY

We further tested the durability of connections and materials by placing test boards in an exposed outdoor environment for extended periods of time. These tests were motivated by our interest in creating durable outdoor interactive murals. We also believe that these harsh conditions provide useful information for applications that may not need to withstand such extreme conditions. We conducted a series of long-term durability tests over the period of approximately one year, gradually improving our testing methodology and hardware during that time.

Test boards were created from primed sheets of 300mm × 300mm (12” × 12”) fiber board (MDF). Materials and connections were applied to the front of the board and testing hardware was placed on the back. Testing hardware was protected with a sheet of waterproof vinyl. Each board had 24 samples and one microcontroller The boards also contained BME680 temperature and humidity sensors. Resistance, temperature, and humidity readings were logged once per minute, for a sampling rate of 1440 readings per day.

DESIGN RECOMMENDATIONS

Based on the tests we conducted, we have identified a collection of materials and connection methods that can be used to build robust interfaces that can withstand significant long term and outdoor exposure. See table below:

We conducted a range of tests to determine the durability of conductive tapes and paints under different circumstances. We have explored how materials and connections wear when subject to freezing, water immersion, and extended indoor and outdoor exposure. We have exposed problematic materials and methods. Taped connections (made with conductive or generic adhesives) are highly unreliable. Nickel paint, which has been used in previous interfaces, corrodes rapidly.

We have also identified suitable materials and connection techniques. Silver/Copper paint, Copper tape, and Tin tape all have low resistance and remained quite stable across all of our tests. CuPro-Cote remained stable for all but the outdoor durability tests. We believe that these four materials can be used successfully in interactive murals as well as other interfaces that require long-term durability